Just wanted to share a bit about the think process regarding the programming and creation of the controller.

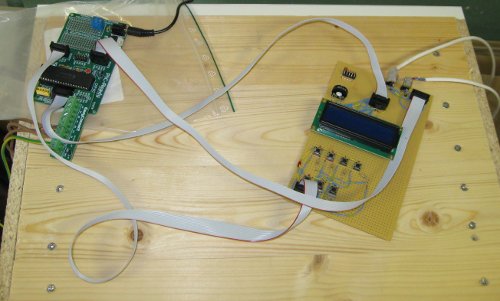

The idea that I am working with now is to have a very simple interface and interaction with the user (which at the moment would be me and SWMBO).

So...4 buttons is all that is required....did however add 3 more buttons, just in case I will do some future improvements later on.

When the controller is powered on, it will automatically go into a setup stage, with default settings that doesn't need to be changed unless you would like to brew special types of beer.

First setting is HLT delta temperature setting (i.e. how much hotter should the HLT be than the MLT).

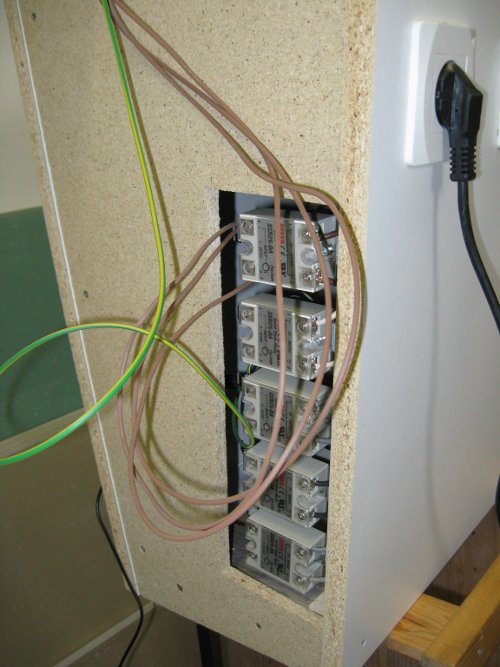

Second setting allows the user to configure how the HLT effect steps should be used in the modes HI, MED, REG(ulation). E.g. user can have 3 separate heating elements in "HI" mode and only use 1 for "REG" mode.

Third setting is to set/confirm the different MLT rest temperatures.

Currently have 4 steps defined with the default values:

Rest 1: 50 C (122 F)

Rest 2: 60 C (140 F)

Rest 3: 68 C (155 F)

Rest 4: 78 C (172 F)

That's it....when this third setting is done, the user is taken into pre-runtime mode where a "Water in HLT?" confirmation is needed.

When in runtime (i.e. when brewing) it's easy to switch between the different rests.

The idea that I am working with now is to have a very simple interface and interaction with the user (which at the moment would be me and SWMBO).

So...4 buttons is all that is required....did however add 3 more buttons, just in case I will do some future improvements later on.

When the controller is powered on, it will automatically go into a setup stage, with default settings that doesn't need to be changed unless you would like to brew special types of beer.

First setting is HLT delta temperature setting (i.e. how much hotter should the HLT be than the MLT).

Second setting allows the user to configure how the HLT effect steps should be used in the modes HI, MED, REG(ulation). E.g. user can have 3 separate heating elements in "HI" mode and only use 1 for "REG" mode.

Third setting is to set/confirm the different MLT rest temperatures.

Currently have 4 steps defined with the default values:

Rest 1: 50 C (122 F)

Rest 2: 60 C (140 F)

Rest 3: 68 C (155 F)

Rest 4: 78 C (172 F)

That's it....when this third setting is done, the user is taken into pre-runtime mode where a "Water in HLT?" confirmation is needed.

When in runtime (i.e. when brewing) it's easy to switch between the different rests.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)