Well, I have been absent for some time from HBT. I'm a every-few-night grazer, but barely. I haven't contributed much for the last year, and I've been overwhelmed with the emails asking how I was. This place really is a great community, and you all are great people. So the reason I have been so busy is Multi-fold. For starters I spent this summer at my field certification camp in the middle of Wyoming. Fun time but was so glad to get home, and back to brewing! The other, was the wonderful lady who has so graciously allowed me to call her my girlfriend accepted a better offer in October. She said yes to a very long rehearsed proposal from yours truly! :rockin: So as you can imagine, life has been a little hectic around here.

So, after moving her in back in June, and planning a wedding and getting through the holidays, it's time to build the bar I set out to build when I bought the house literally a month before I met her. So now my, strike that, OUR new bar is coming to fruition very soon. It's wont be a particularly fast event, cause I still have classes and more wedding planning to do, but very soon we will be at our new bar.

at our new bar.

So we are starting with a roughly 600 square foot room, longer than wide with 4 doors. There is a nice little set back by the closet that works well. We have had a temporary bar set up there to test out the flow of the room and what not. So it's about to come down, and the building will begin.

I have a full cabinet shop, although a very tiny one, so I will be building all of the woodwork myself. I'm torn about what species I will use. Right now it's either Hard Rock maple or Cherry. I have a nice stock of Cherry, but think I might be favoring the maple at this point.

I have a full machine shop as well, so I will be building everything I can there as well. I will be making my own manifolds for sure

The bar will have a keezer built in as best I can to make it look fitting. It will house 5-7 kegs and a number other pressure vessels made from 2 liter bottles which I will talk about at a future time.

The bar will also have a full 12 button bar gun with a custom set up for the syrups.

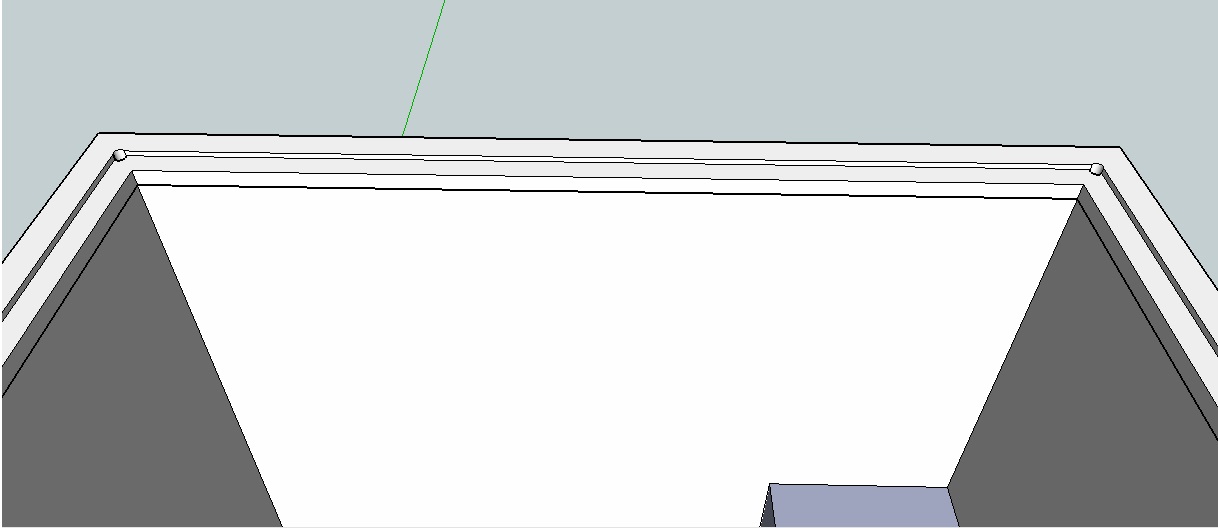

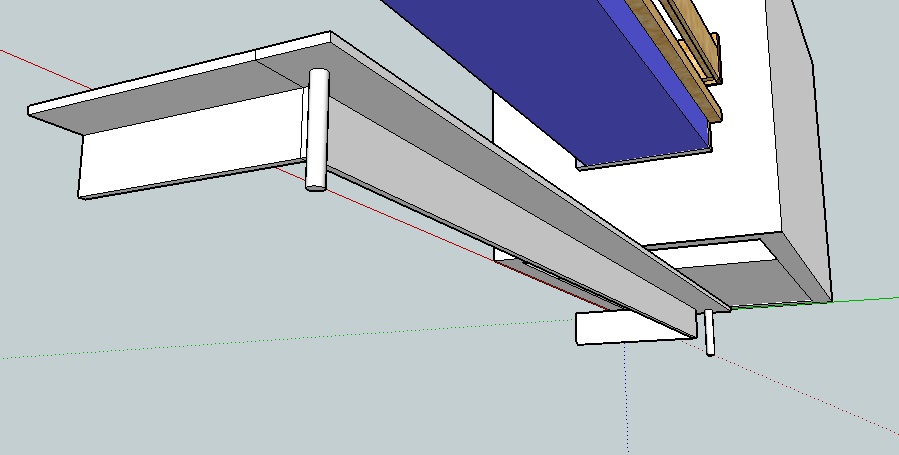

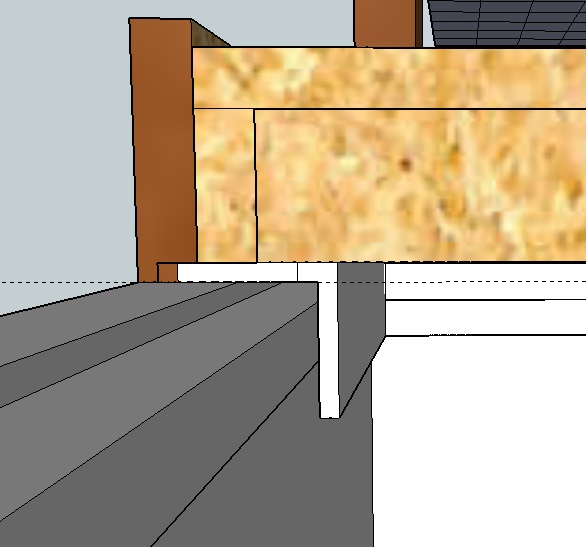

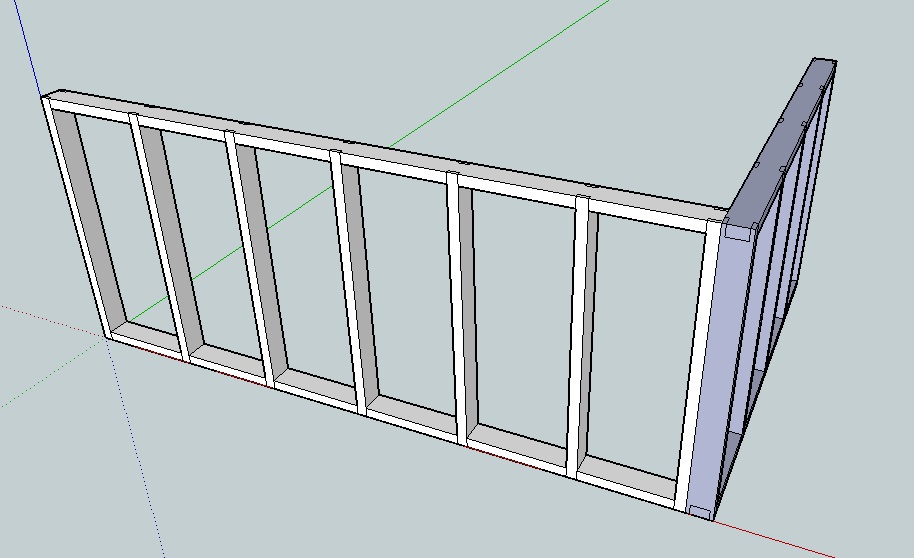

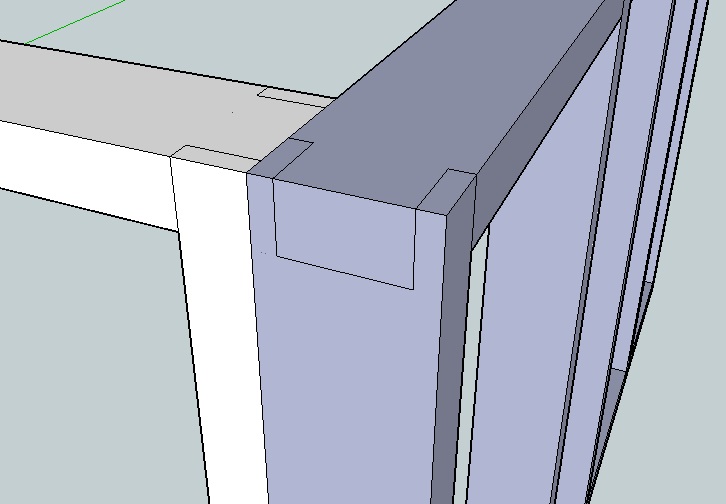

I have drawn up a 3D rendering of it. Here's a few shots of it.

HAPPY NEW YEAR!

So, after moving her in back in June, and planning a wedding and getting through the holidays, it's time to build the bar I set out to build when I bought the house literally a month before I met her. So now my, strike that, OUR new bar is coming to fruition very soon. It's wont be a particularly fast event, cause I still have classes and more wedding planning to do, but very soon we will be

at our new bar.

at our new bar. So we are starting with a roughly 600 square foot room, longer than wide with 4 doors. There is a nice little set back by the closet that works well. We have had a temporary bar set up there to test out the flow of the room and what not. So it's about to come down, and the building will begin.

I have a full cabinet shop, although a very tiny one, so I will be building all of the woodwork myself. I'm torn about what species I will use. Right now it's either Hard Rock maple or Cherry. I have a nice stock of Cherry, but think I might be favoring the maple at this point.

I have a full machine shop as well, so I will be building everything I can there as well. I will be making my own manifolds for sure

The bar will have a keezer built in as best I can to make it look fitting. It will house 5-7 kegs and a number other pressure vessels made from 2 liter bottles which I will talk about at a future time.

The bar will also have a full 12 button bar gun with a custom set up for the syrups.

I have drawn up a 3D rendering of it. Here's a few shots of it.

HAPPY NEW YEAR!