JoshuaW

Well-Known Member

Im hoping you might have a better idea of what is going on before I spend the money to freight this back to the manufacturer.

I purchased some Chinese made equipment, and it is not within electrical spec. I had spec'd US 220V, 60hz. What I received is 220V 60hz, but the space for the incoming power is only two wires, labeled for hot and neutral. As we all know, 220/240v in the US is three wires, two hot, one neutral (and sometimes one ground). The manufacturer wants me to send back the equipment to be corrected, but before I do that, I want to know if there is any way to correct this. It will probably cost me a very substantial amount in freight to send everything back, so I dont really want to do that unless absolutely necissary. On the other hand, I will completely lose all warranty and support if I do anything to it, but that is a minimal worry to me, since it will cost me an asinine amount of freight to have anything corrected.

Im also worried that if I have any work on it done here, will that impact the existing components? Heating elements, probably not. What about pumps and the glycol chiller though?

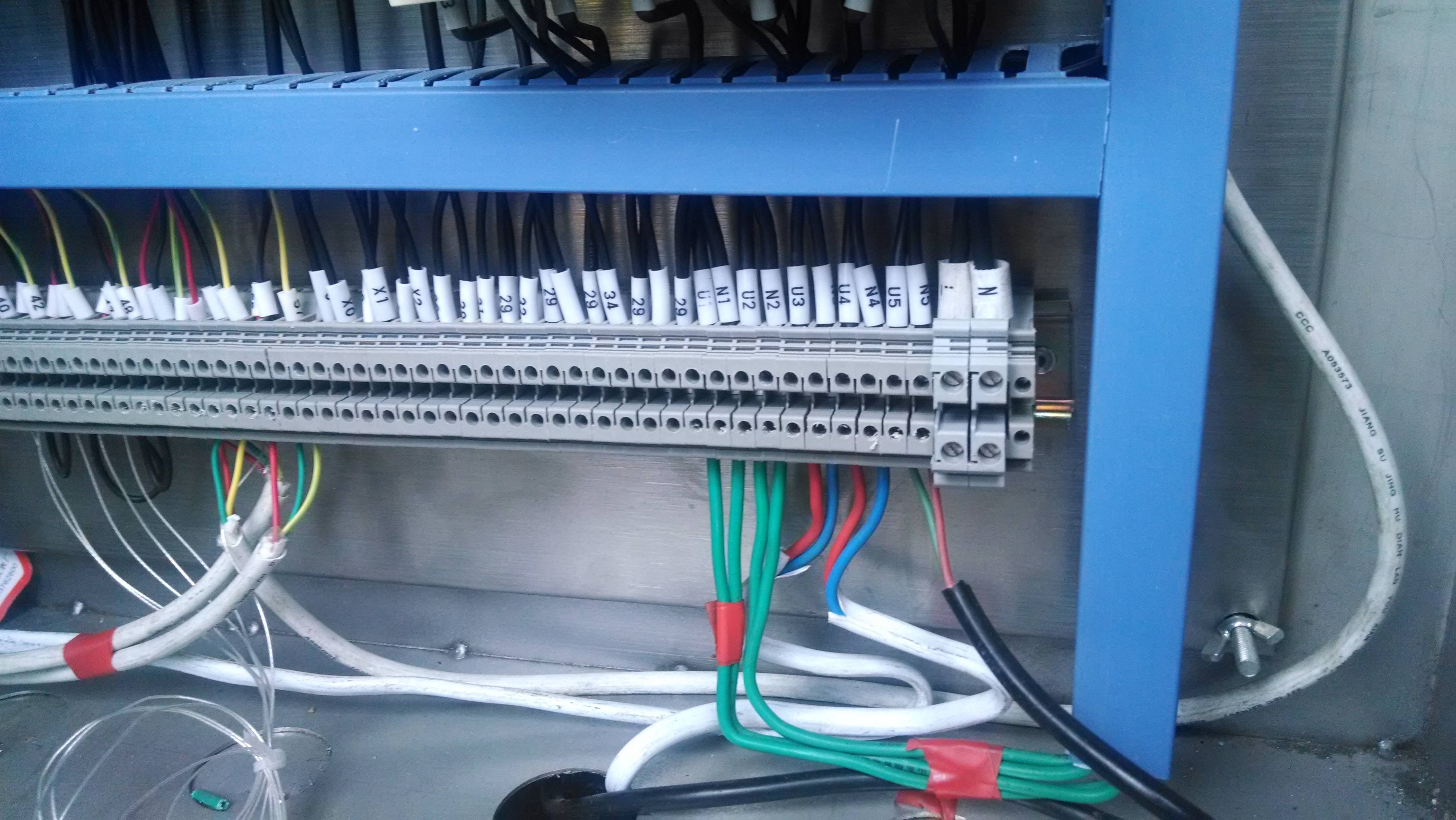

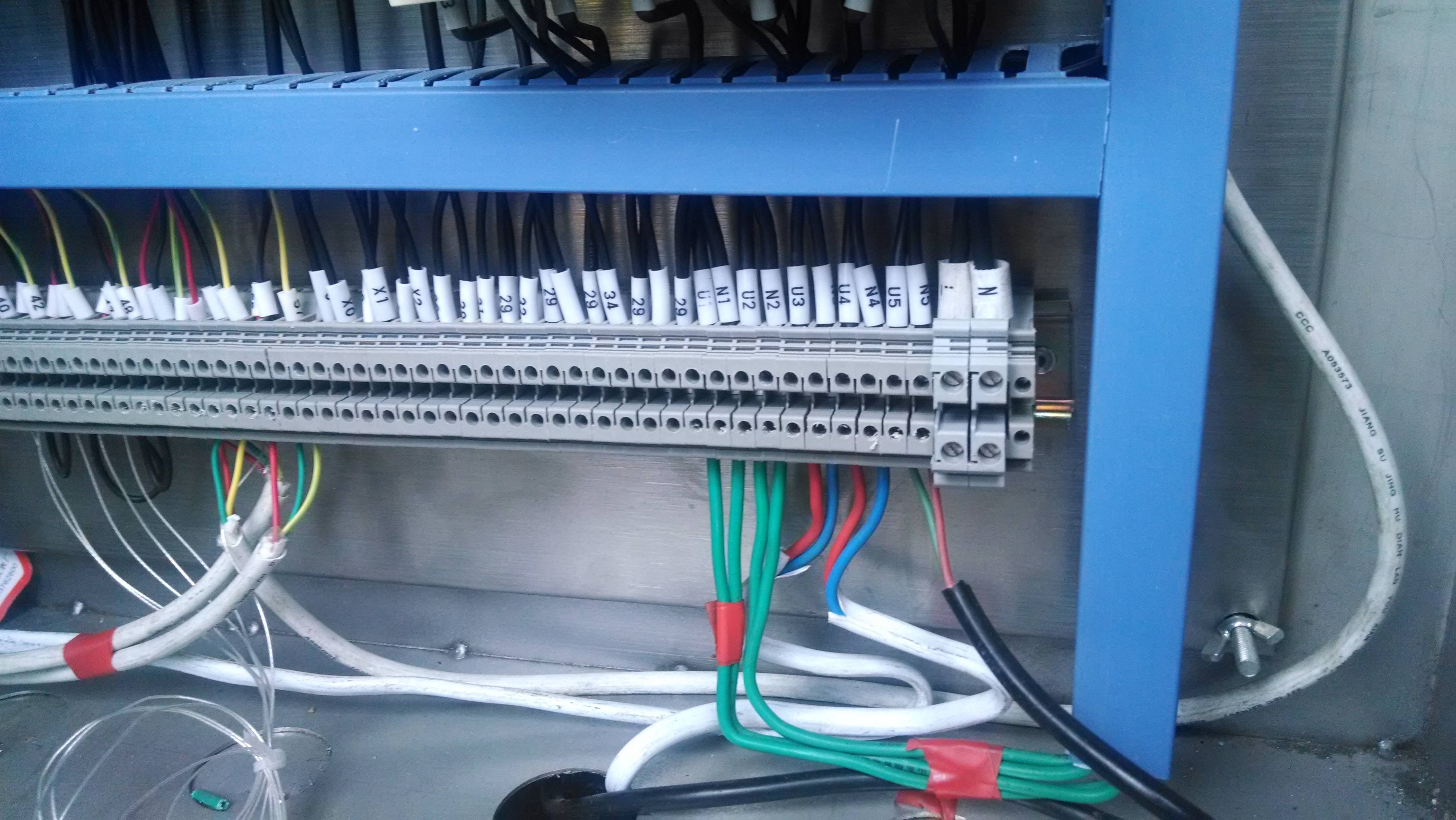

Here are the handful of pictures I have. I will take more pictures of the interior of the panel this afternoon, as well as any pictures of specific closeups any of you might need to get a better idea of what is going on.

This is where the power was supposed to be hooked up:

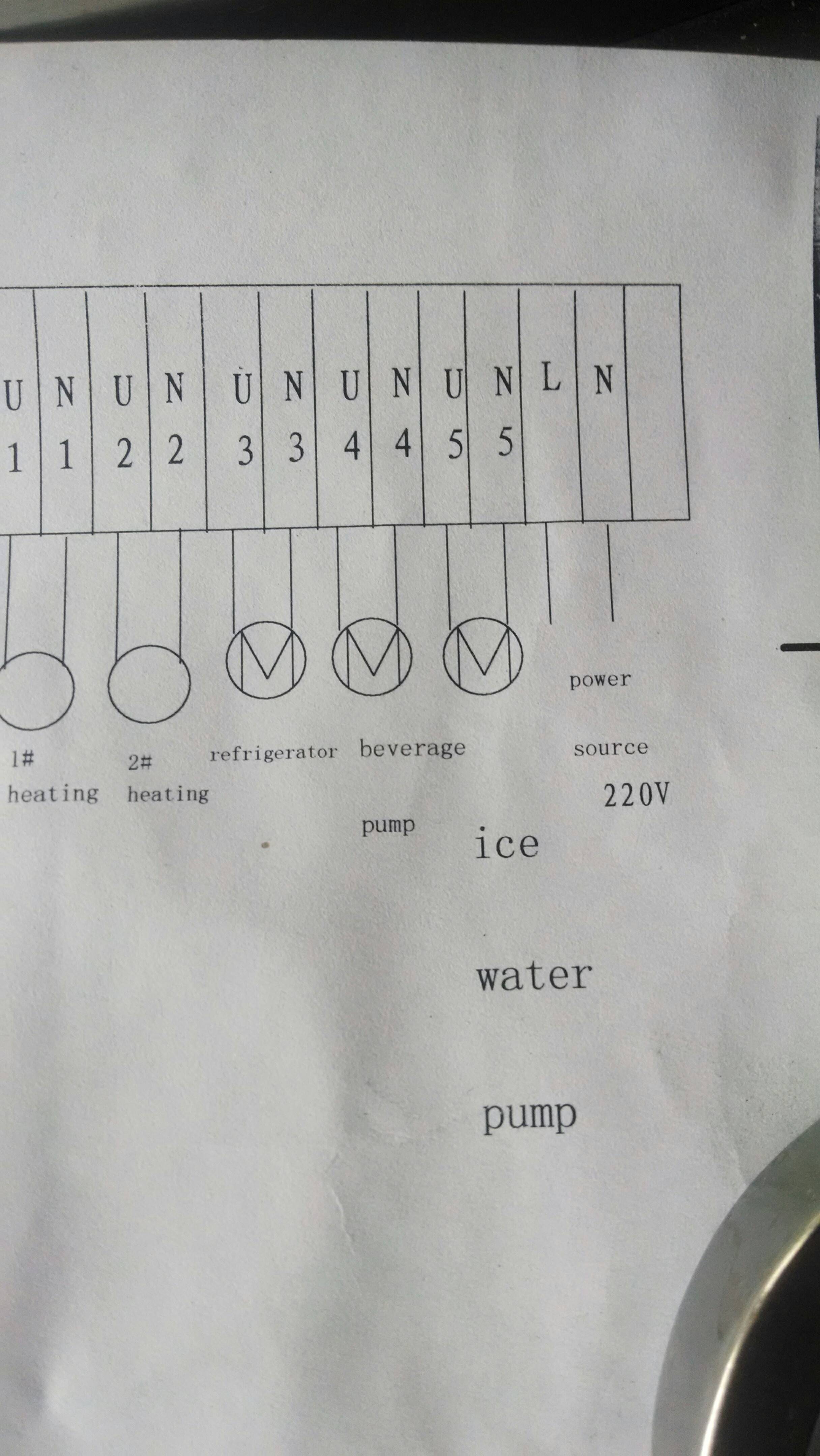

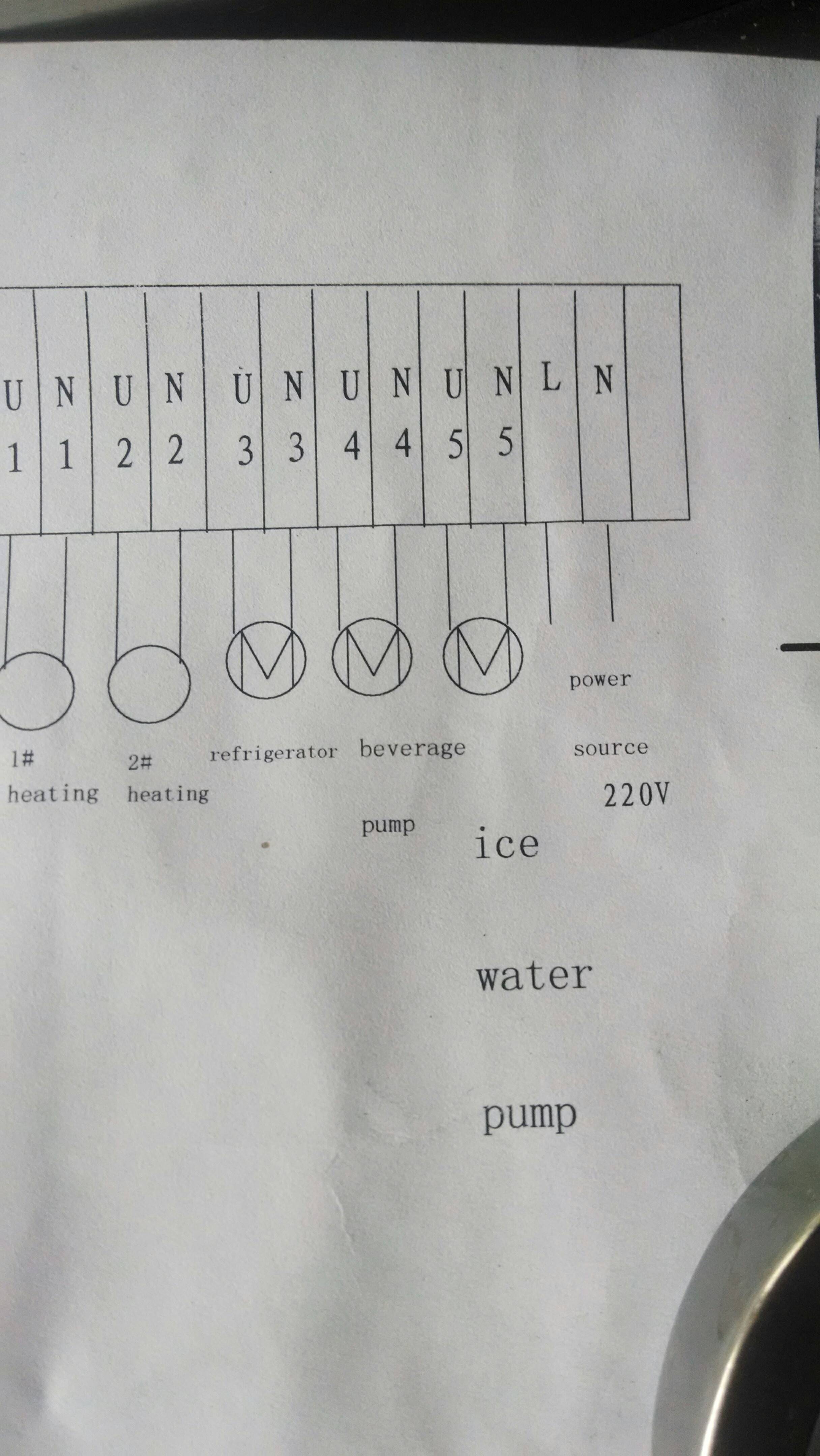

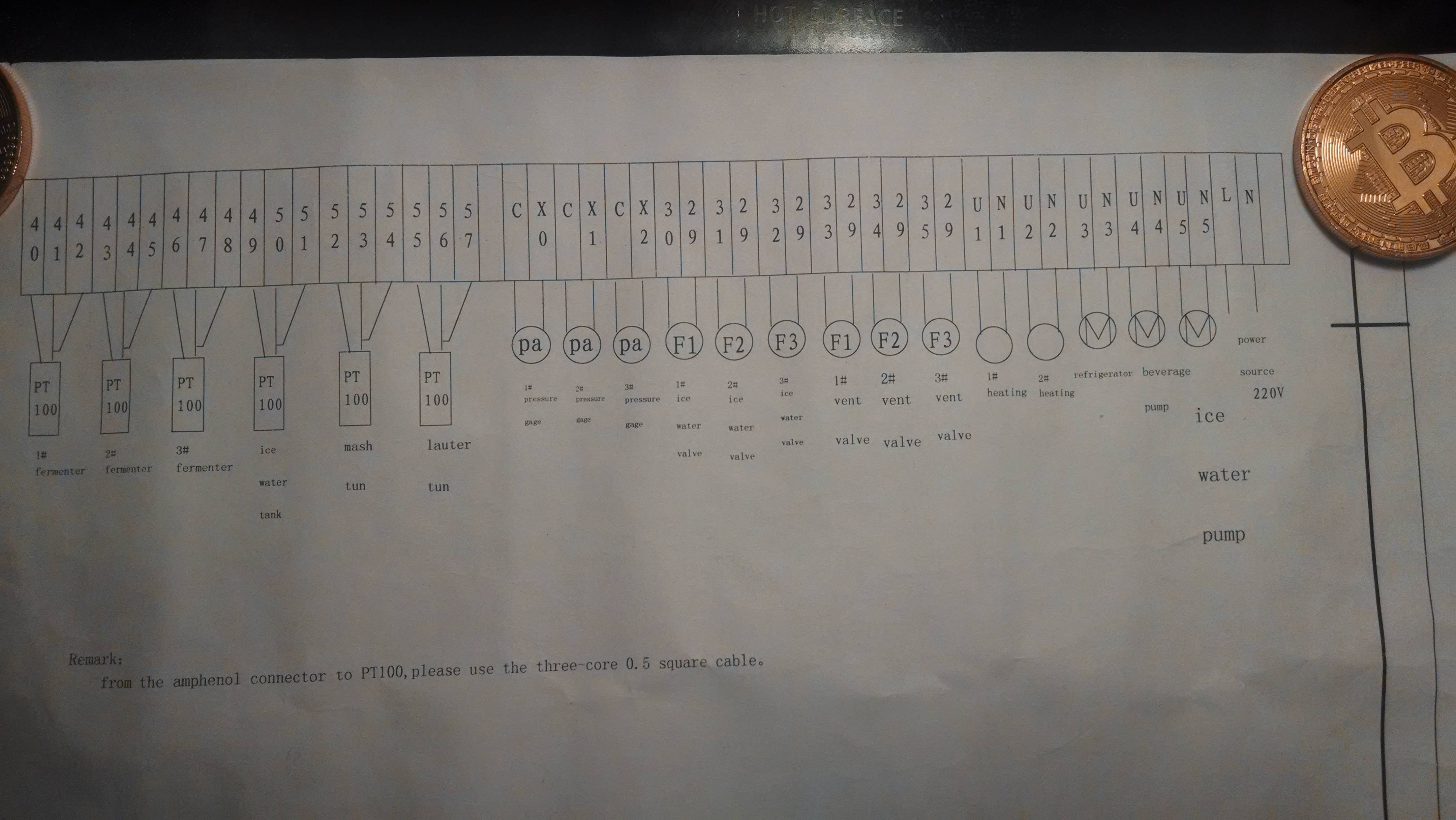

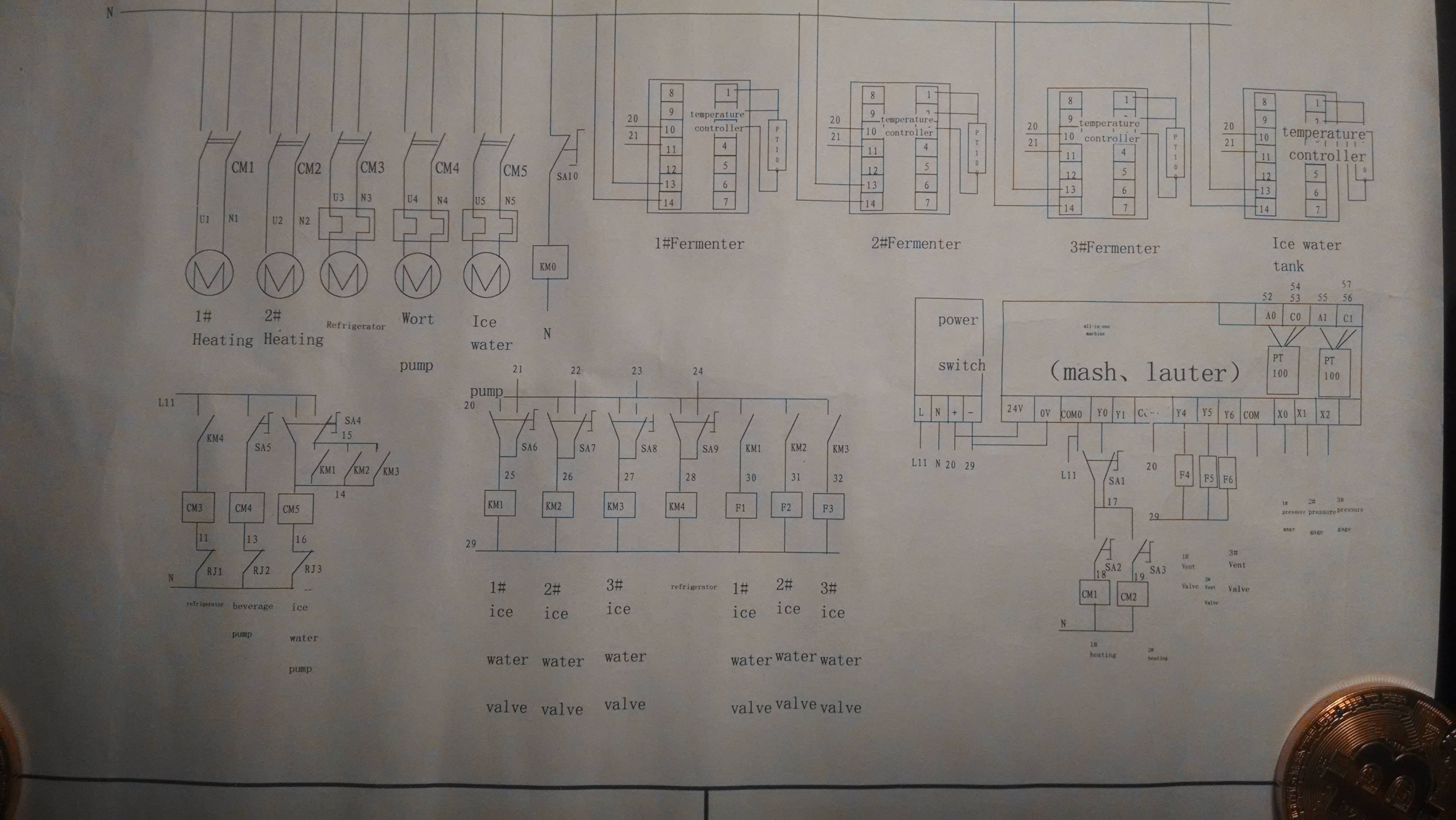

This is the wiring "diagram" included

This is the front of the panel. Nothing overtly more complex than a Kal Clone, other than the PLC. The PLC has a power supply on the inside of the panel, so I dont think that is a concern.

I purchased some Chinese made equipment, and it is not within electrical spec. I had spec'd US 220V, 60hz. What I received is 220V 60hz, but the space for the incoming power is only two wires, labeled for hot and neutral. As we all know, 220/240v in the US is three wires, two hot, one neutral (and sometimes one ground). The manufacturer wants me to send back the equipment to be corrected, but before I do that, I want to know if there is any way to correct this. It will probably cost me a very substantial amount in freight to send everything back, so I dont really want to do that unless absolutely necissary. On the other hand, I will completely lose all warranty and support if I do anything to it, but that is a minimal worry to me, since it will cost me an asinine amount of freight to have anything corrected.

Im also worried that if I have any work on it done here, will that impact the existing components? Heating elements, probably not. What about pumps and the glycol chiller though?

Here are the handful of pictures I have. I will take more pictures of the interior of the panel this afternoon, as well as any pictures of specific closeups any of you might need to get a better idea of what is going on.

This is where the power was supposed to be hooked up:

This is the wiring "diagram" included

This is the front of the panel. Nothing overtly more complex than a Kal Clone, other than the PLC. The PLC has a power supply on the inside of the panel, so I dont think that is a concern.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

)

)