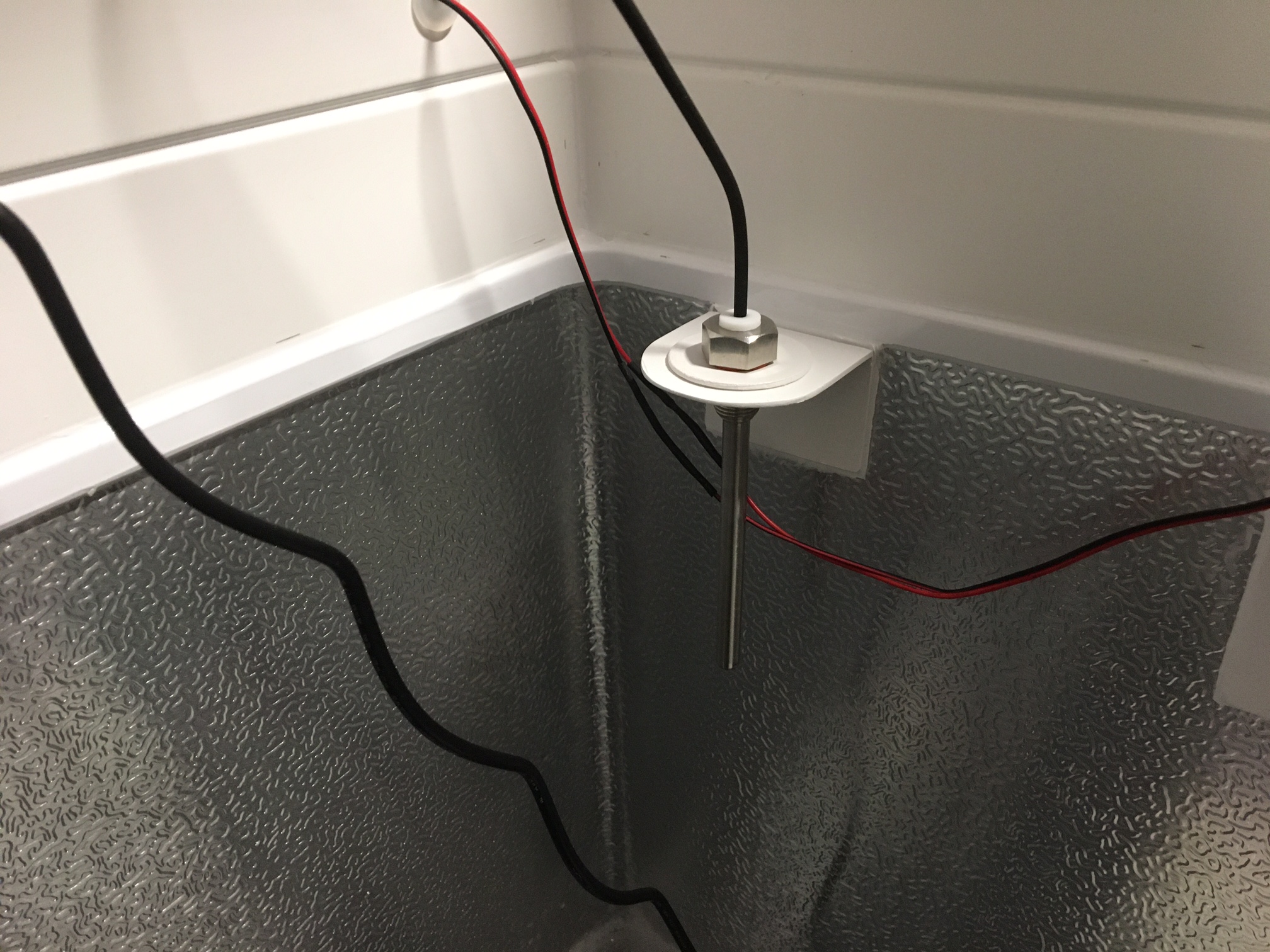

I'm a new brewer, I started at the beginning of the year and have brewed 7 all grain batches. I recently got a really good deal on a chest freezer that someone had already converted into a keezer by putting a steel plate through the front wall with three tap holes. Its 15 years old and was originally white/pretty rusted in some spots so I sanded/repainted it and threaded an Inkbird IT-308 temp controller and fan through an existing hole drilled for the original temp controller. I finally finished recently and moved it to my basement. I bought 3 kegs and plan to have two more inside soon (only 1 in the keezer right now). Its been running for a couple days now and I noticed it seems to cycle too often so I sat and recorded the times: approximately 26 minutes off, 7 minutes on. Maybe this fluctuates but after some research it seems like this is way too often. I saw some people saying the probe needs to be in water and having more kegs inside will help, but that can't be the only reason? It does not seem like there is any cold air escaping from what I can tell and again there is no collar, it has the original gasket. Pictures attached and a few more specs below:

- Basement Temp: Ranges from 60F to 65F

- Temp control setting: 36F, cooling differential 2F. Temp gets down to 34.9F

- Basement Temp: Ranges from 60F to 65F

- Temp control setting: 36F, cooling differential 2F. Temp gets down to 34.9F

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)