gigapunk said:Thank you for the help guys, I've spent some time reading about AC current trying to learn as much as I can.

So in the above schematic with a neutral and one hot 220v lead going to the PID, is the PID then powered by 110V (even though it does not have a second hot lead)? Could the PID alternatively be powered by two hot leads to 9 and 10?

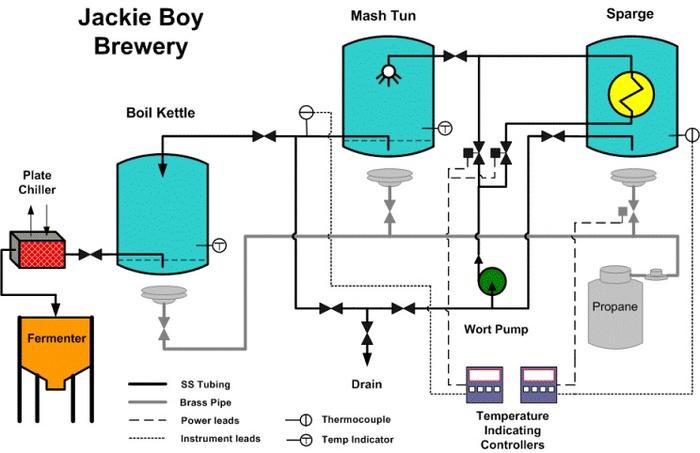

If the PID is designed for 110v it could hurt it to power it with 220v. The diagram that was provided above is great for what you are trying to do. It provides 220v to the heating element and 110v to the controller. If you follow the line diagram you should be ok.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)