I typically pitch the whole starter right off the stir plate. Recently I have been thinking it might be best to decant to keep extract flavouring out of the wort.

Do you chill after 24 hours on a stir plate, decant, and let it free rise up to pitch temps? Any recommendations are appreciated.

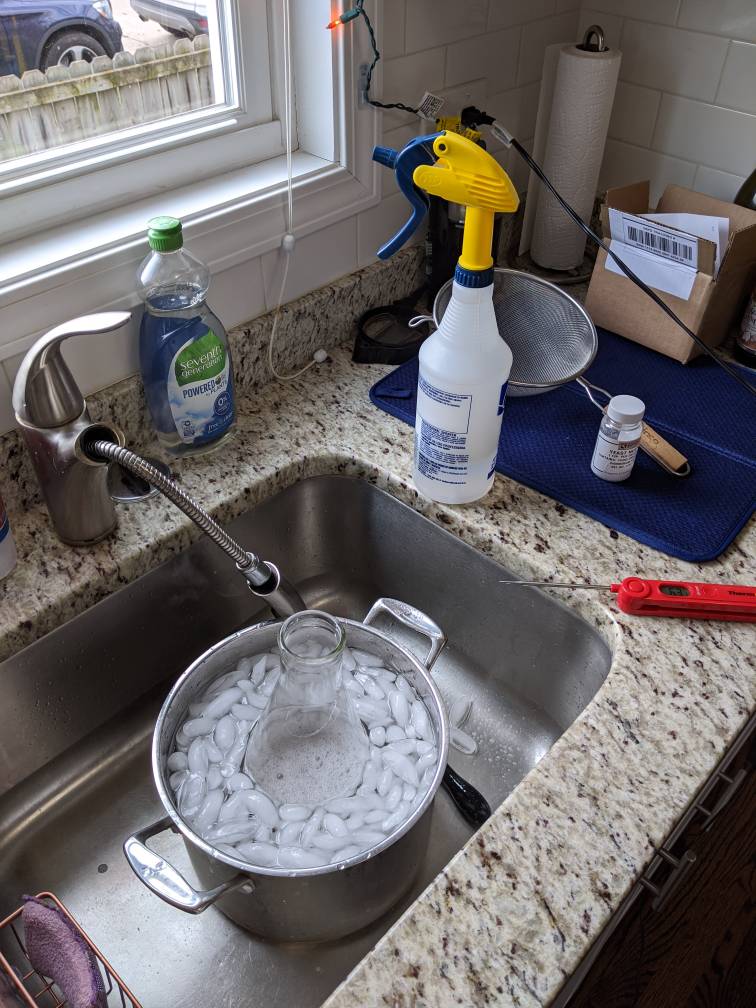

Making a starter at the moment actually. [emoji481]

Do you chill after 24 hours on a stir plate, decant, and let it free rise up to pitch temps? Any recommendations are appreciated.

Making a starter at the moment actually. [emoji481]

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)