Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 495

- Reaction score

- 575

Mine was around 2.75" as well. I just managed to get it on there just right so that the clamp would go on. Since I won't be brewing for a while, it may be a good idea to grind it down.

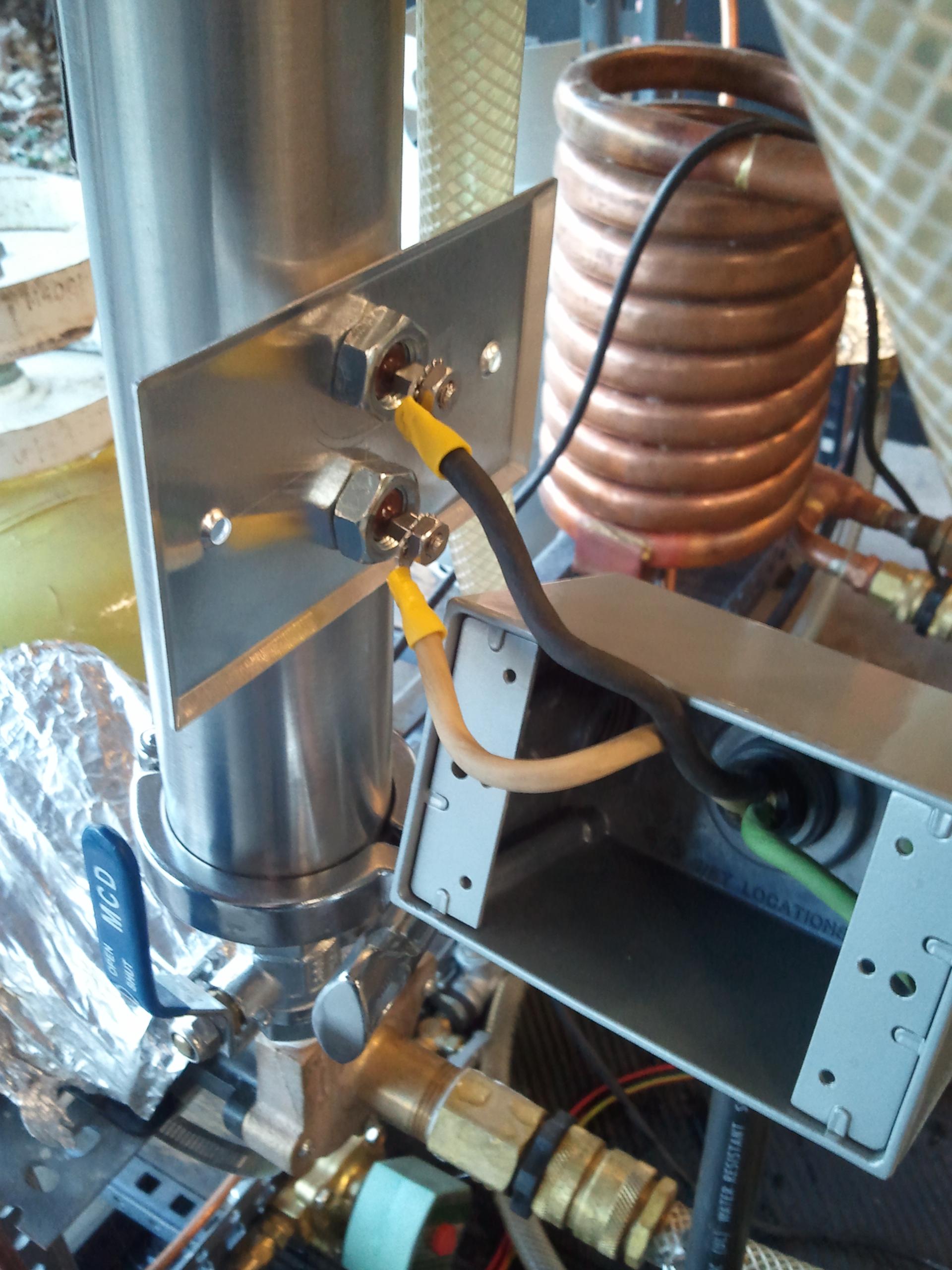

As for the temperature probe... the pressure probe taps are 1/8" NPT. Auber makes an 1/8" RTD probe that will fit in the port... assuming you have a port that clears the element on your tube. This was also a reason why I went with the universal replacement tube, more ports.

The pressure sensor you have there looks like a diaphragm that pushes a rod to open/close a microswitch. Could possibly (depending on how much pressure it needs to trip) be used to prevent the element from going unless the pump was pumping. Just a thought.

Other than the slight oversize on the flange, you can see why this would make an awesome rims tube. When I get a stand built and move to my keggles / keg MLT, I'm going to have the rims tube vertical beside the mash tun, and never worry about air pockets in the tube again.

As for the temperature probe... the pressure probe taps are 1/8" NPT. Auber makes an 1/8" RTD probe that will fit in the port... assuming you have a port that clears the element on your tube. This was also a reason why I went with the universal replacement tube, more ports.

The pressure sensor you have there looks like a diaphragm that pushes a rod to open/close a microswitch. Could possibly (depending on how much pressure it needs to trip) be used to prevent the element from going unless the pump was pumping. Just a thought.

Other than the slight oversize on the flange, you can see why this would make an awesome rims tube. When I get a stand built and move to my keggles / keg MLT, I'm going to have the rims tube vertical beside the mash tun, and never worry about air pockets in the tube again.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)