The Lousy Hunter

Member

- Joined

- Jan 18, 2021

- Messages

- 12

- Reaction score

- 4

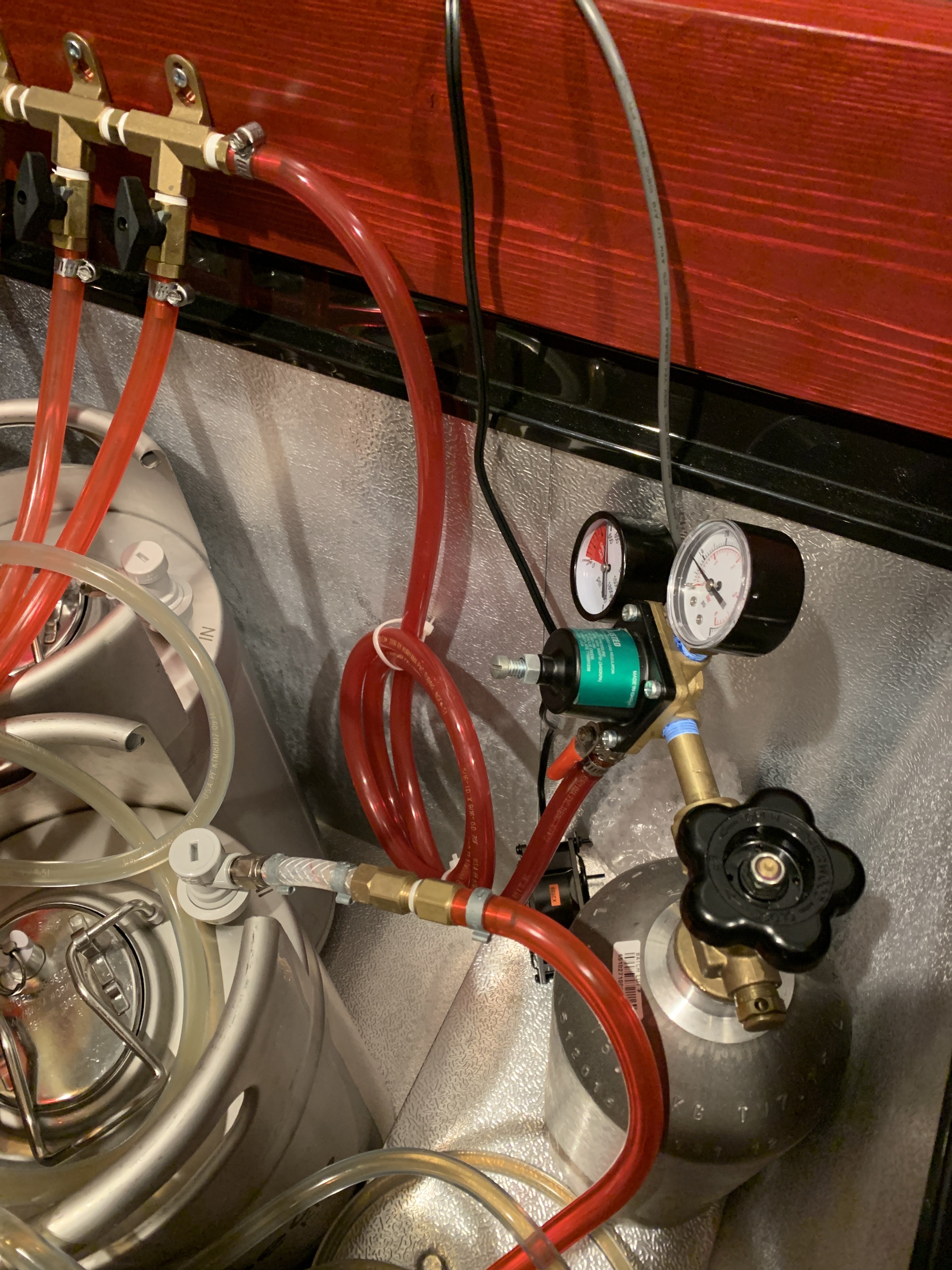

I’m having an over carbonation issue with my keezer. I could write a novel with the challenges over the last year. But I’ll skip it, and just jump to the facts. I would really appreciate some assistance on where to go from here. I built a straightforward keezer a little over a year ago. It’s a basic collar type setup. I have a four way manifold connected to a co2 tank with regulator (kept inside the freezer). I have about 6ft of line on the beverage side. Foam isn’t my issue, just over carbonated beer. I set the regulator to 11 at 40 degrees. I should note I suspected the regulator at one time. I’ve replaced it and no change. I force carbonated using the set it and forget it method. I serve and carbonate at the same time without touching anything. I recently degassed all four kegs and it brought them down to a reasonable carbonation. I then put the gas back on, only at 8 psi. Crap, one week later at 8 psi... over carbonated again. Any thoughts, ideas?

* side note. As I’ve been dealing with this I carbonated a single beer in my other freezer that I normally use for fermentation. Hooked up a cobra tap. Awesome beer and perfectly carbonated. This was with the regulator I replaced in my keezer.

* side note. As I’ve been dealing with this I carbonated a single beer in my other freezer that I normally use for fermentation. Hooked up a cobra tap. Awesome beer and perfectly carbonated. This was with the regulator I replaced in my keezer.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)