LumberZach

Well-Known Member

I had my first Tree House back in early 2015 when they were still brewing out of Monson. Their flagships (Green, Julius, and Haze) were quite a bit better than they are now.

Last edited:

Clove comes from ferulic acid so perhaps that why tree house doesnt use any wheat? Try to prevent clove from t58. I also read ferment temps matter but I dont remember at what temp t58 seems to produce most clove. I think it was lower temps

Seems like the beer is much more hazy now. I had it at Monson in 2016 and it was amazing. Had that amazing melon ester. So whatever they were doing back then, they are doing now. But if you look at older pics of their beer, some are clear looking. I also think they are doing something with another yeast for the natural carbonation. Krausening of some sort and or blending. What’s the fastest way to naturally carbonate? I’ve also seen pics in Monson of them using a hop canon so they must use that to dry hop. Can you krausen/dry hop with one of those?I had my first Tree House back in early 2015 when they were still brewing out of Monson. Their flagships (Green, Julius, and Haze) were quite a bit better than they are now.

Strange I cant open the link but I read the opposite.Ferulic acid comes more from barley than from wheat though.

https://braumagazin.de/article/brewing-bavarian-weissbier-all-you-ever-wanted-to-know/

I like the way you are thinking.@MrPowers I feel your pain brotha, I’m in PA and finding TH is always difficult.. maybe some folks should be sending us cans for charity

I’ve said it before and will continue to do so — TH is a modern style blending and krausening experiment — There is no other way you will achieve their mouthfeel and complexity, sometimes opposing bready and fruity characteristics with a unidimensional/unidirectional process, otherwise everyone else will be brewing beers like them. How Firestone Walker produce such amazing barrel aged stouts? ever wondered why all top rated beers in the world are mostly barrel aged stouts?, how New Belgium, Oskar Blues and even Dogfish Head keep consistency of their flagships?, How Big Beer, and some Large Craft control their quality and yet keeping simple processes and achieve their consistency day in and day out?. Blending is still in its modern infancy despite being such an old technique and unfortunately most people see it as a means of correcting flaws or for open fermented or barrel based styles but there is much more to it, and it’s all around us. All the best breweries in the world achieve their complexity and yet simplicity through blending synergy and TH is no exception, they just found a way to do it with a modern style of beer and while everyone else keeps brewing unidimensionally they’ll always be at the top.

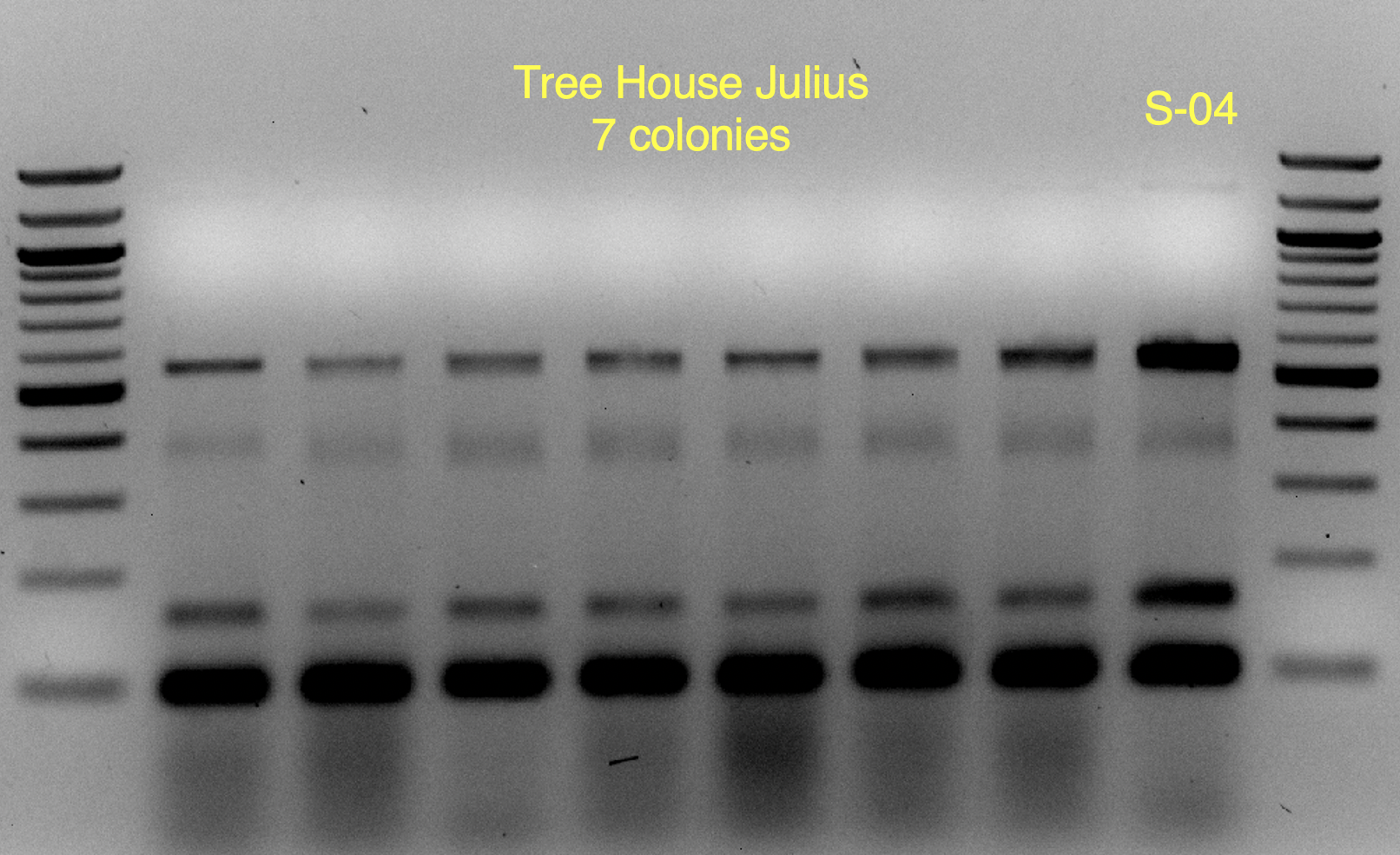

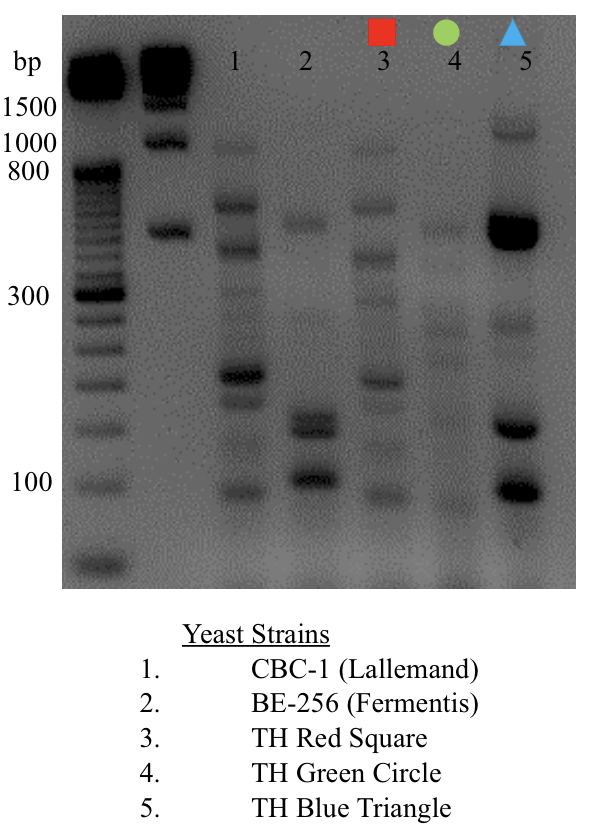

With all the evidence we’ve found all these years, there is no question their beers have multiple yeasts phenotypes and yet their final product is a perfect balance of each one’s properties. Malt wise, we know they use different malts that may not even make sense putting all in one wort without being too complex — the list goes on. The biggest complain of all clone attempts is the phenolic spice train wreck caused by the POF+. Independent of which permutation you pursue, when you co-pitch yeasts of different styles unidimensionally (1 wort) you lose control and it’s all for grabs... yeast decide for you that day, will you take that risk with a multimillion dollar facility?? you can have luck for a couple days just to see your brew go south, complains keep going on and on. Fermenting separately allow the yeasts to run their course on their own direction, but yet you are still in control of the final product and yet simple enough you can achieve with 1 mash tun, 1 kettle and 2 fermentation vessels. Want to get rid of the phenolic wreck? ferment a German weiss separately, crash the yeast at almost 0C as you see in the controller pics, and blend into the already fermented S04 blonde followed with the pale ale krausening addition (or wathever other combination).. this type of approach gives you control... maybe why T-58 barely shows on the final product?, I can keep going on and on...

I don’t want people to think this is the exact solution but we need to start getting out of our comfort zone if we want to get to the bottom of this, and by leveraging simple processes where we can achieve a product aligned with the evidence we know so far, and that only can be done as a team effort.

For the sci-fi geeks, some fun quote from S.R Hadden and totally applicable here LOL - “pages and pages of data, over 63,000 and all, and on the perimeter of each... they do, if you think like a Vega’n.. an alien intelligence got to be more advanced, that means efficiency and functioning at multiple levels, and, in multiple dimensions..”

Cheers!

https://www.gearpatrol.com/food/drinks/a462014/how-brewers-use-beer-blending-techniques/

https://www.homebrewcon.org/wp-content/uploads/presentations/2007/MBPresentation.pdf

https://www.google.com/amp/s/beerandbrewing.com/amp/when-to-blend-your-beer/

https://www.homebrewersassociation.org/how-to-brew/the-art-of-blending-beer/

IF they’re blending, can we assume that the amount of yeast being found in all of the analyses being done in this thread is similar to the blending ratios? Forgive me if this is a silly question as I recognize many of the posters here have far more knowledge than I.

I guess what I’m asking is would the final blended beer be about 90+% S-04 fermented beer, ~ 3% wb-06 fermented beer, and ~ 3% t-58 fermented beer?

Not necessarily. Different yeasts will flocculate better than others, for example T-58, and S-04 will settle out more than wb-06 would. So you would get more wb-06 in an equal blend of the three. That would also depend on if the batches are filtered before blending. If @Clyde McCoy is seeing more S-04 in the can that the other two yeasts it could also mean that it is used for kräusen or some other late addition like packaging. It could also explain why T-58 could have taken over in the older can of very green, or it could be that that particular blend of very green was made with the bottom of the T-58 batch.

I'm still not convinced that they were blending the separately fermented batches back in their Brimfield brewery or even today. I guess its possible as I remember seeing kegs filled directly from their bright tank and thinking that the bright tank was rather large comped to the rest of their brewing equipment, so they could have just done the blending in the bright tank. I still think introducing a separate yeast during kräusen is more likely than a blend.

Are the tests you’re doing 100% accurate? Don’t some yeast look similar if not exactly like each other with their banding? Not trying to be a negative nance but I remember that in some past trials. I think everyone interested in this thread just needs to start experimenting to see for themselves. A lot of us on here in the past have tried those yeast at different pitching rates, temps, together/not together and no one has hit the nail on the head, yet. Yeah maybe some have gotten “close” with those yeasts pitched dry with no o2 but I beg to differ. Everyone at least has had a hint of clove and no TH beer ever has that. I’m very sensitive to it. What about WLP028 Scottish yeast? They mention melon esters in the description. I’m gonna give that a try. All I know is I get a lot of Isoamyl acetate in their house yeast beers. We should explore the yeast that produce that the most and how to accentuate it. Brew on!I don't think they're blending batches. My best guess at this time is co-pitch with a very small amount (under 5% combined, possibly even less) of T-58 and WB-06 with S-04. The detected ratios will change depending on the age of the can at the time of analysis.

Are the tests you’re doing 100% accurate? Don’t some yeast look similar if not exactly like each other with their banding? Not trying to be a negative nance but I remember that in some past trials. I think everyone interested in this thread just needs to start experimenting to see for themselves. A lot of us on here in the past have tried those yeast at different pitching rates, temps, together/not together and no one has hit the nail on the head, yet. Yeah maybe some have gotten “close” with those yeasts pitched dry with no o2 but I beg to differ. Everyone at least has had a hint of clove and no TH beer ever has that. I’m very sensitive to it. What about WLP028 Scottish yeast? They mention melon esters in the description. I’m gonna give that a try. All I know is I get a lot of Isoamyl acetate in their house yeast beers. We should explore the yeast that produce that the most and how to accentuate it. Brew on!

i use to think that as well, but after snooping around I found a description from them of one of their core beers, I want to say doppelgänger or doubleganger, that says it was made with water, yeast, hops, and barley, or something to that extent. Can’t remember if it was on their site or Twitter.Any chance that...Gasp, wait for it, they have some sort of amazing melon/bubblegum extract flavoring agent that they use? I know it’s sac religious to think such preposterous things, but all evidence points to an overwhelming amount of S-04, which is really not that exciting of a yeast. The flavoring industry is absolutely massive and if you know what you’re doing you can have certain flavors developed for you.

I’m sure the chance of this is slim to none, but it’s crossed my mind a few times since I started reading this thread.

Yeah, while I don’t really think they’re using some kind of proprietary/custom flavoring agent, I wouldn’t necessarily rule it out either. But the fact that they said one of their beers was made with water, yeast, hops and barley, or whatever, doesn’t surprise me or mean anything. Think about it..,if you were them would you say doppelgänger is made with water, yeast, hops, barley, AND our top secret, never spoken of, custom flavoring agent that sets us apart from every other brewery in the world, creates demand like no other, and has home brewers and professional brewers all over the world obsessing over unlocking our magic yeast secret, that wink wink, they never will. I’m pretty sure you wouldn’t.i use to think that as well, but after snooping around I found a description from them of one of their core beers, I want to say doppelgänger or doubleganger, that says it was made with water, yeast, hops, and barley, or something to that extent. Can’t remember if it was on their site or Twitter.

Isoamyl acetateYeah, while I don’t really think they’re using some kind of proprietary/custom flavoring agent, I wouldn’t necessarily rule it out either. But the fact that they said one of their beers was made with water, yeast, hops and barley, or whatever, doesn’t surprise me or mean anything. Think about it..,if you were them would you say doppelgänger is made with water, yeast, hops, barley, AND our top secret, never spoken of, custom flavoring agent that sets us apart from every other brewery in the world, creates demand like no other, and has home brewers and professional brewers all over the world obsessing over unlocking our magic yeast secret, that wink wink, they never will. I’m pretty sure you wouldn’t.

Again, I don’t really think this is what they’re doing, but I also don’t think it’s all that far fetched.

Escarpment did a webinar series on yeast and in it they talked about how acetate esters are very hard to modify. They are still not well understood and FAN plays a role. Not much research has been done yet on ale yeasts.Isoamyl acetate

Good points! I think I follow you on insta, your stuff looks good. I personally agree that they are probably blending batches/kausening- I hit on it in my older posts. I got the flavor pretty close from my own experiments - still have some kinks to work out but I’m pretty close to there.

Just one thing to touch on - krausening doesn’t get rid of phenolic wrecks! I recently did an all Galaxy TIPA with mostly T-58 and a touch of Wb-06 and it was a nightmare - huge clove bomb. I did 3 separate spiesse with dry hops and 3 separate English yeasts (LAIII, S33, & 007) with my hop cannon - nothing fixed it - it was just a little less clovey and insanely bitter. My fix for it was brewing a 5% mosaic and Citra pale ale and blending the two (25% of the clove bomb) with f2 for carbonation. The mouthfeel was unbelievable and I was happy with the results.

I don’t think yeast blends at pitching are bad at this style either. The Farmhouse NEIPA blend from Omega is probably the best I’ve ever used and I saved it for 5-6 generations.

@echoALEia Thanks for the compliments!, do you have another insta tag? I haven’t been very active recently (posting wise) and after looking I can’t find you under your tag here.

Totally agreed with Krausening. Krausening is not intended to fix flaws, its an old but yet still modern enough brewing technique used by German brewers to condition and carbonate lager beers following long lagering periods (yeast died or went dormant) and since they could not use sugar due to their purity law a.k.a Reinheitsgebot which can be easier pronounced as “Reggae-insta-ballz” LOL the way to carbonate was by adding to the ‘already fermented’ beer a small fermenting batch of the same beer (at highest krausen) to condition the beer right before and/or during packaging. One thing they found was that Krausening also benefited the beer by softening the edges, giving the new yeast an additional chance to clean up and smooth things out. Speise technique is similar but not exactly the same, and it’s when you add a small fraction of unfermented wort to an already fermented (but w/ viable yeast) or an ‘almost done’ fermenting beer so it had additional “food” (Speise means ‘food’ in German?) to condition during packaging. None of these techniques were intended to fix flaws but could be applied indirectly to dilute a significantly flawed beer.

What I was referring to the phenol wreck, with the assumption we were blending, when your POF+ batch is fermented you can crash it to eliminate or significantly reduce yeast presence before blending it to the base batch and therefore most likely minimize further phenol development. Also adding a final krausening batch w/ neutral CBC-1/F2 can also help by inhibiting any remaining POF+ yeast from developing over time during final conditioning.

@HopsAreGood thats a great assumption, as @mcoman mentioned, yeasts have different behaviors and properties that are independent of the batch volume - however the final proportions of yeast in the cans hints about their process (and ingredients too). @Clyde McCoy results at high level show they are comfortable with (their process does not remove) S04 from their final product but not with the others, which is obvious since their phenotypes will have a huge impact in their final product quality. The evidence also show they are not filtering - otherwise the data we’ve been collecting means their batches are contaminated with the same strains over and over again or that Fermentis is making the same exact mistakes during yeast manufacturing which both are improbable.

What I would argue and here’s where I need everyone’s thoughts - if we assume they pitch a blend of yeasts into one wort (at any ratio) - then whatever yeast control methods they apply, with the assumption they crash — obviously to control the POF+ — it will have an impact on all the yeast strains in the mix. We know S04 is highly flocculating and therefore (excluding WB-06 which we barely see?) we will end with equal or similar yeast proportions suspended in the beer before krausening. As we all agree they krausen, due to mouthfeel and other sensory, therefore adding the krausen portion will trigger growth of all yeasts at equal or very similar proportions (or even more of POF+ due to its low flocculation) and therefore we will see that in their cans which we don’t. If we all agree, then this idea supports the blending theory - or brewing separately controlled batches that when finally blended may result in unequal populations of yeast in the final product w/S04 leading amounts.

The other option I could use to counter argue myself - with the assumption of one wort-multiple yeasts - unequal proportions of yeast in final product can result if they pitch the POF+ first and then at a certain gravity they add the conditioning inhibitor CBC-1/F2 and then crash both of them, then add S04 to finish what’s left and then krausen with an S04 fermenting batch. This option will finish with unequal populations and can explain why CBC-1/F2 shows minimally in their final product. One disadvantage of this is the product consistency risk as every second and temperature counts and the slightest mistake controlling the POF+ will screw the batch - a risk I will never take at such high batch volumes. Blending is less risk as you control each step and know the quality of the parts before committing to the final product.

Cheers!

https://www.anchorbrewing.com/blog/anchor-terminology-krausening/

I’d be very surprised if they’re pitching all three yeasts at the same time, unless maybe they’re using something we haven’t uncovered, such as a wine yeast. If it was that simple someone would’ve figured it out by now, and TH (core beers) has a very distinct flavor that I’ve never gotten from anyone else.

The wine yeast that is potentially in question is not a killer strain so it could be copitched.

Its also POF-

Not sure how T-58 comes into the equation honestly. Might be just added to “protect” whatever it is they use to primary ferment.

From the little we know about their process and much experienced via sensory, their process is simple (or they try to keep it as simple) and has a high batch-to-batch reproducibility. Not an expert on this subject but I really doubt any wine yeast is involved here for many reasons 1) everything we’ve tested seem to match beer yeasts (anyone correct me if I’m wrong)

Isomerisation's original PCRs had a mystery strain that was guessed to be CBC-1 or F2, which are wine yeasts used for bottle/cask conditioning, but we didn't really have any wine fingerprints in the library to know whether it was even a wine yeast at that time.

2) wine yeasts are best in tannin environments which I believe is not the case here

I'm not sure what you mean by "best" in this context. But tannins are just the old name for polyphenols, which "hazy hops" have in abundance.

3) some or most? wine yeasts are inhibiting to other yeasts

Most, not all. A lot of the Uvaferms and Enoferms are non-killer for instance. But as with the discussions towards the start of this thread about CBC-1/F2, even a killer yeast needn't necessarily be incompatible with some processes - and would be a good reason to blend beers rather than yeasts.

4) most? wine yeasts do not metabolize maltotriose or other malt sugars which could be a problem to a brewer seeking simplicity

Not really relevant if you're just using it as a "helper" yeast to add flavour, as eg Scott Janish did with VIN7 to increase 3MH/3MHA. People are now using non-Saccharomyces species like Metschnikowia which only attenuate to 20-30%, as helper yeasts for flavour.

5) too much monitoring and chemistry tests involved during fermentation with wine yeasts?

??? No different to beer yeasts. You think wine yeasts are some weird separate thing, whereas they're not much different to something like Belle Saison - very consistent, reliable dry yeast.

6) just simply don’t seem to fit the drinkability of their beers w/o too much process complications

??? I'm not sure what this even means.

I’m not a wine maker but from my impression, fermentation with wine yeasts requires more attention (YAN, FAN, PAN, BAM!) to keep the yeasts doing what they are supposed to. Not sure if that’s due to grape juice not been nutritious enough

Yes, it's everything to do with the liquid they're fermenting, and not much to do with the yeast themselves. Beer is made from seeds, which have all the nutrients needed to make a new barley plant; wine is made from fruit juice, which is just meant to attract animals to eat the fruit to disperse the seeds so is just flavoured sugar water. But even so, the best beer producers add nutrients (follow the link to the recipe spreadsheet), it's not complicated but it does reward experimentation for the best results.

I also do not know how pure some wine yeast cultures are to this date,

Probably purer than some dry beer yeasts...

Funnily enough we've just been talking about wine yeasts in beer over on another thread. But all this talk of krausen and speise is typical of the US obsession with German brewing, which overcomplicates things to fit in with the myth of the Reinheitsgebot. It ignores the fact that US craft brewing owes far more to a different beer culture, one that prizes soft drinkability above anything else, one that gave Conan and 1318 to the US and positively worships the complexity of multi-strain yeasts rather than thinking they're an abomination to be rooted out.

Another clue - we talk about New England IPA and not New England bocks.

Yes, you need to switch your frame of reference from Germany to British brewing practices.

Forget krausening, I'd suggest the way to look at these beers are as low-oxygen cask-conditioned beers that generally follow British practice but excluding oxygen as much as possible. So any conditioning is done with sugar rather than introducing a complex mix of contaminants in the form of krausen. Most North Americans craft beer lovers don't understand what cask ale is all about as it's too crafty for them, but some are pleasantly surprised by how good cask-conditioned hazy beer can be. So it's no surprise that maybe some brewers are using British techniques and it baffles people who don't get the references.

From the little we know about their process and much experienced via sensory, their process is simple (or they try to keep it as simple) and has a high batch-to-batch reproducibility. Not an expert on this subject but I really doubt any wine yeast is involved here for many reasons 1) everything we’ve tested seem to match beer yeasts (anyone correct me if I’m wrong)

Isomerisation's original PCRs had a mystery strain that was guessed to be CBC-1 or F2, which are wine yeasts used for bottle/cask conditioning, but we didn't really have any wine fingerprints in the library to know whether it was even a wine yeast at that time.

2) wine yeasts are best in tannin environments which I believe is not the case here

I'm not sure what you mean by "best" in this context. But tannins are just the old name for polyphenols, which "hazy hops" have in abundance.

3) some or most? wine yeasts are inhibiting to other yeasts

Most, not all. A lot of the Uvaferms and Enoferms are non-killer for instance. But as with the discussions towards the start of this thread about CBC-1/F2, even a killer yeast needn't necessarily be incompatible with some processes - and would be a good reason to blend beers rather than yeasts.

4) most? wine yeasts do not metabolize maltotriose or other malt sugars which could be a problem to a brewer seeking simplicity

Not really relevant if you're just using it as a "helper" yeast to add flavour, as eg Scott Janish did with VIN7 to increase 3MH/3MHA. People are now using non-Saccharomyces species like Metschnikowia which only attenuate to 20-30%, as helper yeasts for flavour.

5) too much monitoring and chemistry tests involved during fermentation with wine yeasts?

??? No different to beer yeasts. You think wine yeasts are some weird separate thing, whereas they're not much different to something like Belle Saison - very consistent, reliable dry yeast.

6) just simply don’t seem to fit the drinkability of their beers w/o too much process complications

??? I'm not sure what this even means.

I’m not a wine maker but from my impression, fermentation with wine yeasts requires more attention (YAN, FAN, PAN, BAM!) to keep the yeasts doing what they are supposed to. Not sure if that’s due to grape juice not been nutritious enough

Yes, it's everything to do with the liquid they're fermenting, and not much to do with the yeast themselves. Beer is made from seeds, which have all the nutrients needed to make a new barley plant; wine is made from fruit juice, which is just meant to attract animals to eat the fruit to disperse the seeds so is just flavoured sugar water. But even so, the best beer producers add nutrients (follow the link to the recipe spreadsheet), it's not complicated but it does reward experimentation for the best results.

I also do not know how pure some wine yeast cultures are to this date,

Probably purer than some dry beer yeasts...

Funnily enough we've just been talking about wine yeasts in beer over on another thread. But all this talk of krausen and speise is typical of the US obsession with German brewing, which overcomplicates things to fit in with the myth of the Reinheitsgebot. It ignores the fact that US craft brewing owes far more to a different beer culture, one that prizes soft drinkability above anything else, one that gave Conan and 1318 to the US and positively worships the complexity of multi-strain yeasts rather than thinking they're an abomination to be rooted out.

Another clue - we talk about New England IPA and not New England bocks.

Yes, you need to switch your frame of reference from Germany to British brewing practices.

Forget krausening, I'd suggest the way to look at these beers are as low-oxygen cask-conditioned beers that generally follow British practice but excluding oxygen as much as possible. So any conditioning is done with sugar rather than introducing a complex mix of contaminants in the form of krausen. Most North Americans craft beer lovers don't understand what cask ale is all about as it's too crafty for them, but some are pleasantly surprised by how good cask-conditioned hazy beer can be. So it's no surprise that maybe some brewers are using British techniques and it baffles people who don't get the references.

@Northern_Brewer show is the British way with wine strains!

Agreed on CBC-1 my friend, if you look at all my posts I have never questioned presence this yeast as I thought it was confirmed via post #159 - I’ve been thinking of it as a beer strain and completely forgot this yeast properties suggests it derived from a wine strain at some point — but as you should know by now, talking about it in the flavor context is a waste of time as this yeast is completely neutral in flavor and aroma and thus doesn’t contribute to the beer flavor complexity. What this tells me is that the presence of this yeast is there simply as a result of their process to either inhibit other yeasts and/or condition, not to produce flavors.

How and at what temps do you condition? Do you use a spunding valve to keep the pressure in check?I have been using CBC1 to naturally carbonate all of my APA/IPA’s for the last year or so. It doesn’t add anything perceptible in the form of flavor or esters. It allows the base yeast character to remain intact. It also doesn’t add much from a bio-transformation perspective (I fermenter prime/add CBC after dry hopping).

What it DOES add is an incredible mouthfeel that is very soft and full bodied. Even in the absence of adjuncts or high chloride levels. You can push sulfate to 300-400ppm and still get a soft/rounded beer with great aromatics. My last NEIPA was a perfect example of that. It was a Pearl single malt + dextrose with approx 350ppm sulfate that was incredibly soft. CBC is also VERY resistant to hop creep/diacetyl. Which makes it a truly awesome conditioning strain for these beers.