Tristenbrews

Member

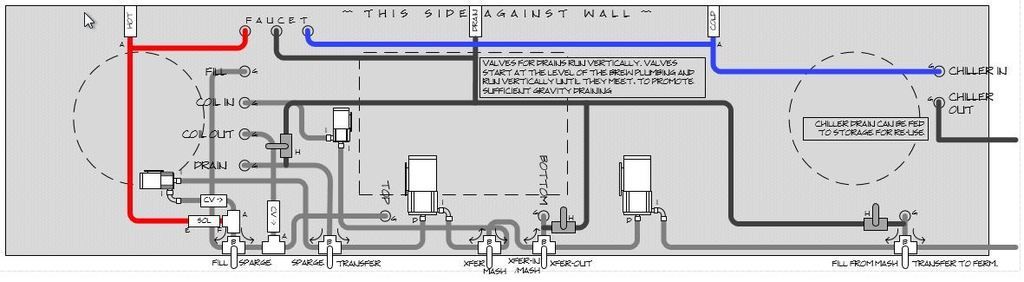

I'm starting to get pieces together to build a 3 vessel, 2 pump, eHerms system. I saw that bargain fittings has a sale (at least I think it's a sale) on 3 pieces ss valves, so I'm thinking about buying up what I need (first official purchase). In my mind, you need a valve whenever liquid is leaving a vessel, and one on the output side of each pump.

So, to me, this means I need 2 for lauter tun (1 out, 1 out for herms coil), 1 for mash tun, and one for boil kettle. Plus 1 for each pump. I see a lot of people putting a valve on every entry and exit point. I'm just trying to do what is logical and functional. I know the savings overall will be small compared to the whole system cost, but still, I'm trying to be frugal about the whole process.

So, to me, this means I need 2 for lauter tun (1 out, 1 out for herms coil), 1 for mash tun, and one for boil kettle. Plus 1 for each pump. I see a lot of people putting a valve on every entry and exit point. I'm just trying to do what is logical and functional. I know the savings overall will be small compared to the whole system cost, but still, I'm trying to be frugal about the whole process.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)