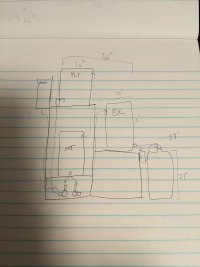

I finished an electric control panel and now it's time to build a frame. I have a previously build two tier frame made of ankle iron I could use I guess, but I wanted to make it more compact now. (its like 5-6 feet long)

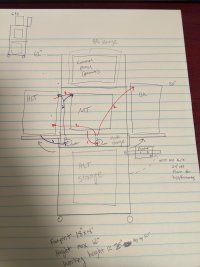

I'm not set on 2, 2.5, 3 tier designs just yet but I know i want the boil kettle high to allow for plate chilling into my fermonsters. I have two pumps so I don't really care if HLT is above or below MT. I liked the tree design bc it's more compact but maybe harder to weld sturdy. I even thought of a single riser with the three tuns rotating around it like the old Blichman TopTier but again structural integrity matters. Can't be dropping my 15 gallon keggle because of poor welding or design.

I will like to mount the E-panel to the side somewhere, probably the left based on where I'm envisioning this being. Anyone have clear input on why one design, height, order, might be better than another? One reason to have MT above the BK in a 2.5 tier is if a pump dies then I can still do my HERMs mash and gravity drain into the keggle. I'm 5'10" ad I'd like this keggle to be no higher than 5' off the ground for comfortable use.

I'm not set on 2, 2.5, 3 tier designs just yet but I know i want the boil kettle high to allow for plate chilling into my fermonsters. I have two pumps so I don't really care if HLT is above or below MT. I liked the tree design bc it's more compact but maybe harder to weld sturdy. I even thought of a single riser with the three tuns rotating around it like the old Blichman TopTier but again structural integrity matters. Can't be dropping my 15 gallon keggle because of poor welding or design.

I will like to mount the E-panel to the side somewhere, probably the left based on where I'm envisioning this being. Anyone have clear input on why one design, height, order, might be better than another? One reason to have MT above the BK in a 2.5 tier is if a pump dies then I can still do my HERMs mash and gravity drain into the keggle. I'm 5'10" ad I'd like this keggle to be no higher than 5' off the ground for comfortable use.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)