Wow what an update! And congrats on the upcoming "assistant."

Trust me, brew now, while you have the chance. You won't have time, at least in the first 6 months!

Ha ha, thanks man! Just getting started on the clear now!

Wow what an update! And congrats on the upcoming "assistant."

Trust me, brew now, while you have the chance. You won't have time, at least in the first 6 months!

Wow what an update! And congrats on the upcoming "assistant."

Trust me, brew now, while you have the chance. You won't have time, at least in the first 6 months!

Maybe it is just me, but it says the video is private.

Anyway. Awesome build from the pics!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Looks great! You will see your influence in my tasting room when I finally get there in a year or two!

Looking good my friend. Better access to see this now I am home from China. Internet unrestricted

Amazing work/skills. looks more like a Nightclub than a bar.

Rock and Roll !!!!

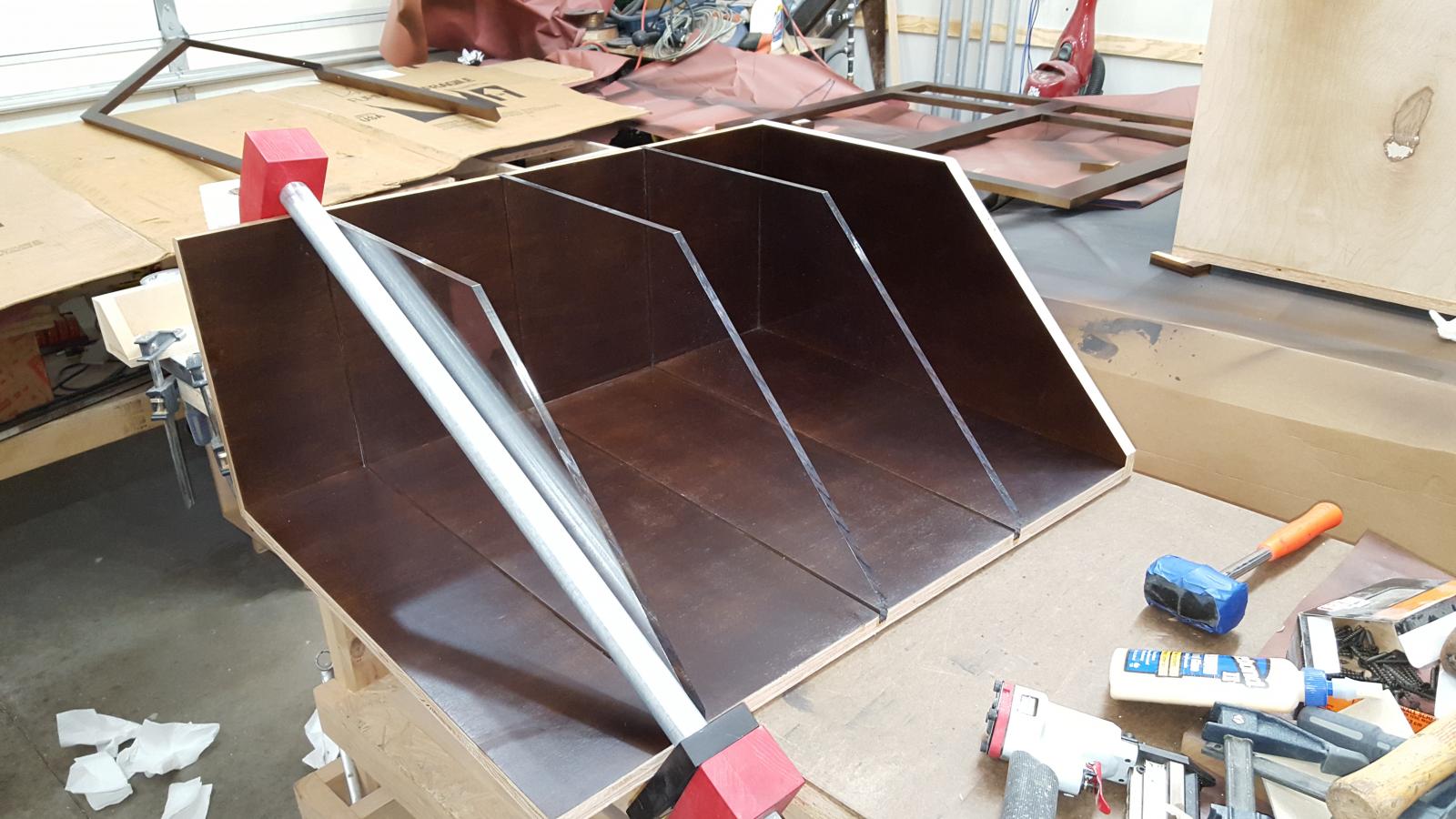

![20151123_121234[1].jpg 20151123_121234[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270803-20151123-121234-1-.jpg)

![20151123_121244[1].jpg 20151123_121244[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270804-20151123-121244-1-.jpg)

![20151123_123648[1].jpg 20151123_123648[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270805-20151123-123648-1-.jpg)

![20151123_123655[1].jpg 20151123_123655[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270806-20151123-123655-1-.jpg)

![20151123_133937[1].jpg 20151123_133937[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270807-20151123-133937-1-.jpg)

![20151123_133945[1].jpg 20151123_133945[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270808-20151123-133945-1-.jpg)

![20151123_134135[1].jpg 20151123_134135[1].jpg](https://cdn.homebrewtalk.com/data/attach/270/270809-20151123-134135-1-.jpg)

Looking great, man! I hate making doors, myself, but in the end they are worth the effort.

Hi, my name is Evan, and I have a problem... I'm addicted to table saws. Lol. It's so funny, I now own six, no check that, number seven is in the back of the truck right now. Lol, I think I need counseling... My wife thinks I've lost it!

Please send all excess table saws I my direction. I will take extremely good care of them for you

Looking Great my friend

Please send all excess table saws I my direction. I will take extremely good care of them for you

Looking Great my friend

Ouch . . .

Lol Paul, I actually love restoring these old 113 and 315 Craftsman saws. People like to make fun because they see my shop full of "Junk" tools because they are not Unisaws or Powermatic, but the joke is on them. I have every one of my saws tuned to less then 0.002" runout. I can take a Craigslist $50 113 and make it run like a $1,000.00 cabinet saw. I have developed many parts and gizmos over the years, hell even the paint codes, for these saws. New bearings, balanced arbors, turned balanced pulleys, PALS set ups (build myself) better fences etc.

Regaurdless, if you have 1 $3,500 saw or not, it still becomes a multi purpose tool. You make rip cuts, and cross cuts and angle cuts and 45deg cuts and each time you move the blade, you take the accuacy out of the tool. Yes yes one high end cabinet saw will be better then one old contractor saw, but it pales in comparison to many dedicated setup saws.

For instance my main saw at the house is a 1985 113 with a 60" digital fence on it. I do most of my work on it. But I have a saw that is set at a perfect 45deg and it took maybe 3 hours to get it that way. But it NEVER is adjusted, so it will always be that way. It doesn't even have a handle on the trunion side. So if the wife wants a quick picture frame, I literally can turn one out including finish and the glass in a half hour.

I have one set to a perfect undersized 3/4 cab ply dado with a 24" sled on it, I don't use it for anything but that. But this new one will be the new dedicated crosscut saw running a Freud 1080X. It will have both a 50" sled and a 25" sled. This will replace my sliding miter and I am guaranteed perfect 90-90 cuts every time.

All in all I have 7 saws (Two just went to My brothers for use) and have less than $1,000 in them. Hell I have way more than that in good Freud Blades.