suitbrewing

Well-Known Member

Greetings to the group and happy new brewing year to all!!!

I am trying to understand why I ended up with Diacetyl in my IPL!

The beer

This is a beer with a 90% pilsner malt and 10% carapils mashed at 65c (single infusion) for one hour and boiled for 90 minutes.

OG: 1.052

Fermentation

Fermented using 2 sachets of rehydrated M76. Yeast packs were reasonably fresh.

The wort was aerated for 1:30 minutes using pure oxygen through an aeration stone before pitching.

I pitched @ 9C and let the wort rise to 11c over the first couple of days naturally.

After the first week or so I increased temps to 13-14 to complete attenuation.

Finally the beer spend 4 days at 16c (diacetyl rest).

During the diacetyl rest I added dry hops in a hop sock which were removed using a stainless steel rod 4 days later.

Final gravity was 1.010

The beer was conditioned at 12C for another week and cold crushed at 3c for kegging.

The diacetyl flavor seems to have developed a week after kegging.

Oxygen exposure

My beer was exposed to oxygen at three points in time – Opened fermentor to drop dry hops – Opened fermentor to spoon out dry hops – transfer of been from fermentor to keg using siphon.

The question

All thoughts welcome!!!

Did I leave the diacetyl rest for too late when the yeast was already dormant???

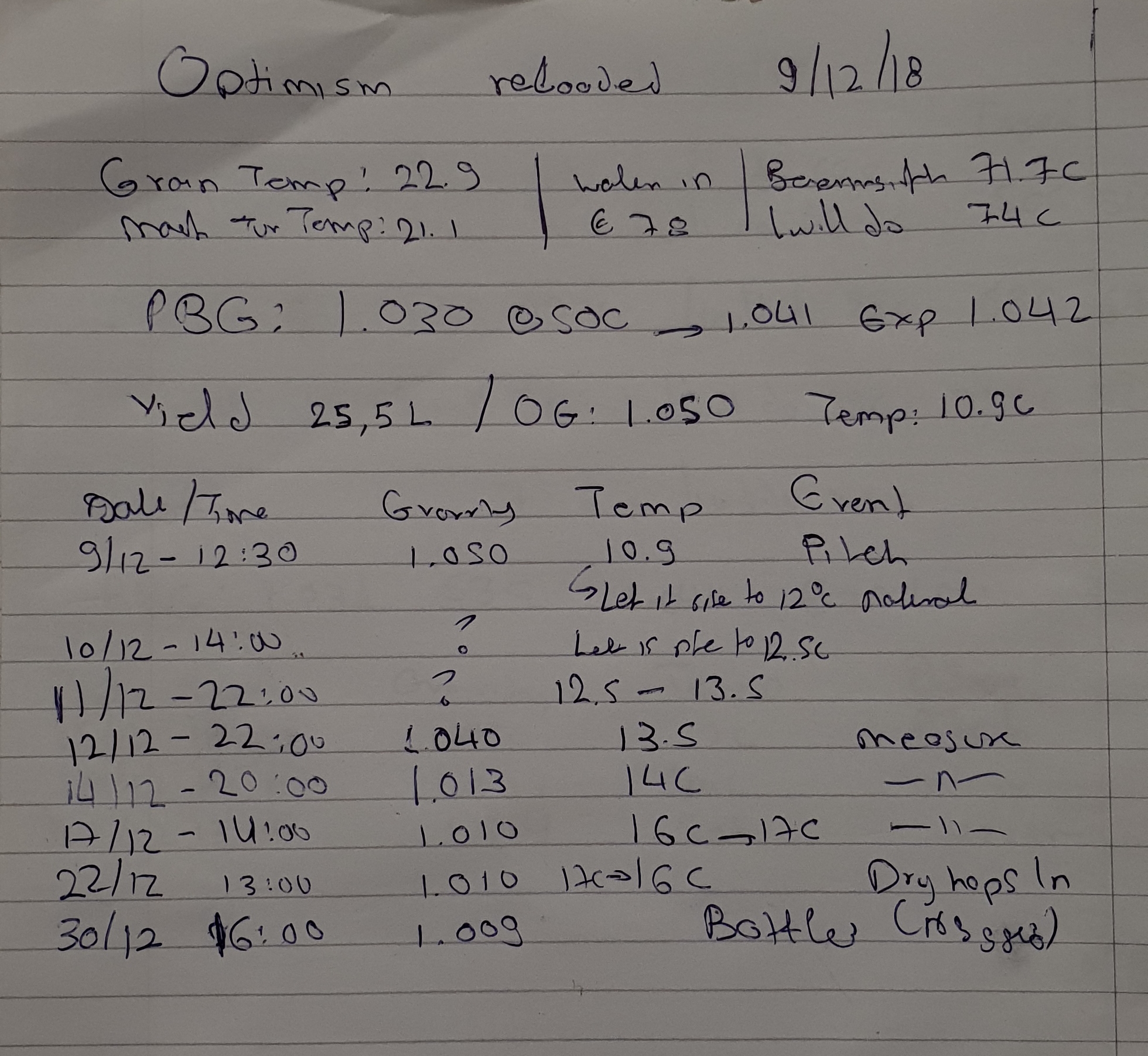

Happy to share more detailed fermentation schedule.

I am trying to understand why I ended up with Diacetyl in my IPL!

The beer

This is a beer with a 90% pilsner malt and 10% carapils mashed at 65c (single infusion) for one hour and boiled for 90 minutes.

OG: 1.052

Fermentation

Fermented using 2 sachets of rehydrated M76. Yeast packs were reasonably fresh.

The wort was aerated for 1:30 minutes using pure oxygen through an aeration stone before pitching.

I pitched @ 9C and let the wort rise to 11c over the first couple of days naturally.

After the first week or so I increased temps to 13-14 to complete attenuation.

Finally the beer spend 4 days at 16c (diacetyl rest).

During the diacetyl rest I added dry hops in a hop sock which were removed using a stainless steel rod 4 days later.

Final gravity was 1.010

The beer was conditioned at 12C for another week and cold crushed at 3c for kegging.

The diacetyl flavor seems to have developed a week after kegging.

Oxygen exposure

My beer was exposed to oxygen at three points in time – Opened fermentor to drop dry hops – Opened fermentor to spoon out dry hops – transfer of been from fermentor to keg using siphon.

The question

All thoughts welcome!!!

Did I leave the diacetyl rest for too late when the yeast was already dormant???

Happy to share more detailed fermentation schedule.