12/17/2015 update

after six agonizing weeks, my first 'real' piece of brewing equipment showed up today: one of the new spike v3 kettles! specifically, my hlt. i did a custom order with them to get the necessary fittings welded on. wow, this thing is incredible. it doesn't make the beer taste any better but the spike packaging is a nice touch:

opening the box, it is well packaged. not the double-walled sides on the shipping box, with air gap between:

pulling out the tube from the lower left, which i can only assume is the sight glass:

i'm a genius!:

it comes with a brush for cleaning which is alas, too short to clean the glass from one end. no worries, it is long enough to reach over halfway down the tube, to allow cleaning from both ends:

it also comes with an engraved heat shield for the sight glass. this is an electric build so i don't need it but a nice touch with the engraving. no photo but it comes in a ziploc bag:

the assembly comes apart at both ends. it is a friction fit where the glass connects to the fitting:

the lid comes wrapped in plastic:

the handle is seamlessly attached, only some slight buffing on the backside of the lid. the grip is solid and comfortable:

another box inside the kettle, well wrapped:

and well packed:

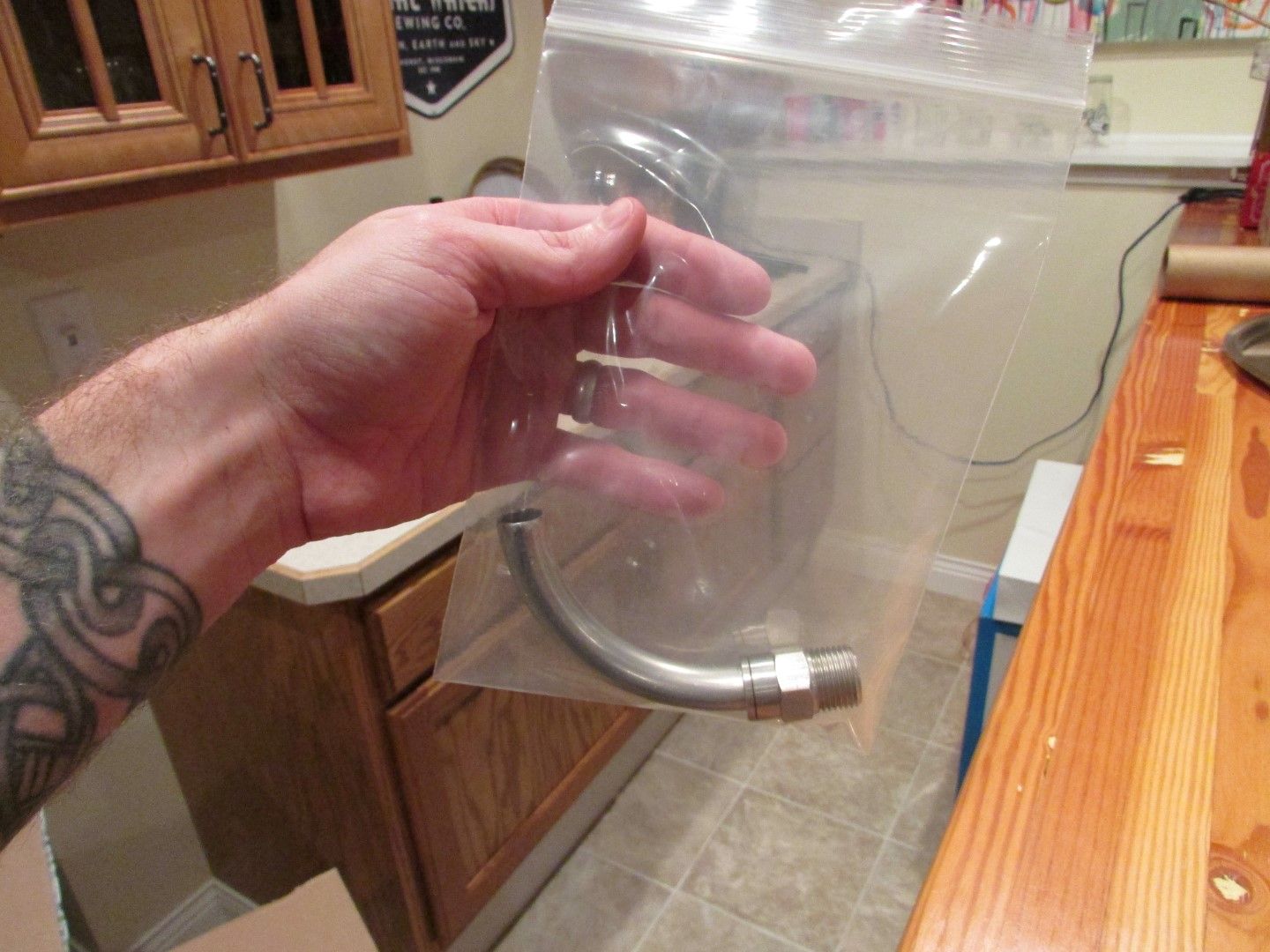

inside is the dip tube, wrapped in a ziploc bag:

as i understand this is not their standard dip tube. spike had a boo-boo on the elevation for my discharge fitting but offered up a custom dip tube at no charge. a little rough on the intake excellent customer service!:

there is a threaded connection to the kettle but a friction fit for the tube, very easy to remove:

kettle removed to show the thick foam at the bottom of the shipping box. the cardboard is a bit beat up but the double-walled box makes for no shipping damage:

and here she is, in all her plastic-wrapped glory. the weight is incredible, very well constructed:

appears to be a custom tag, not sure if this ships on standard orders. this number was also on the shipping box:

gigantic tattoo:

discharge fitting. beautiful welding, fitting is square and level to the kettle:

2" tri-clamp fitting for my heating element. i will be going with ripple elements and it will be easier to snake into the kettle with a 2" connection vs. a 1.5":

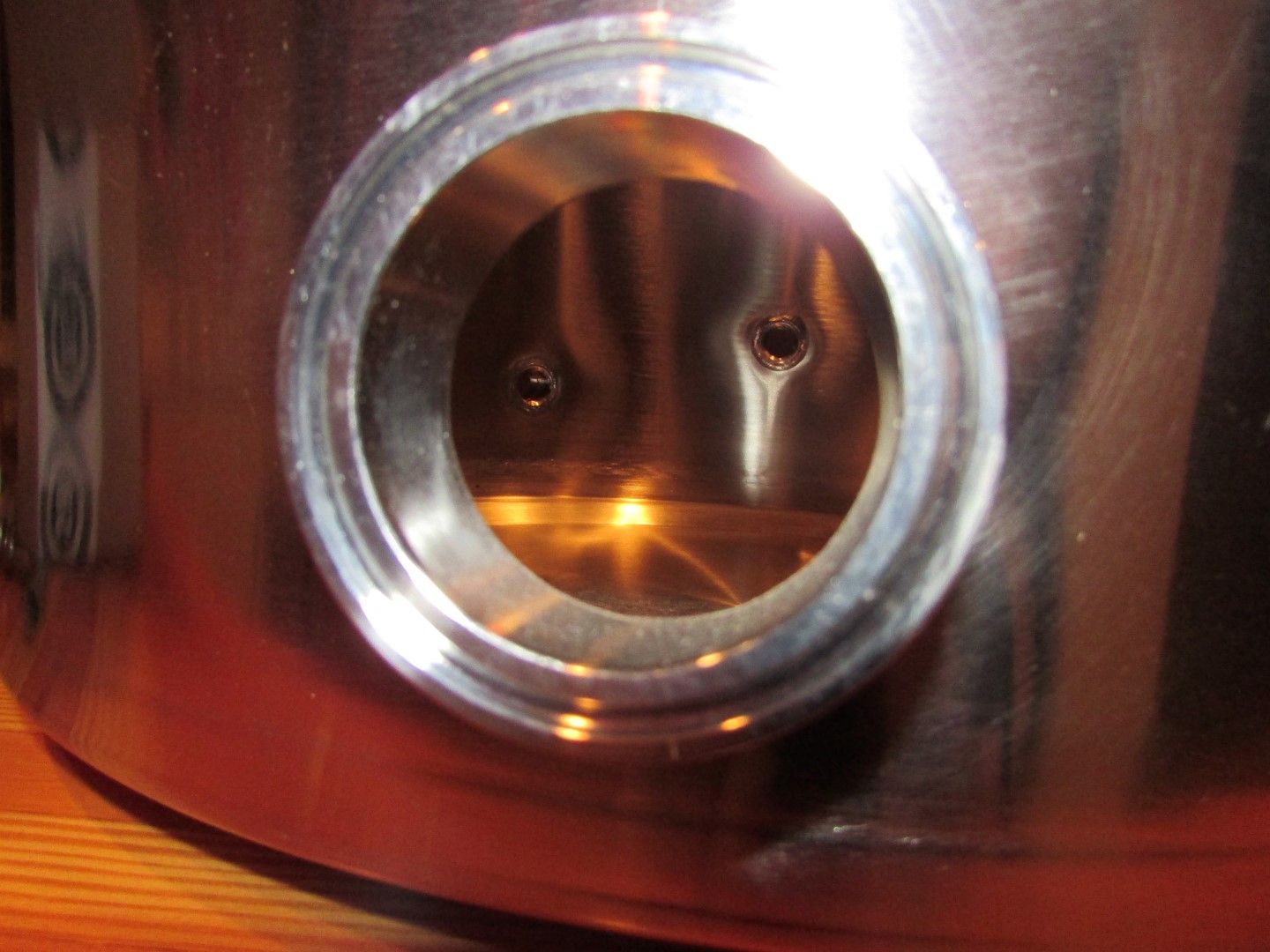

looking through the connection, with the discharge and bottom herms coil fittings on the opposite side:

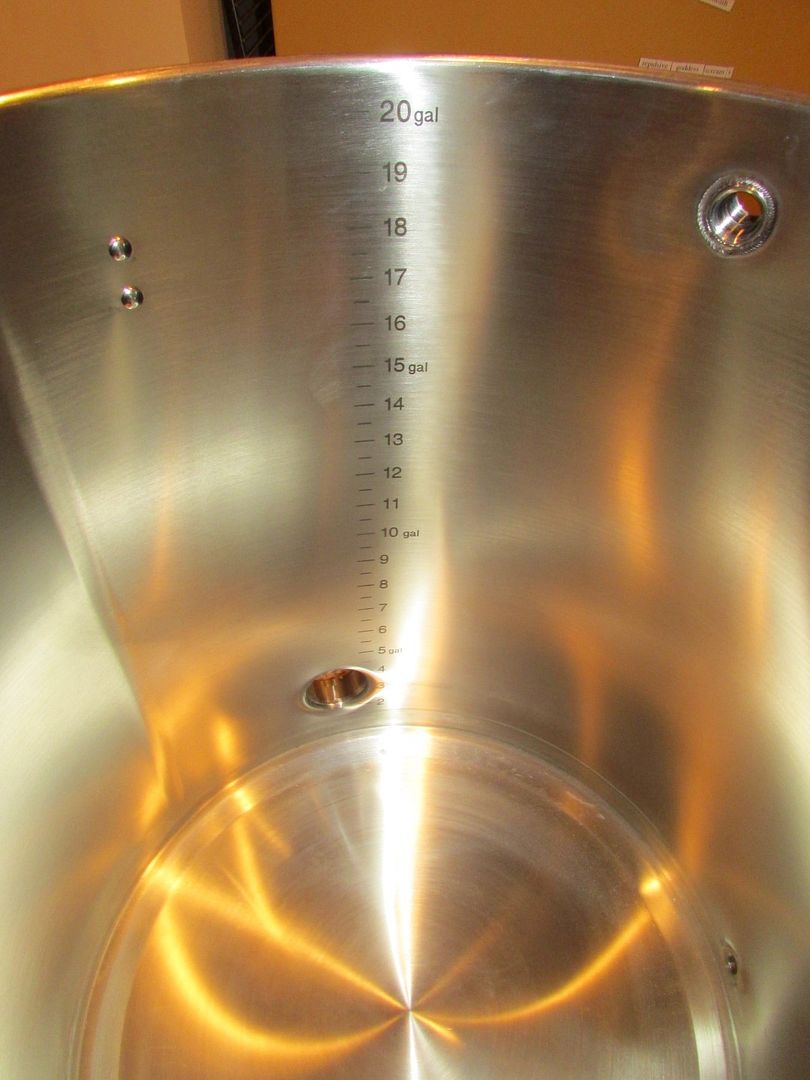

gallon markings on the interior, with the tri-clamp connection at the bottom and recirc water inlet on the top:

internal weld detail. amazing:

bottom of the kettle. tri-clad bottom, very heavy. good for direct fire or induction:

internal shot of the tri-clamp fitting:

lid hanging on the side handle:

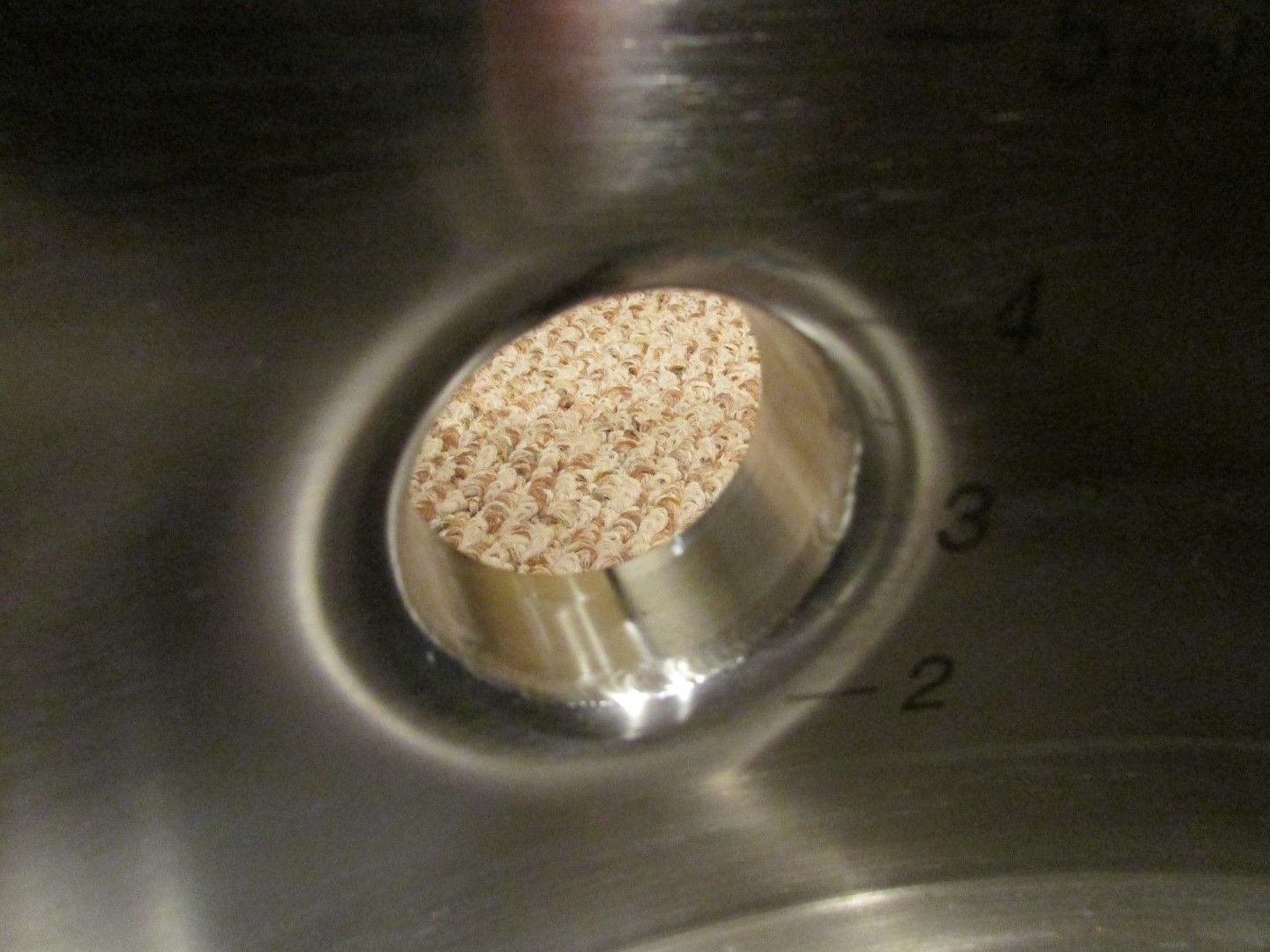

dip tube connection. only about 1/8" off the bottom, maybe less:

sight glass attached to the kettle:

and a test spot on the brew stand. kettle is a monster, those are 750 ml bottles next to it:

the weight of this thing is insane. very solid. hard to balance on the scale but it reads 21 pounds:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)