worlddivides

Well-Known Member

So I've been using my main fermenter for exactly 1 year now (I started using it in July 2024), and I've never really had any problems with it. But today when I added StarSan solution to it, it started leaking from the bottom. Very slowly, but leaking. I tightened the thing you screw on inside, but that didn't work. I disassembled and put it back together, but that didn't work. So I took my second fermenter that I bought last year but never ended up using, but it massively leaked because the spigot had split in half (probably because the closet where I keep it gets up to 110-120F / 45C-50C in the summer here in Japan). So I poured the solution into my bottling bucket, which did not leak and then took the spigot from my main fermenter and moved it to my secondary fermenter. Nope, the secondary fermenter also leaks with that spigot. I tried various different versions before going back to the original crappy spigot that the fermenter came with. Nope, that leaks even more. At this point, my wort had cooled down to the low 70s F (mid 20s C) and I felt I should just give up. So I poured the wort into my bottling bucket, drilled a hole in the bottling bucket's lid to fit my temperature well and airlock, pitched the yeast, and hooked it up to a controller.

The only reason I can think for my fermenters just suddenly starting to leak after a year of not leaking is the massive heat (95F-100F outdoors, 95-100F on the first floor with the AC off, 100-105F on the second floor with the AC off, and 100F-120F on the third floor with the AC off). I normally only have the AC on when I'm in a room, my wife's in a room, or my cats are. The third floor is where I store most things (there just isn't room on the first or second), but the only fermenter I always keep on the first floor is my main fermenter. That said, it was pretty hot last month and I fermented a lager, but it didn't leak at all. So maybe it isn't the heat?

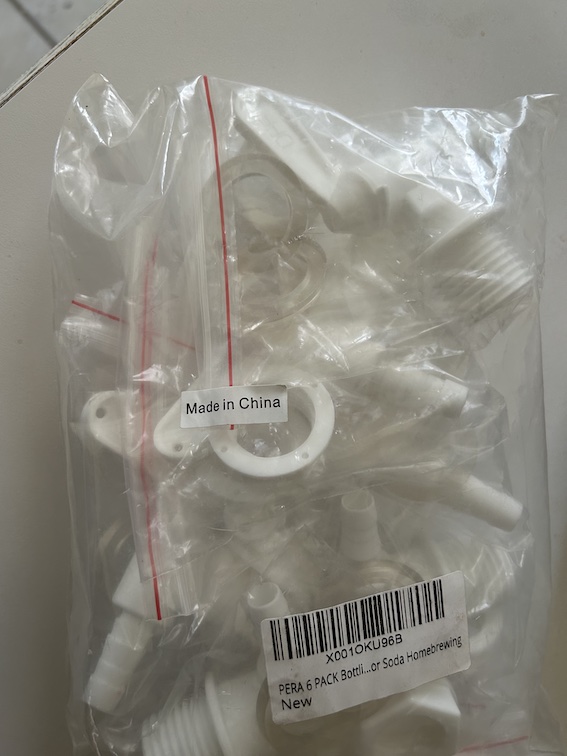

Anyway, I'd prefer to not have to throw away both of these fermenters if I can avoid it, but I can't think of a way to seal them other than what the spigots already have in their design to seal them (the rubber inner ring, for example). Any help would be appreciated!

The only reason I can think for my fermenters just suddenly starting to leak after a year of not leaking is the massive heat (95F-100F outdoors, 95-100F on the first floor with the AC off, 100-105F on the second floor with the AC off, and 100F-120F on the third floor with the AC off). I normally only have the AC on when I'm in a room, my wife's in a room, or my cats are. The third floor is where I store most things (there just isn't room on the first or second), but the only fermenter I always keep on the first floor is my main fermenter. That said, it was pretty hot last month and I fermented a lager, but it didn't leak at all. So maybe it isn't the heat?

Anyway, I'd prefer to not have to throw away both of these fermenters if I can avoid it, but I can't think of a way to seal them other than what the spigots already have in their design to seal them (the rubber inner ring, for example). Any help would be appreciated!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)