You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you LOVE your job...

- Thread starter T_Baggins

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

n240sxguy

Well-Known Member

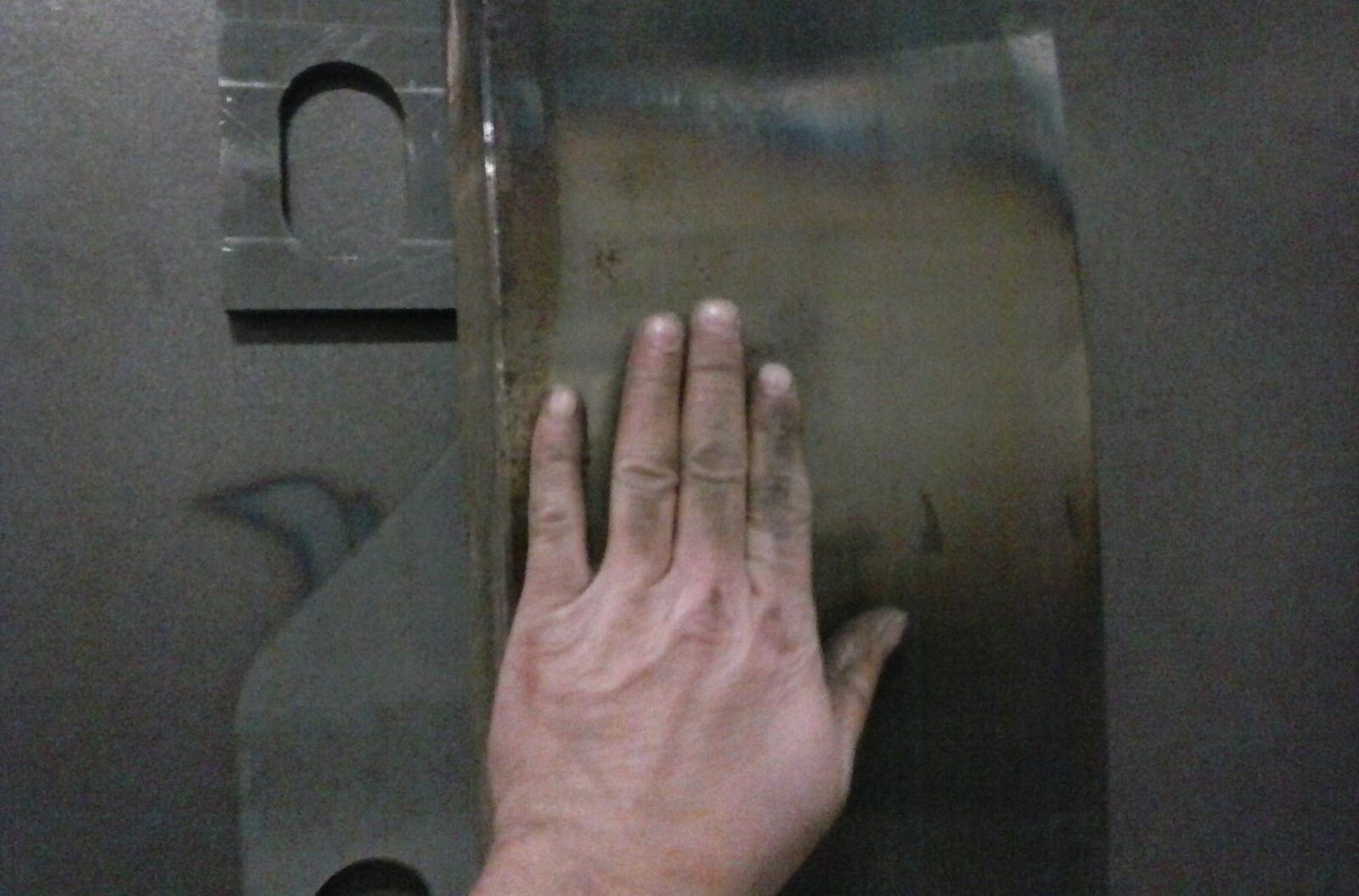

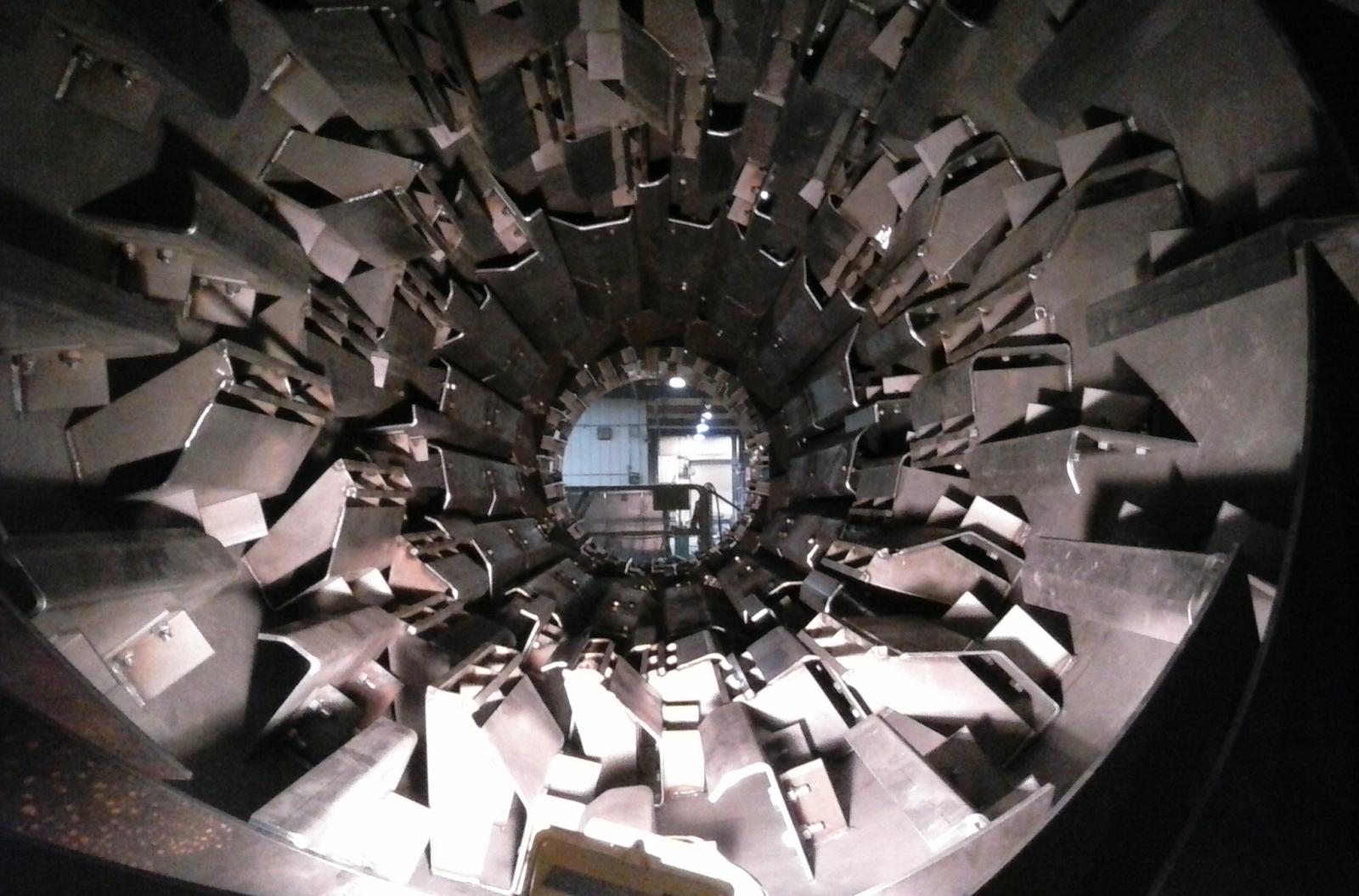

Another LARGE (46,000lbs+) chunk of steel! This guy makes asphalt...

That's crazy inside! I'll have to see if I can sneak a couple pics when our new reactor shows up in February. You'd appreciate it. The entire thing has to be heat treated and brick lined.

bottlebomber

Well-Known Member

That's gnarly, basically on the direct other end of the manufacturing spectrum from where I am at

bottlebomber

Well-Known Member

edited just because

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

T_Baggins

Well-Known Member

- Joined

- Apr 2, 2013

- Messages

- 822

- Reaction score

- 87

This is something I worked on recently, it's a dielectric half-spoke that goes into a hermetic seal. The drill it's sitting on in the magnified picture is just over the size of a human hair. Sorry the image quality is poor, I was holding my iPhone up to a 50x scope. View attachment 246041View attachment 246042

pretty good image for what you had...that's bad ass... now can you THREAD those holes?

bottlebomber

Well-Known Member

pretty good image for what you had...that's bad ass... now can you THREAD those holes?

I can indeed sir, and, I can make the mating screw threads as well

liquiditynerd

Well-Known Member

- Joined

- Sep 6, 2008

- Messages

- 681

- Reaction score

- 104

I can indeed sir, and, I can make the mating screw threads as wellI haven't found anything too small for these machines to make, there's just a point where you are absolutely not going to find it after the part-off

Damn, BB, I thought you were messing for a moment. I was trying to figure our how a red pencil was dielectric? That's freaking bad ass!

bottlebomber

Well-Known Member

Damn, BB, I thought you were messing for a moment. I was trying to figure our how a red pencil was dielectric? That's freaking bad ass!

Lots of cool stuff going on here. Wafer fab, growing yttrium iron garnets for our signal generators, chemical milling, laser micro-machining, everything that isn't some kind of plastic is typically gold plated. It's like a fairyland for anyone in manufacturing.

littletommy

Well-Known Member

- Joined

- Jan 4, 2013

- Messages

- 304

- Reaction score

- 88

I work in a hot dog stand factory. Yes, we build hot dog stands, well, trailers that you would see at the state fair, not just hot dog trailers. We also build mobile stages, and big specialty semi type trailers. I run a press brake, so I mainly just stand in front of a huge puke green machine all day. I don't love it, but I could do worse. I'm not freezing my ass off in the winter, or melting in the blazing sun in the summer, the money is good, and we shut down at Christmas time every year for two weeks. I'm not allowed to take photos in the shop.

I'm hoping to be able to quit in a 3 or 4 years and start making custom holsters and sheaths full time, just no time to do things I want to do now.

I'm hoping to be able to quit in a 3 or 4 years and start making custom holsters and sheaths full time, just no time to do things I want to do now.

twisted_metal

Active Member

I'm a Railway Carman, (Freight Car Mechanic). The guy that fixes all the things behind the Locomotives and some of the things on the Locomotive. I Re-Rail things that have been de-railed. Cut, Weld, Fix, Make, Maintain and Service All things Railcar.

1. Talking on the phone. (Yep its F'd)(2008), 2. First Day on the Road Truck (2007), 3. Same as above, 4. SELFIES!!! (on the right)2014

1. Talking on the phone. (Yep its F'd)(2008), 2. First Day on the Road Truck (2007), 3. Same as above, 4. SELFIES!!! (on the right)2014

Natdavis777

Well-Known Member

I dont love my job, used to hate it, but has since gotten better due to decreased management. Im a CT Technologist now, but used to be a union laborer. It was really my first real job(started at 17 still in high school) and hated it for the first few years. One of my best friends, whom I met because he worked with me, and myself miss it to this day. He is now a freight broker @ a fortune 500 Co here in the city.

We make good money today, but its the actual work we miss. We talk about it time to time. The absence of political bull****. I miss pouring 100 yds of mud or doing some grade work or busting rod. It was hard work but honestly that was the job I loved. The only reason I dont go back is bc Im greedy with the paycheck I make now, and I only work 3 days a week.

We make good money today, but its the actual work we miss. We talk about it time to time. The absence of political bull****. I miss pouring 100 yds of mud or doing some grade work or busting rod. It was hard work but honestly that was the job I loved. The only reason I dont go back is bc Im greedy with the paycheck I make now, and I only work 3 days a week.

I'm a Control room operator at a power plant. Started off as a mechanic then became an electrician then I moved into operations. I couldn't imagine any other job I'd enjoy more, we'll besides owning my own brewery..

View attachment 1421480421991.jpg

View attachment 1421480421991.jpg

I'm a Control room operator at a power plant. Started off as a mechanic then became an electrician then I moved into operations. I couldn't imagine any other job I'd enjoy more, we'll besides owning my own brewery..

And apparently I can spin the world upside down.

Almost there. One more beer and you'll be right side up again.

Silly phone won't let me post pics correctly. Now that I'm home from work I'll take you up on those beers!

Komocabo

Well-Known Member

- Joined

- Oct 16, 2012

- Messages

- 1,083

- Reaction score

- 159

how long should I see bubbles in my airlock?

Now THAT is a blow off!

n240sxguy

Well-Known Member

I'm a Control room operator at a power plant. Started off as a mechanic then became an electrician then I moved into operations. I couldn't imagine any other job I'd enjoy more, we'll besides owning my own brewery..

I'm an operator at a chemical plant. We work 12 hour swing, and I love it. Some people say they couldn't handle it, but I like it.

Just like Homer Simpson. Mmmmm. Donuts

About the only difference is we eat chips and salsa instead of donuts. And I sleep more than him

I'm an operator at a chemical plant. We work 12 hour swing, and I love it. Some people say they couldn't handle it, but I like it.

We work a 4 on 5 off 5 on 4 off 12 hour schedule. I love it! A couple months ago I stepped in as the temporary head trainer, so I went to mon-friday 7a-3p. I hated it! I have become acclimated to the long stretches of days off. It affords me time for my hobbies!

I'm an operator at a chemical plant. We work 12 hour swing, and I love it. Some people say they couldn't handle it, but I like it.

I also work at a chemical plant and do swing shifts. I didn't think I would like it at first but I do. The way ours works out is its the same schedule every 4 weeks. We work 14 days and get 14 days off. 7 of those are in a row. Thats the week I get in a couple brew sessions and bottle my previous batches. I think its a sweet schedule.

n240sxguy

Well-Known Member

I also work at a chemical plant and do swing shifts. I didn't think I would like it at first but I do. The way ours works out is its the same schedule every 4 weeks. We work 14 days and get 14 days off. 7 of those are in a row. Thats the week I get in a couple brew sessions and bottle my previous batches. I think its a sweet schedule.

Mine is a rolling 4 week schedule too. I work 6-6. 4 days, 6 off, 4 nights, 4 off, 3 days, 3 nights, 4 off.

pointcity-homebrew

Crafting openers 1 at a time

I love my job. I work for a University in their High Voltage Lab, the largest owned my a University in the USA.

We do testing and verification for industry. Occasionally we have some research projects. I work with 1 million VAC and 3 Million VDC impulse.

We do testing and verification for industry. Occasionally we have some research projects. I work with 1 million VAC and 3 Million VDC impulse.

Mine is a rolling 4 week schedule too. I work 6-6. 4 days, 6 off, 4 nights, 4 off, 3 days, 3 nights, 4 off.

6:30-6:30 for us. Coming back from the 7 day break we work 4 nights, 3 off, 3 days, 1 off, 3 nights, 3 off, 4 days, 7 off. Monday I'll start my 4 days then I get the 7 off. I'm looking forward to it. I didnt brew last time as I didnt have time during the holidays. I have an empty fermentation chamber and thats unacceptable!

n240sxguy

Well-Known Member

I love my job. I work for a University in their High Voltage Lab, the largest owned my a University in the USA.

We do testing and verification for industry. Occasionally we have some research projects. I work with 1 million VAC and 3 Million VDC impulse.

That's cool. When I sold electrical supplies I went on a tour/training trip to Allen-Bradley in Milwaukee. They have the only privately owned UL listed lab, or at least they did at the time. They would test high amperage fuses to make sure the trip curve was correct. I didn't get to see it in action, but I saw the scars on the bullet proof glass in front of the control room. Crazy stuff.

The school I work for recently added a broadcasting curriculum. We have also secured partnerships with the Arizona Diamondbacks, The Phoenix Suns and NASCAR. On top of that, our entire broadcast curriculum was written by a guy who mixes the Super Bowl. Super awesome guy by the name of Fred Aldous.

We go out to these events and show our students how to set up the audio side of the broadcast world. Then they get a real world scenario (where they can't mess anything up) and they get to mix the event.

We go out to these events and show our students how to set up the audio side of the broadcast world. Then they get a real world scenario (where they can't mess anything up) and they get to mix the event.

Similar threads

- Replies

- 17

- Views

- 793

Latest posts

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: BongoYodeler

-

-

-

-

-