30Bones

Well-Known Member

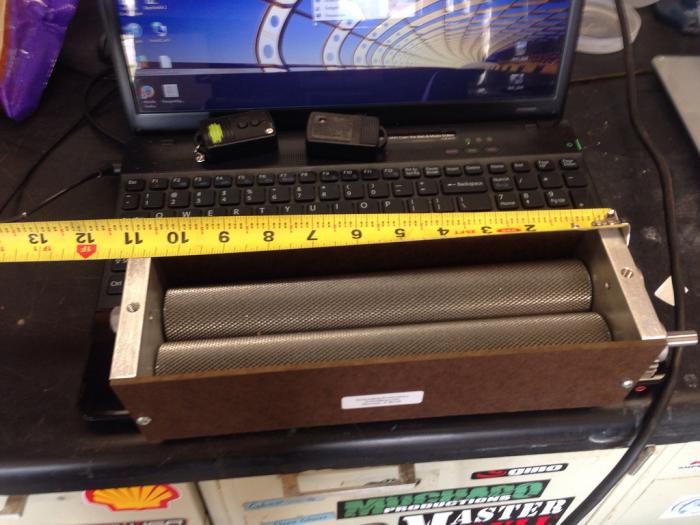

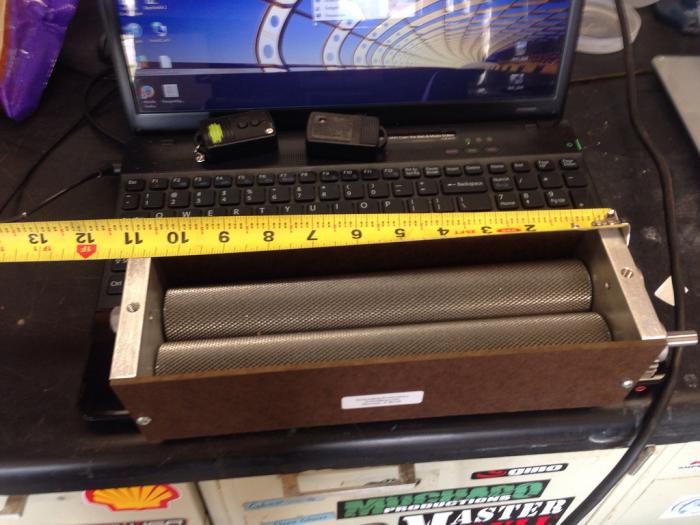

I got my JSP mill Friday and whipped out this simple mount out of some scrap 3/4" plywood. I had my Dad router the edges yesterday to minimize slivers, also rounded off the corners.

I didn't want a dedicated motorized stand and came up with a simple and space saving way to mount this to my brew stand to mill the grains and remove it for storage so it doesn't get burnt during brew days. This thing is massive so I may need to DIY a way to chute the grains to the bucket below.

1/4" x 20 SS bolts were used throughout (may need to upgrade the 2 on the stand, this thing is heavy). I drilled two holes in my stand and hard mounted 2 studs. The hole for the grain is 1.5". The rest is pretty self explanatory.

The hopper is an old 5 gallon bucket with the bottom cut out and riveted to a large funnel I already had. I clamp it to my keggle while in use.

I didn't want a dedicated motorized stand and came up with a simple and space saving way to mount this to my brew stand to mill the grains and remove it for storage so it doesn't get burnt during brew days. This thing is massive so I may need to DIY a way to chute the grains to the bucket below.

1/4" x 20 SS bolts were used throughout (may need to upgrade the 2 on the stand, this thing is heavy). I drilled two holes in my stand and hard mounted 2 studs. The hole for the grain is 1.5". The rest is pretty self explanatory.

The hopper is an old 5 gallon bucket with the bottom cut out and riveted to a large funnel I already had. I clamp it to my keggle while in use.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)