Damonic

Well-Known Member

I plan on following this project faithfully... best of luck with the rest of the build!

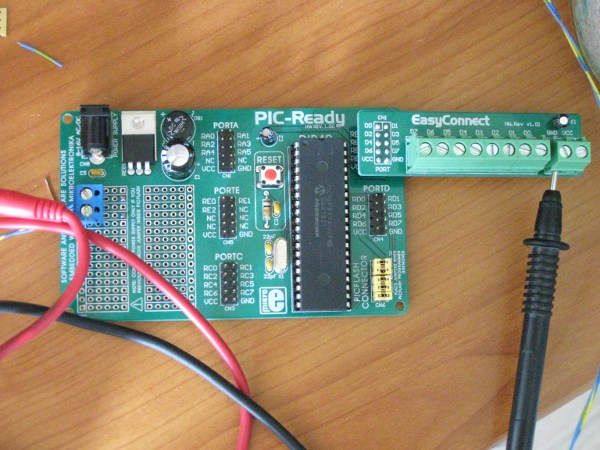

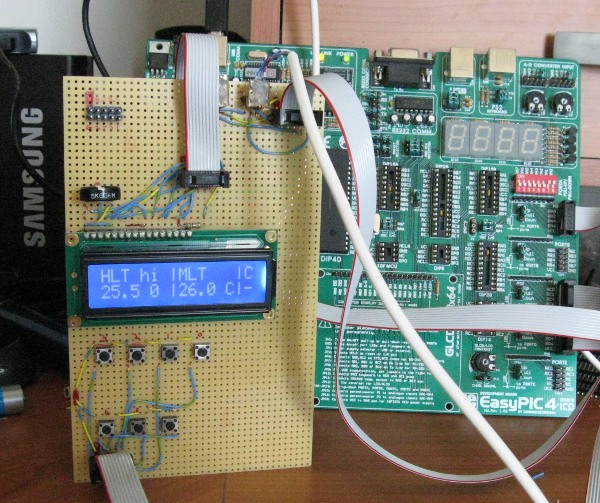

I made a demo video where I show the temperature controller (that I now call KarmaControl)

Video quality is quite bad - and somehow my accent became Swedish in the upload...strange

[SNIP

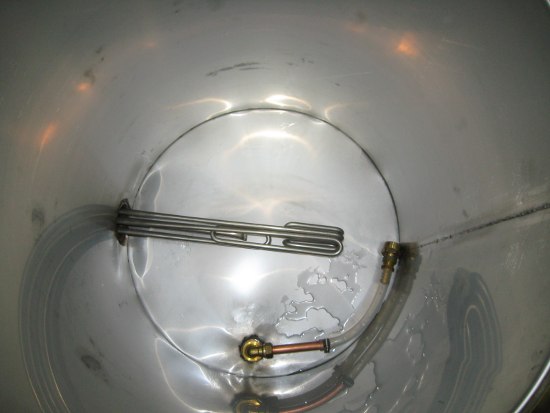

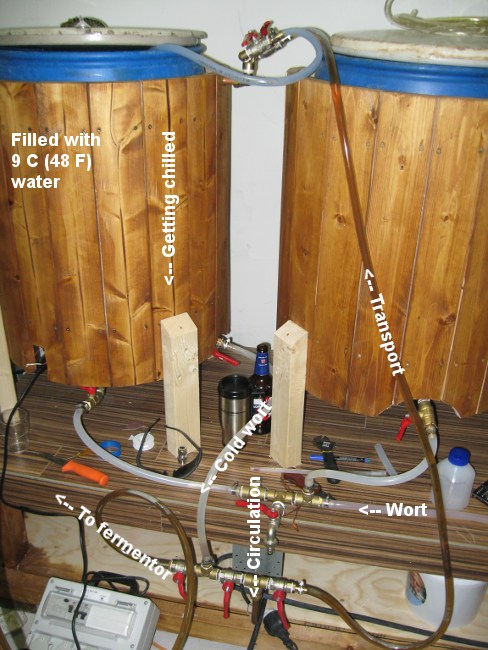

Aiming to do the first brew on the system today.

looks good! Any plans to stain the "rocket feet"?

Just one question, how tall is it to the rim on top of the brewcart and the 'rocket feet'? Are you a giant? or will you need a step/milk crate?

Congrats on the brew day!

How do you remove the spent grains from your mash tun?

Went to bed around 7.30 AM so it was more a brew night than a brew day

is this one of those crazy times of year in sweden where it stays light or dark all the time??

seriously, this is one of the coolest builds i've seen. what a way to make your dagligen brod!

can't wait to see it all done.

I do have a one of those HUGE plastic barrels (100 gallons?) that bulk LME comes in though.. I'm pretty sure I could score 2 more from local ubrews, but I think that is for another day.

100 gallons....wow that would be an awesome project. Would probably need a barn to house a 100 gallon E-HERMS sysem....and a powerplant to run it