Lmiller1708

Member

Hey Guys Looking for some advice...

As you can see from my setup I have two Avantco IC1800's and a large 15 gallon pot. I plan on doing 5 Gallon BIAB batches and was advised to go big or go home (just incase I wanted to do a 10 gallon batch)!

With this setup I was able to boil 7 gallons with the lid ON after ~80 minutes starting from 55 deg F. The power was set to 13 on each burner or ~1400 watts ~2800 total (measured ~12 amps @ 118 vac). I figured out I was at about 56% efficiency. I guess reading through this thread that seems to be OK?. However with the lid OFF I can't hold a boil... I can with the lid just cracked but not sure I want to do that in fear of bad beer. I have also tried using Reflectix insulation with no luck.

I know my setup has a few issues which are better explained with pictures.

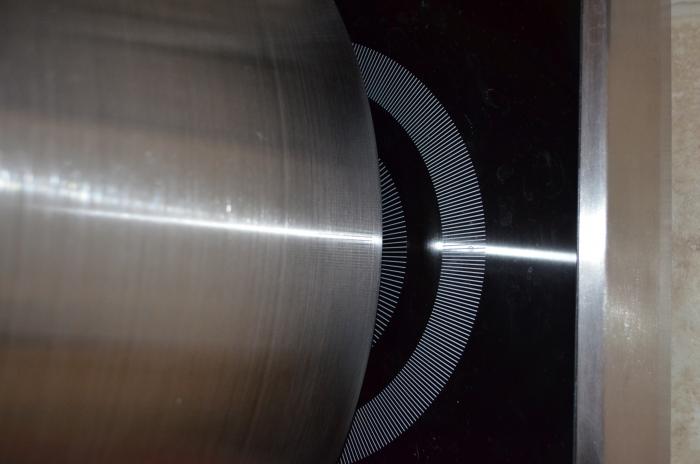

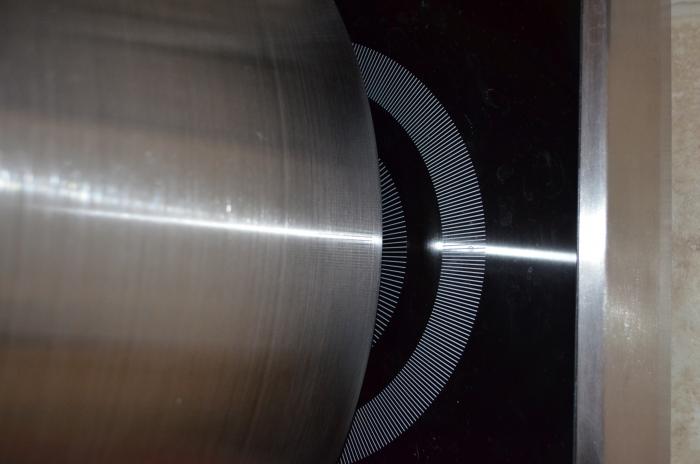

1. The pot is just on the edge of the inner burner. This was my fault when buying it as I didn't take in account the gap between the two burners.

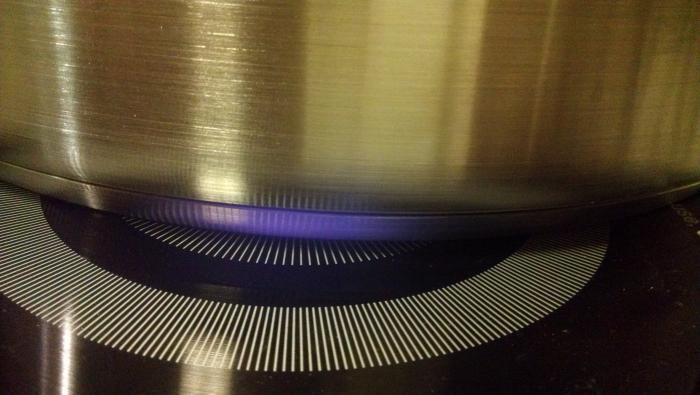

2. The pot in not fully touching the plate because the aluminum is too high in some places. Kinda hard to see the gap, but you can get the point. I think I could help this by shaving down the aluminum around the burners.

Because of these issues I can't get above the 13 setting without the bottom edge of the pot glowing red. Over all I like the setup, but if it wasn't for the darn 30% restocking fee from thewebresturant store I would have sent them back and got an IC3500.

Now you know where I'm at... I'm looking for some advice.

Should I just let good enough alone and brew with the lid slightly cracked (~1 inch)?

Should I shave down the aluminum and possibly void any warranty I had in hopes to get better conductivity between the pot and burners.

Bite the bullet and return the burners for an IC3500 model? Would take about a 80 dollar hit plus S&H. I'm assuming this model has the same problems with the aluminum being too high...

Thanks for any help!

As you can see from my setup I have two Avantco IC1800's and a large 15 gallon pot. I plan on doing 5 Gallon BIAB batches and was advised to go big or go home (just incase I wanted to do a 10 gallon batch)!

With this setup I was able to boil 7 gallons with the lid ON after ~80 minutes starting from 55 deg F. The power was set to 13 on each burner or ~1400 watts ~2800 total (measured ~12 amps @ 118 vac). I figured out I was at about 56% efficiency. I guess reading through this thread that seems to be OK?. However with the lid OFF I can't hold a boil... I can with the lid just cracked but not sure I want to do that in fear of bad beer. I have also tried using Reflectix insulation with no luck.

I know my setup has a few issues which are better explained with pictures.

1. The pot is just on the edge of the inner burner. This was my fault when buying it as I didn't take in account the gap between the two burners.

2. The pot in not fully touching the plate because the aluminum is too high in some places. Kinda hard to see the gap, but you can get the point. I think I could help this by shaving down the aluminum around the burners.

Because of these issues I can't get above the 13 setting without the bottom edge of the pot glowing red. Over all I like the setup, but if it wasn't for the darn 30% restocking fee from thewebresturant store I would have sent them back and got an IC3500.

Now you know where I'm at... I'm looking for some advice.

Should I just let good enough alone and brew with the lid slightly cracked (~1 inch)?

Should I shave down the aluminum and possibly void any warranty I had in hopes to get better conductivity between the pot and burners.

Bite the bullet and return the burners for an IC3500 model? Would take about a 80 dollar hit plus S&H. I'm assuming this model has the same problems with the aluminum being too high...

Thanks for any help!