Not exhausted...More relieved. I just brewed yesterday after not brewing for 6 months, due to being too damn busy to brew. Went well, but I do brew differently than most. I do a partial boil(4 gallons), then top off in fermenter. I still put in about 11lbs of grain(dependent on recipe), with the appropriate amount of heated water into a mash tun. But only get 4 gallons of wort(after sparging). Boil 60 minutes, then top off in the fermenter. Up and down a set of steps a few times. But never exhausted. My brewday is about 4 hrs this way.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I brewed today... man am I bushed!

- Thread starter MrBJones

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I make a brew day way more work than it needs to be. I should get better at having sparge water ready and get a wort chiller.

I am also over the top with my sanitation process. All that adds time. I'm usually pitching yeast well after midnight.

I am also over the top with my sanitation process. All that adds time. I'm usually pitching yeast well after midnight.

Yeah, @Kent88, but you’re talking about efficiency, not effort. Many of us could be more efficient with our time. We use long, controlled mashes, long, slow spares, and a 90 minutes boil. You would think with all this white space, we would be ready for the next step, but often it catches us by surprise. Maybe I should brew solo to keep my focus...

MaryB

Well-Known Member

I do prep the day before, everything weighed, grains crushed, water in mash tun and HLT with any mineral additives needed. Brew day I turn on the MT burner and get it up to temp, mash in, at 30 minutes I heat the sparge water, fly sparge at 60 minutes, when the HLT is empty I fire up the BK burner, when the MT is drained I take it off the burner, scoop grain to a bucket(s) while sitting on a chair, cold water rinse/green scrubby the MT and dry it off and put it back on the burner, dump the grains in the garden to compost or in the compost bin depending on time of year, by this time the BK is almost at a boil so I watch and stir(11 gallon batches in a 15 gallon kettle. Boil overs are very very close!), once things are at a boil and first hops are in I kick back and rest during the 60 minute boil, at 30 minutes put IC in the BK to sterilize and swirl sanitizer in the fermenters and dump it. Add hops etc as needed of course. After boil cool, drain to the fermenters. Put them in the wagon and pull it from the garage to my front door where I carry it 10 feet to planter rollers on wheels to roll it to my pantry. Pull wagon back, scrub BK and rinse(or soak every 10 batches with PBW) then done for the day

Sure I am tired when done but I have everything down to where I am not wasting any time. I am doing something during every stage of the brew day to minimize the time spent brewing.

Sure I am tired when done but I have everything down to where I am not wasting any time. I am doing something during every stage of the brew day to minimize the time spent brewing.

I have my set up as easy as possible- but it's still a long and tiring day for me. When I was younger, I didn't mind it as much but these days I sort of dread brew day as much as I look forward to it.

I'm still doing 11 gallon batches, since it's just as much work for 11 gallons as it is for 5, but I'm thinking that as time passes I might do something else, like a picobrew or something.

When I added pumps and things about 10 years ago, it did make things easier for me and about 8 years ago I added a tippy dump but it's still hauling grain outside and things. I have a few ages and pains anyway so it's not as fun as it used to be.

Funny you mention that, as I have kind of the same mind-set. I really enjoy brew day, and I look forward to it. But when I get up that morning I'm a little apprehensive. It's like "oh, crap, I have a lot of work to do." Setup and cleanup are the most tedious.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

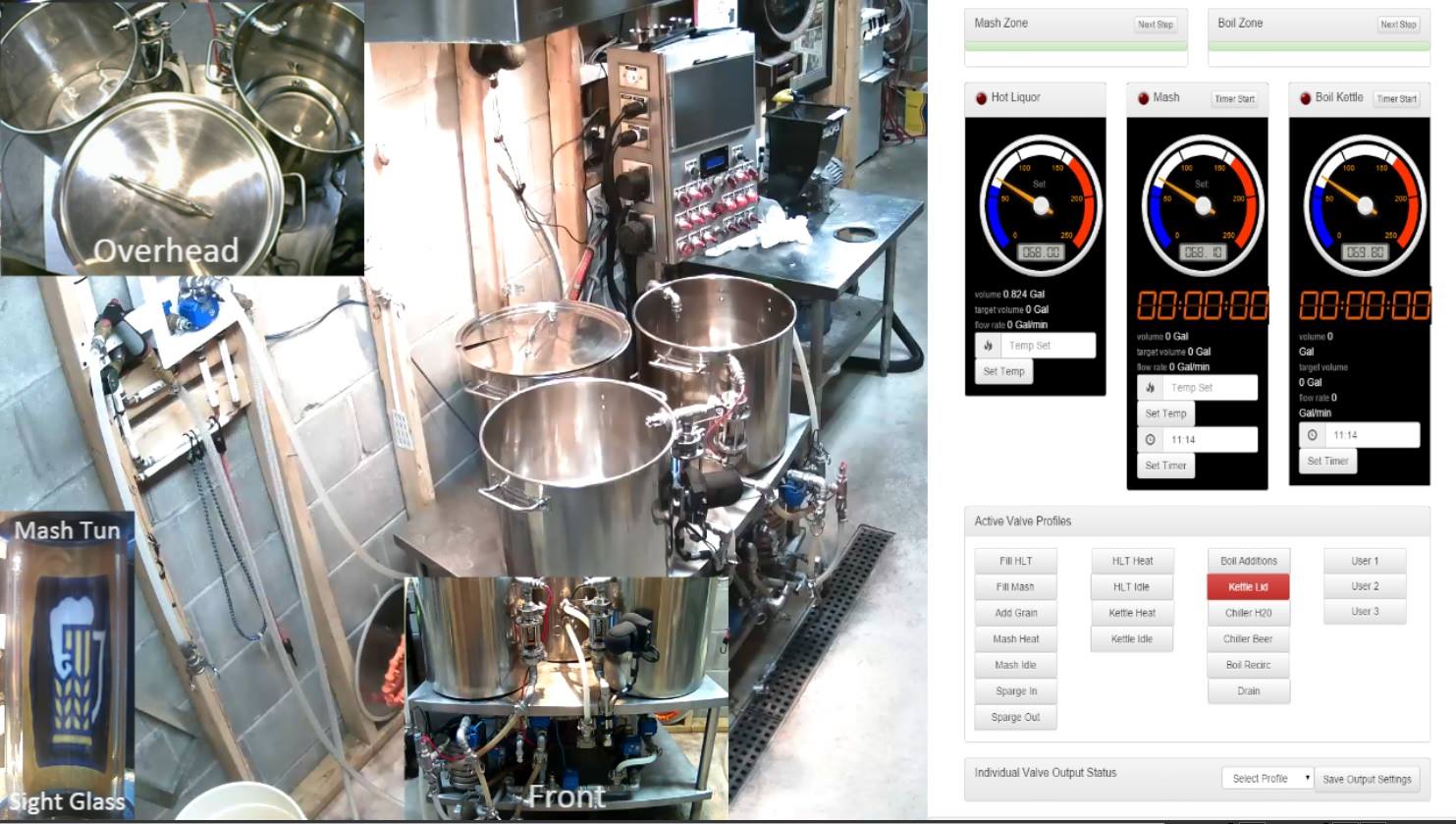

Nope I brew remotely!

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

applescrap

Be the ball!

Its physical and while I am so blessed to be able to easily lift 11 g of wort and dump in 2 fermenters without spilling a drop, I am not gettng any younger. I have the utmost respect for brewers who figure out how to use pumps, etc..to make brewing happen for them. They have a lot they can teach a Homer simpson like me. No matter what its physical, either grains move or the water does (later grains get removed). Even stirring the mash. Since I brew so quickly its even more physical, a grind. Ill be on a zymatic as well before to long.

I have my set up as easy as possible- but it's still a long and tiring day for me. When I was younger, I didn't mind it as much but these days I sort of dread brew day as much as I look forward to it.

I'm still doing 11 gallon batches, since it's just as much work for 11 gallons as it is for 5, but I'm thinking that as time passes I might do something else, like a picobrew or something.

When I added pumps and things about 10 years ago, it did make things easier for me and about 8 years ago I added a tippy dump but it's still hauling grain outside and things. I have a few ages and pains anyway so it's not as fun as it used to be.

I agree, hauling the grain basket out is heavy as heck.... I wish i could come up with an easier way to take apart and clean the kettle hoses pump etc...

I'm always beat after a brew day. It's a one-man show for me. I do my BIAB mash in my kitchen and then carry the kettle outside for the boil. Probably not the best idea but it helps hold the temp better. I usually start heating water around 9am and get the fermenter put into the chamber around 3pm. Then cleaning for at least 1 hour. I find that drinking several glasses of water and some ibuprofen really helps. And no drinking beer until the fermenter is in the chamber.

I need to find a brew buddy.

I need to find a brew buddy.

I make a brew day way more work than it needs to be. I should get better at having sparge water ready and get a wort chiller.

I am also over the top with my sanitation process. All that adds time. I'm usually pitching yeast well after midnight.

A chiller will knock a lot of time off brew day. The ice bath method is very time-consuming. If you like DIY projects, you can make an IC for around $30 in parts. Or buy a basic one for a little more. Well worth the $$.

SlitheryDee

General Manager

It wasn't that bad for me until I moved up to 10 gallon batches. Then it went from manageable to impossible. I tried mashing overnight inside my shed like usual, and when it came time to move the kettle to the burner outside I found that I just barely could manage it. My new kettle has a spigot, which is the only thing that saved me really. I was able to let out enough of the hot wort into a bucket to be able to lift the kettle to a table. Had to go no-chill because I couldn't get the kettle to the sink where I usually hook up the immersion chiller.

I still made beer, but next brew day is going to involve some pre-planning. Need a water hose to run to my kettle for chilling, a short table to raise everything up enough that I can let the wort out directly into the fermenters, and a better means of insulation since I'm probably going to be mashing overnight outdoors during winter because I flat out can't move the kettle when it's full.

I still made beer, but next brew day is going to involve some pre-planning. Need a water hose to run to my kettle for chilling, a short table to raise everything up enough that I can let the wort out directly into the fermenters, and a better means of insulation since I'm probably going to be mashing overnight outdoors during winter because I flat out can't move the kettle when it's full.

The ice bath method is very time-consuming. If you like DIY projects, you can make an IC for around $30 in parts. Or buy a basic one for a little more.

I think that the ice bath method works quicker than I thought, but still a long time. The part of the kettle that isn't in contact with icewater takes forever to cool even if the submerged part of the kettle and the wort within is practically lager temp.

So, being partly submerged in cold water while I run to the gas station for a couple bags of ice, and then when I get back I change the water and start adding ice, that all does the trick. And this is just for a 3-gallon batch.

And that is the other issue. Most ICs that I have seen aren't for smaller kettles (though I doubt that would be a big issue), and I don't have an indoor faucet that I can hook up an IC to even if I made one custom.

Barley_Bob

Well-Known Member

This is a really interesting thread.

My first response would be, "Get in better shape." I think that's still a good answer, but after reading this, I can see why that isn't a great answer for many. I'm still going to plug it for a moment though - I'm managing two herniated disks and some impaired nerve function from a third. Staying in shape is extremely important to me. I'm trying to make it to 50 before I have surgery. At the end of the day, pushing myself to exercise is way cheaper and way less damaging that corrective surgery will be. Even a light exercise regimen should help.

Ibuprofen before brewing is also a good call. Taking an anti-inflammatory before exercise is proven to reduce inflammation better than taking it after inflammation begins.

Beyond that, I do things in stages. It's more for time savings on brew days, but I crush my grain at least a day before the brew and I move my fermenter to the basement the day after the brew. It helps.

The two hardest items I have to tackle are moving the 5 gallon containers of water up the stairs on brew day and then taking the fermenter downstairs when chilling is complete. The latter is the absolute worst. Carrying an uneven, bulky load down a narrow flight of stairs is really hard, and it puts a lot of strain on my disks. If anyone has a good suggestion for that, I am all ears.

Edit: To chill, I just pour the hot wort into the fermenter and then leave the fermenter outside overnight in even reasonably cool weather. It works fine. I haven't had any change in beer quality or in rate of infection. I literally just have to walk the bucket to the front porch. It's quick, easy, and then I toss in yeast and move the fermenter to the basement the next morning. In the summer I have to work a little harder, but for 9 months out of the year, chilling is very low effort.

My first response would be, "Get in better shape." I think that's still a good answer, but after reading this, I can see why that isn't a great answer for many. I'm still going to plug it for a moment though - I'm managing two herniated disks and some impaired nerve function from a third. Staying in shape is extremely important to me. I'm trying to make it to 50 before I have surgery. At the end of the day, pushing myself to exercise is way cheaper and way less damaging that corrective surgery will be. Even a light exercise regimen should help.

Ibuprofen before brewing is also a good call. Taking an anti-inflammatory before exercise is proven to reduce inflammation better than taking it after inflammation begins.

Beyond that, I do things in stages. It's more for time savings on brew days, but I crush my grain at least a day before the brew and I move my fermenter to the basement the day after the brew. It helps.

The two hardest items I have to tackle are moving the 5 gallon containers of water up the stairs on brew day and then taking the fermenter downstairs when chilling is complete. The latter is the absolute worst. Carrying an uneven, bulky load down a narrow flight of stairs is really hard, and it puts a lot of strain on my disks. If anyone has a good suggestion for that, I am all ears.

Edit: To chill, I just pour the hot wort into the fermenter and then leave the fermenter outside overnight in even reasonably cool weather. It works fine. I haven't had any change in beer quality or in rate of infection. I literally just have to walk the bucket to the front porch. It's quick, easy, and then I toss in yeast and move the fermenter to the basement the next morning. In the summer I have to work a little harder, but for 9 months out of the year, chilling is very low effort.

I think the key, as with anything in life, is knowing your limits and finding ways to work smarter as others have said.

I'm 46 and keep in good shape, but I still am tired at the end of the day. I had microdiscectomy 10 years ago and find staying in shape is the only way I can avoid pain. When I designed my current setup I had efficiency and ease of use in mind and it's night and day compared to my old system. Having pumps, tippy dump, CIP, and all my brewing gear in one location has made a world of difference, but all this convenience did not come cheap.

My last system had to be moved from on top of garage cabinets to my outdoor BBQ area at the back of the house: 1 hour set up and tear down each. I would usually set up the day before just to split the workload.

As for tips to reduce fatigue:

1) Rubber Mats: most of the brew day is spent standing. It's remarkable how much good mats relieve leg and back pain

2) Consolidate: try to carve out a dedicated space with everything near by.

3) Split the work: as others have said, break up the tasks

4) NSAIDs before

5) Find People who have chickens or other livestock: Let them haul your spent grains away

6) Reduce volume of liquids being lifted: Sure you're still lifting 80+ lbs of water, but far easier to lift 20lbs 4 times than all 80 at once. I used to fill my carboys all the way with StarSAN while boiling. Then I realized, I just need to add 1 gal, swoosh around and drain upside down. Less wasted water, too

7) Pumps and Automation: makes a world of difference. If you can't afford March or Chuggers they sell cheap pumps at your local home improvement stores that can be connect to cordless drills (obviously not for hot liquids, just moving pre-strike water)

8) Proper nutrition: I'm also a cyclist. As with any sport, proper nutrition the day before an activity, and during goes a long way to reducing fatigue. I used to be so busy with brew days that I'ld often barely eat breakfast and then skip lunch. Now I eat a good meal the night before and make sure I eat during a brew day. This alone makes a big difference. Hydrate! I'm my not talking about the malty sudsy stuff we all love so much. I save my well earned beer for after.

I'm 46 and keep in good shape, but I still am tired at the end of the day. I had microdiscectomy 10 years ago and find staying in shape is the only way I can avoid pain. When I designed my current setup I had efficiency and ease of use in mind and it's night and day compared to my old system. Having pumps, tippy dump, CIP, and all my brewing gear in one location has made a world of difference, but all this convenience did not come cheap.

My last system had to be moved from on top of garage cabinets to my outdoor BBQ area at the back of the house: 1 hour set up and tear down each. I would usually set up the day before just to split the workload.

As for tips to reduce fatigue:

1) Rubber Mats: most of the brew day is spent standing. It's remarkable how much good mats relieve leg and back pain

2) Consolidate: try to carve out a dedicated space with everything near by.

3) Split the work: as others have said, break up the tasks

4) NSAIDs before

5) Find People who have chickens or other livestock: Let them haul your spent grains away

6) Reduce volume of liquids being lifted: Sure you're still lifting 80+ lbs of water, but far easier to lift 20lbs 4 times than all 80 at once. I used to fill my carboys all the way with StarSAN while boiling. Then I realized, I just need to add 1 gal, swoosh around and drain upside down. Less wasted water, too

7) Pumps and Automation: makes a world of difference. If you can't afford March or Chuggers they sell cheap pumps at your local home improvement stores that can be connect to cordless drills (obviously not for hot liquids, just moving pre-strike water)

8) Proper nutrition: I'm also a cyclist. As with any sport, proper nutrition the day before an activity, and during goes a long way to reducing fatigue. I used to be so busy with brew days that I'ld often barely eat breakfast and then skip lunch. Now I eat a good meal the night before and make sure I eat during a brew day. This alone makes a big difference. Hydrate! I'm my not talking about the malty sudsy stuff we all love so much. I save my well earned beer for after.

Mine take exactly 6.5 hours from start to finish (everything cleaned up and put away) I have been brewing 1 to 2 times a month for a long time and I am used to it. I did move to doing 3 gallon batches most of the time as the grain bills are around 7-8 pounds and it keeps me brewing often which I like.

applescrap

Be the ball!

My first response would be, "Get in better shape."

Carrying an uneven, bulky load down a narrow flight of stairs is really hard, and it puts a lot of strain on my disks. If anyone has a good suggestion for that, I am all ears.

Get in better shape!

This is a really interesting thread.

My first response would be, "Get in better shape." I think that's still a good answer, but after reading this, I can see why that isn't a great answer for many. I'm still going to plug it for a moment though - I'm managing two herniated disks and some impaired nerve function from a third. Staying in shape is extremely important to me. I'm trying to make it to 50 before I have surgery. At the end of the day, pushing myself to exercise is way cheaper and way less damaging that corrective surgery will be. Even a light exercise regimen should help.

Ibuprofen before brewing is also a good call. Taking an anti-inflammatory before exercise is proven to reduce inflammation better than taking it after inflammation begins.

Beyond that, I do things in stages. It's more for time savings on brew days, but I crush my grain at least a day before the brew and I move my fermenter to the basement the day after the brew. It helps.

The two hardest items I have to tackle are moving the 5 gallon containers of water up the stairs on brew day and then taking the fermenter downstairs when chilling is complete. The latter is the absolute worst. Carrying an uneven, bulky load down a narrow flight of stairs is really hard, and it puts a lot of strain on my disks. If anyone has a good suggestion for that, I am all ears.

Edit: To chill, I just pour the hot wort into the fermenter and then leave the fermenter outside overnight in even reasonably cool weather. It works fine. I haven't had any change in beer quality or in rate of infection. I literally just have to walk the bucket to the front porch. It's quick, easy, and then I toss in yeast and move the fermenter to the basement the next morning. In the summer I have to work a little harder, but for 9 months out of the year, chilling is very low effort.

Stairs and older bodies are never a good idea and herniated disks make it much worse. Is there any way you can make modifications to the downstairs area so you do it all down there? Changing plumbing, electrical, lighting, etc are still going to be cheaper than back surgery and cheaper than the hospital visit when you fall on the stair with a 5 gallon container.

GHBWNY

Well-Known Member

Stairs and older bodies are never a good idea and herniated disks make it much worse. Is there any way you can make modifications to the downstairs area so you do it all down there?

Last year I took a couple months off my regular work (custom carpentry/remodeling) and remodeled our small c.1958 kitchen. Removed a supporting wall and opened the new kitchen up into the garage along with a new entry way, new subpanel to tie everything in (by code, new kitchens need a lot more dedicated circuits than they did in 1958), new windows, doors, drywall, plumbing, lights, outlets, floor, etc., etc.. AND... a new laundry room off the kitchen which my wife insisted she didn't want/need because it was her "exercise" to trudge up and down the basement stairs with loads of laundry. After my insistence, she gave in and has mentioned no less than 100 times how glad she is that I insisted on it, esp. now that everything is on the first floor (ranch house). In the process, she suggested that I turn the old laundry room downstairs into a brew room! WHAT??!! Why didn't I think of that?!

The new arrangement is a blessing for both of us, and definitely a luxury neither of us ever imagined. We're both getting to "that age" where her lugging baskets of laundry up and down stairs and me negotiating a trip (npi) down the stairs with my bifocals while carrying a 5-gal kettle of boiling wort were becoming a liability. And likely, the precursor to a herniated disc, if not a good scalding.

Comments about "getting in shape" aside, the answer is adapting equipment and processes to one's ability. There are ways to improve accessibility of gear, shortening workflow movement, using pumps, hoists, rolling stands, etc. to move materials; rearranging plumbing, wiring, etc. Or having a friend or family member to help. As RM-MN stated, it's better to change things around than to endure back surgery.

I am fortunate that I am physically able to do typical brewing tasks, though I'm getting to the point where I need to think about simplifying the process down the road. I'm not too far from 60. While not exhausted, the brew day does take a lot out of me. I don't know yet what changes I will incorporate, though I'm looking at all the possibilities. Maybe eBIAB, with the right array of pumps to move liquids from vessel to vessel.

I also do some woodworking--building furniture and doing woodturning. And the usual home-repairs. There are online groups devoted to helping woodworkers with disabilities enjoy the hobby. I've met several wheelchair-bound people who are able to enjoy the pastime to the fullest. You can do it, you just have to adapt.

There is no one-size-fits-all way to do things. But the technology is there to enable just about anyone to brew successfully. You just have to be creative.

This is a good thread, and a worthwhile topic. It's made me think about my brewing adventures in the future. I enjoy this hobby too much to give it up.

I am fortunate that I am physically able to do typical brewing tasks, though I'm getting to the point where I need to think about simplifying the process down the road. I'm not too far from 60. While not exhausted, the brew day does take a lot out of me. I don't know yet what changes I will incorporate, though I'm looking at all the possibilities. Maybe eBIAB, with the right array of pumps to move liquids from vessel to vessel.

I also do some woodworking--building furniture and doing woodturning. And the usual home-repairs. There are online groups devoted to helping woodworkers with disabilities enjoy the hobby. I've met several wheelchair-bound people who are able to enjoy the pastime to the fullest. You can do it, you just have to adapt.

There is no one-size-fits-all way to do things. But the technology is there to enable just about anyone to brew successfully. You just have to be creative.

This is a good thread, and a worthwhile topic. It's made me think about my brewing adventures in the future. I enjoy this hobby too much to give it up.

Glad to see this posted, (not sure why). It's nice to know I'm not the only one who feels utterly spent after a brew day. On top of being fat old and out of shape, I also have severe back issues. At the end of a brew day I'm physically and mentally exhausted, but the real fun comes the two days afterwards - where I can barely walk.

I've always been in good shape and up until my 40's most of my jobs were the "strong back - weak mind" type. So to be so physically whipped after 6 to 8 hours of brewing was discouraging. I'm seriously debating dropping back to 2.5 to 3 gallon batches. It's taken me 2 years to get my 3 keggle system (kind of) where I want it, but as others have noted - keggles are heavy even when they're empty. I keep all my equipment in the garage and I was brewing on the back patio, but for the past 4 or 5 brews I just open the garage door and set everything up there with a fan blowing out.

And even so, it's still a pretty brutal day.

I've always been in good shape and up until my 40's most of my jobs were the "strong back - weak mind" type. So to be so physically whipped after 6 to 8 hours of brewing was discouraging. I'm seriously debating dropping back to 2.5 to 3 gallon batches. It's taken me 2 years to get my 3 keggle system (kind of) where I want it, but as others have noted - keggles are heavy even when they're empty. I keep all my equipment in the garage and I was brewing on the back patio, but for the past 4 or 5 brews I just open the garage door and set everything up there with a fan blowing out.

And even so, it's still a pretty brutal day.

A friend and I did a 10 gallon triple decoction on a Czech Pils Friday and I was sore the next day. I'll probably never do another triple decoction but I had to try it.

When I started brewing again 7-8 years ago, I went to five gallon batches (I used to do 10). I'm 60 now and I don't think I could do 10 gallons on my own with my setup.

The tiring part of brewing a normal 5 gallon batch is schlepping everything except the burner up the stairs to the garage and then back down. I need to put in an electric brewery in the basement so I can end the trips up and down the stairs.

When I started brewing again 7-8 years ago, I went to five gallon batches (I used to do 10). I'm 60 now and I don't think I could do 10 gallons on my own with my setup.

The tiring part of brewing a normal 5 gallon batch is schlepping everything except the burner up the stairs to the garage and then back down. I need to put in an electric brewery in the basement so I can end the trips up and down the stairs.

For those of you with bad backs who have to haul around 5-6 gallon carboys full of wort down stairs, I definitely found the carboy straps to be a huge help. Makes schlepping around the weight a bit easier and definitely safer IMO.

For those of you with bad backs who have to haul around 5-6 gallon carboys full of wort down stairs, I definitely found the carboy straps to be a huge help. Makes schlepping around the weight a bit easier and definitely safer IMO.

This. Carboys are slippery. Best $12 investment for safety. Plastic milk crates are great for that, too. The real ones, not the flimsy excuses for crates you find in the home storage section of Target.

triethylborane

Well-Known Member

Comments about "getting in shape" aside

This is the ideal male body; you may not like it, but this is what peak performance looks like:

Last edited by a moderator:

Barley_Bob

Well-Known Member

Stairs and older bodies are never a good idea and herniated disks make it much worse. Is there any way you can make modifications to the downstairs area so you do it all down there? Changing plumbing, electrical, lighting, etc are still going to be cheaper than back surgery and cheaper than the hospital visit when you fall on the stair with a 5 gallon container.

I've been thinking about getting some kind of electric induction plate for my mash and boil. If I did that, I just about could do everything in my basement. If I eventually installed a mop sink with a threaded faucet for a wort chiller and for cleanup, I really would never have to split the process between floors.

Coincidentally, my wife hates sharing the kitchen with me when I brew. She would totally support this idea.

With these modifications, I would still have to carry 5 gallon jugs of water up and down the stairs, but I find that carrying a balanced load (so not just one heavy bucket) is a lot easier.

Cheesy_Goodness

Well-Known Member

I'm usually pretty whipped after a brewday, but not from strain in lugging equipment around. My knees are pretty terrible and I feel it after standing on my feet for hours on end. I keep in shape, eat reasonably well and run at least a mile every day (started over two years ago, gotta keep the streak going!), but I still feel it at the end of the day. The fact that I usually start around 4am and finish by about 11 probably has something to do with it too.

I do full boil 5 gallon BIAB batches and don't really have to lift much. Someone might get a benefit from it so here's what I do:

The morning before I dump all of my strike water into the kettle on the stove and heat it up the next morning. The grain goes into the big kettle and I mash without having to move anything.

After the mash I slowly lift the bag out and throw it (while it's still saturated) into a smaller kettle and add sparge water (boiled in a small stock pot) to make up some volume. In the mean time the big kettle goes out to the burner (considerably lighter with no grain and less water). After the dunk sparge I remove the grain and it goes into a colander to let the last bit drain while the kettle comes up to a boil. The 5 gallon kettle with the sparge water goes and gets dumped into the big kettle.

Until the end of the boil, I never move more than ~4.5 gallons at a time.

I do full boil 5 gallon BIAB batches and don't really have to lift much. Someone might get a benefit from it so here's what I do:

The morning before I dump all of my strike water into the kettle on the stove and heat it up the next morning. The grain goes into the big kettle and I mash without having to move anything.

After the mash I slowly lift the bag out and throw it (while it's still saturated) into a smaller kettle and add sparge water (boiled in a small stock pot) to make up some volume. In the mean time the big kettle goes out to the burner (considerably lighter with no grain and less water). After the dunk sparge I remove the grain and it goes into a colander to let the last bit drain while the kettle comes up to a boil. The 5 gallon kettle with the sparge water goes and gets dumped into the big kettle.

Until the end of the boil, I never move more than ~4.5 gallons at a time.

Lazy person right here. I start the session by pumping ro water into the hlt, mash via recirculation (underletting and using a peristaltic pump seems to have eliminated my need for an initial stir), then I pump to the kettle, and from the kettle to my fermenter(s). I dump the spent grains in my wheel barrow and trundle them off for mulching. The heaviest thing I pick up is a bucket of grain  . I do sometimes go running during the mash or boil though, so that's sometimes tiring/ache inducing.

. I do sometimes go running during the mash or boil though, so that's sometimes tiring/ache inducing.

MaryB

Well-Known Member

Or rig a zip line down the steps and use it to lower the full buckets/carboys! Use mechanical advantage with pulleys!

Get in better shape!

MaryB

Well-Known Member

I brew in my garage, if it is above 20 degrees I can use the outside faucet to run a hose in for wort cooling/cleanup into the driveway(gravel). 3 tier all gravity fed, right now I lift gallon jugs to fill the HLT but it is going to get a sight glass when I get the RO system installed so I can just run the RO hose into it and fill. Even fermenters are filled via gravity, I made sure the BK burner sat high enough to get a 6.5 gallon bucket under it to drain the wort. I pick the bucket up place it in my garden wagon(rated for 500 pounds) and pull it to the house door where I unload onto house planter rollers to roll it to the pantry to ferment. Minimal lifting at all stages! Work smarter not harder!

Gravity fed means less cleanup, one the sparge is done I lift the MT to the floor, scoop grain into 2 buckets to carry to the garden or compost. Rinse/scrub it out while the BK is coming to a boil. Always be cleaning if you are waiting! It shortens the brew day!

11 gallon batches and I have had 9 surgeries on my back, neck, shoulder, wrist, hip, knee, and thumb in the last 9 years! Lumbar decompression to remove bone spurs and chewed disc, I have a 3 inch plate in my neck...

Work smarter not harder!

Gravity fed means less cleanup, one the sparge is done I lift the MT to the floor, scoop grain into 2 buckets to carry to the garden or compost. Rinse/scrub it out while the BK is coming to a boil. Always be cleaning if you are waiting! It shortens the brew day!

11 gallon batches and I have had 9 surgeries on my back, neck, shoulder, wrist, hip, knee, and thumb in the last 9 years! Lumbar decompression to remove bone spurs and chewed disc, I have a 3 inch plate in my neck...

Work smarter not harder!

For those brewing with RO water, I have added a couple things to my system that really help.

I got really tired of filling my 15 gallon HLT over a series of days using the couple of gallons the RO system could produce. I have added a 20 gallon storage/pressure tank for the RO and a booster pump on the input.

I can fill the HLT the night before the brew and by the next day the storage tank is nearly full again so there is plenty of water for sparging , etc. Further, I plumbed the RO water over to the brew bench so filling the HLT is trivial.

The booster pump increases the input water pressure to the RO filter to 125 psi. This not only makes water a lot faster, but it actually makes better water. The membrane does a better job of rejection with the higher pressure.

The system is from Culligan. I lease the whole works so they take care of all the maintenance on the filter cartridges and hardware at no additional cost. To please SWMBO, the RO is also plumbed to the kitchen sink and fridge. Crystal clear ice and cold water at the fridge. Room temp and 190F water at the sink.

I got really tired of filling my 15 gallon HLT over a series of days using the couple of gallons the RO system could produce. I have added a 20 gallon storage/pressure tank for the RO and a booster pump on the input.

I can fill the HLT the night before the brew and by the next day the storage tank is nearly full again so there is plenty of water for sparging , etc. Further, I plumbed the RO water over to the brew bench so filling the HLT is trivial.

The booster pump increases the input water pressure to the RO filter to 125 psi. This not only makes water a lot faster, but it actually makes better water. The membrane does a better job of rejection with the higher pressure.

The system is from Culligan. I lease the whole works so they take care of all the maintenance on the filter cartridges and hardware at no additional cost. To please SWMBO, the RO is also plumbed to the kitchen sink and fridge. Crystal clear ice and cold water at the fridge. Room temp and 190F water at the sink.

Similar threads

- Replies

- 25

- Views

- 2K

- Locked

- Replies

- 9

- Views

- 1K

- Replies

- 13

- Views

- 2K

- Replies

- 7

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)