storytyme

Well-Known Member

- Joined

- Jun 28, 2012

- Messages

- 390

- Reaction score

- 62

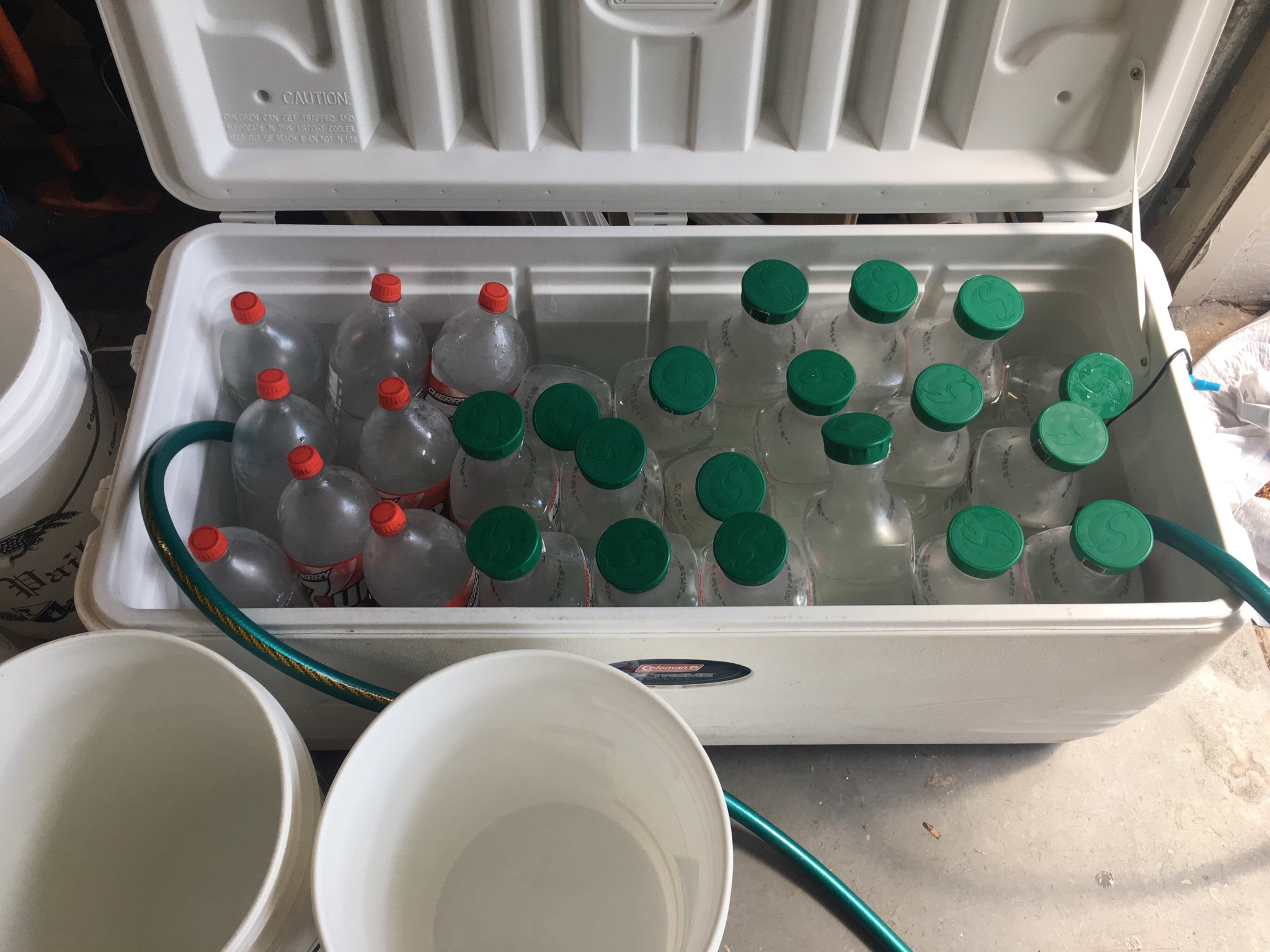

So I splurged and went and got the Blichmann Therminator. I've used it for a few batches and I really like it, but I am thinking I can be more efficient with it. I run my hose throw a ice chest full of ice water then into the plate chiller. It still doesn't seem to get it as low as the water temp even when it is throttled way down. So I was thinking since I am recirculating the wort the last 15 min of the boil to sanitize the chiller why not continue that with the flame out and the hose turned on to create a whirlpool and then once the wort is at a low temp I can transfer to the carboy. Is this what everyone does? Should I not do this? Any other ideas from the plate chiller experts out there please chime in. Thanks in advance everyone.