marcb

Well-Known Member

CoalCracker said:Phew, Hate to see your electric bill haha.

Lol. What do you think the electricity cost is per batch on your system?

CoalCracker said:Phew, Hate to see your electric bill haha.

Phew, Hate to see your electric bill haha.

CoalCracker said:I think I calculated mine out to a little over 4 bucks a brew. I'm going off the cuff as I don't remember 100%.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

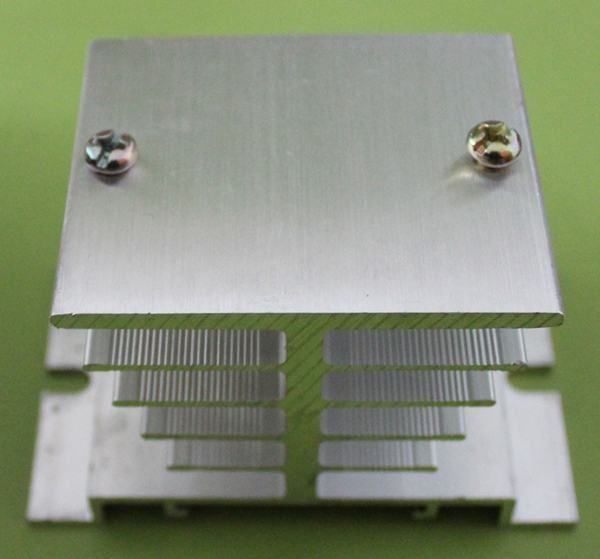

Can you explain further with your comment? Placing the ssr on a din mounted heatsink should be no problem as long as you panel isn't jam packed with other stuff.

The life span of a SSR is directly related to how hot it gets. If its handling a large amount of current, its needs a proper heat sink and thermal paste.

Stolen from a SSRs manufator

Heatsinks are used to create a method of removing heat away from the relay, thus allowing higher current operation. Adequate heat sinks, including consideration of air temperature and air flow, are essential to the proper operation of a solid state relay (SSR, SCR, thyristor or IGBT package). It is necessary that the user provide an effective means of removing heat from the package. The importance of using a proper heat sink cannot be overstressed, since it directly affects the maximum usable load current and/or maximum allowable ambient temperature. Lack of attention to this detail can result in improper switching (lockup) or even total destruction of the solid state relay. Up to 90% of the problems with solid state relays are directly related to heat. POWER-IO has created several customer-specific heatsink designs where overall size, fin geometry, fin angle / spacing, and draw-down geometry were optimized.

Sorry for the slow reply.

Sock said:The life span of a SSR is directly related to how hot it gets. If its handling a large amount of current, its needs a proper heat sink and thermal paste.

Stolen from a SSRs manufator

Heatsinks are used to create a method of removing heat away from the relay, thus allowing higher current operation. Adequate heat sinks, including consideration of air temperature and air flow, are essential to the proper operation of a solid state relay (SSR, SCR, thyristor or IGBT package). It is necessary that the user provide an effective means of removing heat from the package. The importance of using a proper heat sink cannot be overstressed, since it directly affects the maximum usable load current and/or maximum allowable ambient temperature. Lack of attention to this detail can result in improper switching (lockup) or even total destruction of the solid state relay. Up to 90% of the problems with solid state relays are directly related to heat. POWER-IO has created several customer-specific heatsink designs where overall size, fin geometry, fin angle / spacing, and draw-down geometry were optimized.

Sorry for the slow reply.

Would one not expect that the supplied DIN mounted heat sink for the SSR should be designed to allow correct operation of the SSR. A big factor would also to not max out your SSR, go for a 40A for a 20A load. I have one 40A SSR mounted on a DIN heatsink inside my box, under load the back of the box is barely warm to the touch.

As long as you have a heat sink to mount to the SSRs, you're good. If you mount a SSR to some DIN rail, it isn't going to last a long time. Switching a 20amp load is a lot of energy... that creates alot of heat, it needs to go somewhere.

mattd2 said:Ahh, I understand where you are coming from now. I think due to the photo angle you can't actually see that it looks like he has the SSR mounted to these heatsinks which are then attached to the DIN rail

The brew kettles arrived today from Mass less than a week after being sent! Thanks again Doug. These will work perfectly! They need to go off to the sanitary welder to get two ferrules each for elements, one each for thermowells and outlet valve and a tangential inlet for whirlpooling! More pics later today when I pick up the remaining two tables from the welding shop.

Where are these kettles from?

mattd2 said:Marcb, with the DIN mounted heatsinks do you have to slide them on from the end before mounting the din rail or can you snap them on?

Better angle?

Sub.

Sub.marcb said:So at 5x that I'm even with a 20lb propane tank fill.... Given that I'll be using a NG tankless I'm guessing it will be even less as I won't be heating strike/sparge water

Carlscan26 said:What's your gas rate vs your electricity? If its cheaper to run electric for the boil it would be so for the sparge etc. Around here though gas is cheaper than electricity.

Do you have a detatched garage? I was under the impression you can't get any kind of brewery licensed if it's attached to a residence?

marcb said:Getting the garage cleaned out, checking out the kettle layout.

Carlscan26 said:Four vessel?

marcb said:Two mash, two boil kettle and a tankless for strike and sparge.....

Hoping to squeeze 40-45 out of each kettle for an 80-90g brew day

Dukeman9988 said:At what rate does the tankless spit out 170degree water?

marcb said:I'm going with a rinnai condensing unit that does 9.8 GPM at 45 degree rise. Max flow rate at 170 will be ~4-5gpm. Within 15 minutes I will be mashing in both tuns. Rinnai also has a very low activation flow rate which makes it ideal for an automated sparge system with a float switch.... I am also designing an automated valve setup that has a thermometer and will divert tankless output to a recirc loop if it is below the set point. This will keep me from getting any lukewarm water during the auto sparge.

What's your gas rate vs your electricity? If its cheaper to run electric for the boil it would be so for the sparge etc. Around here though gas is cheaper than electricity.

Do you have a detatched garage? I was under the impression you can't get any kind of brewery licensed if it's attached to a residence?