jekeane

Well-Known Member

Backstory: I purchased a used panel and it didn't turn out well. I found several major issues when I more closely inspected the panel at home.

I had to replace SSR's and the boil kettle l6 outlet as well as the wires to the outlet. While replacing the SSR's I also upgraded the heatsink.

My problem is now the Boil Kettle still wont fire. I have tried swapping cables and a different element and it isnt anything as simple as that I assume.

Some observations:

1. When I have nothing hooked up and switch to the BK the light turns on and stays on.

2. When I hook everything up and turn the system on the SSR that leads to the HLT (which works turns solid red) However the SSR that leads to the boil kettle does not turn on.

Boil Kettle pid is a auberin. The HLT and MT are Mypin

When I switch the element selector to the BK it faintly flashes, if you blink you would miss it but that is all. Im at a loss at this point. I am pretty out of my element with the panel stuff I can follow directions but of course a second hand custom panel lacks those...

what do i need to do next?

Old SSR and heatsink beside the new ones I just installed. Purchased from Auberins.

Outside panel

Inside front panel bottom right is the bk light

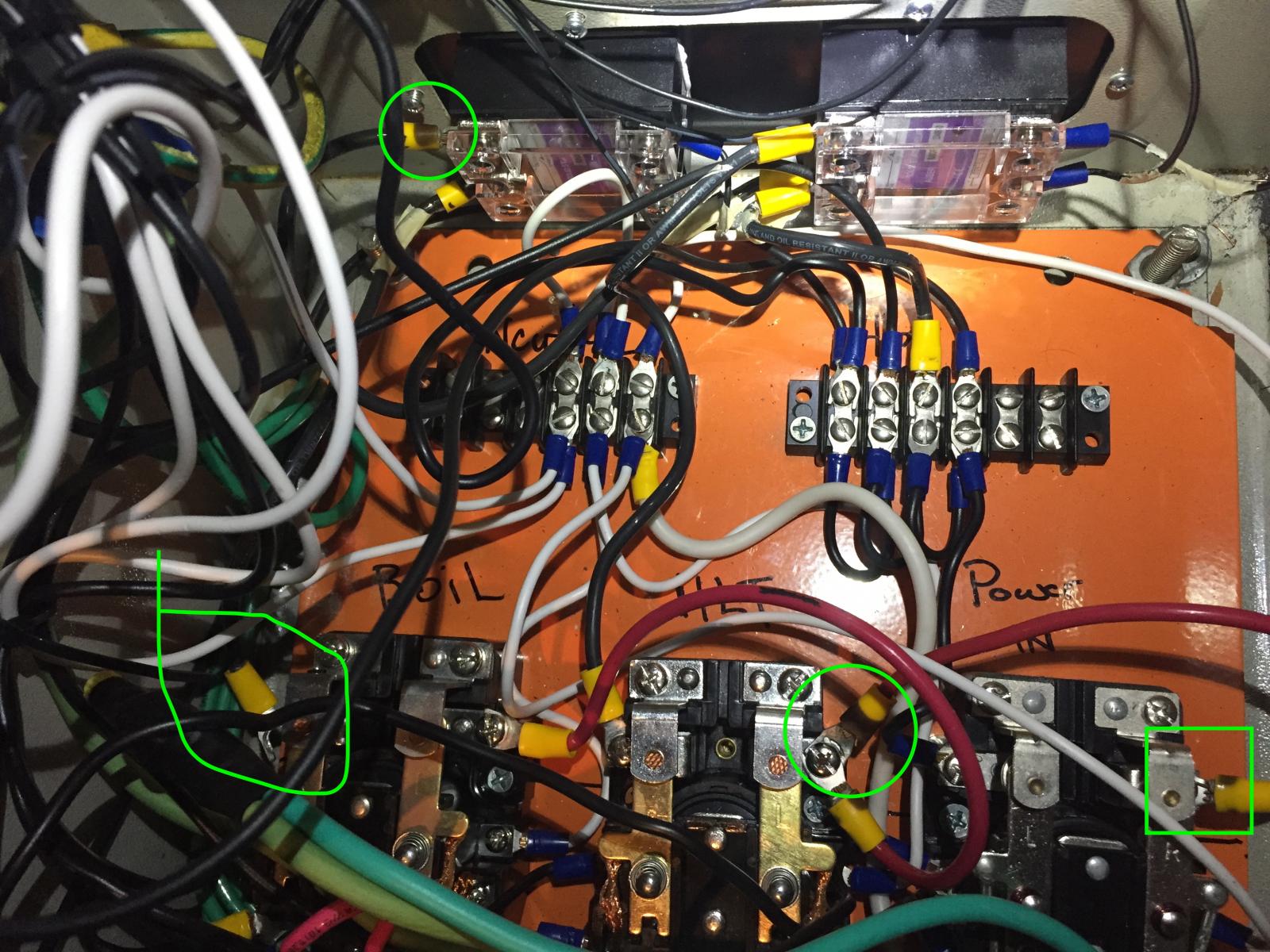

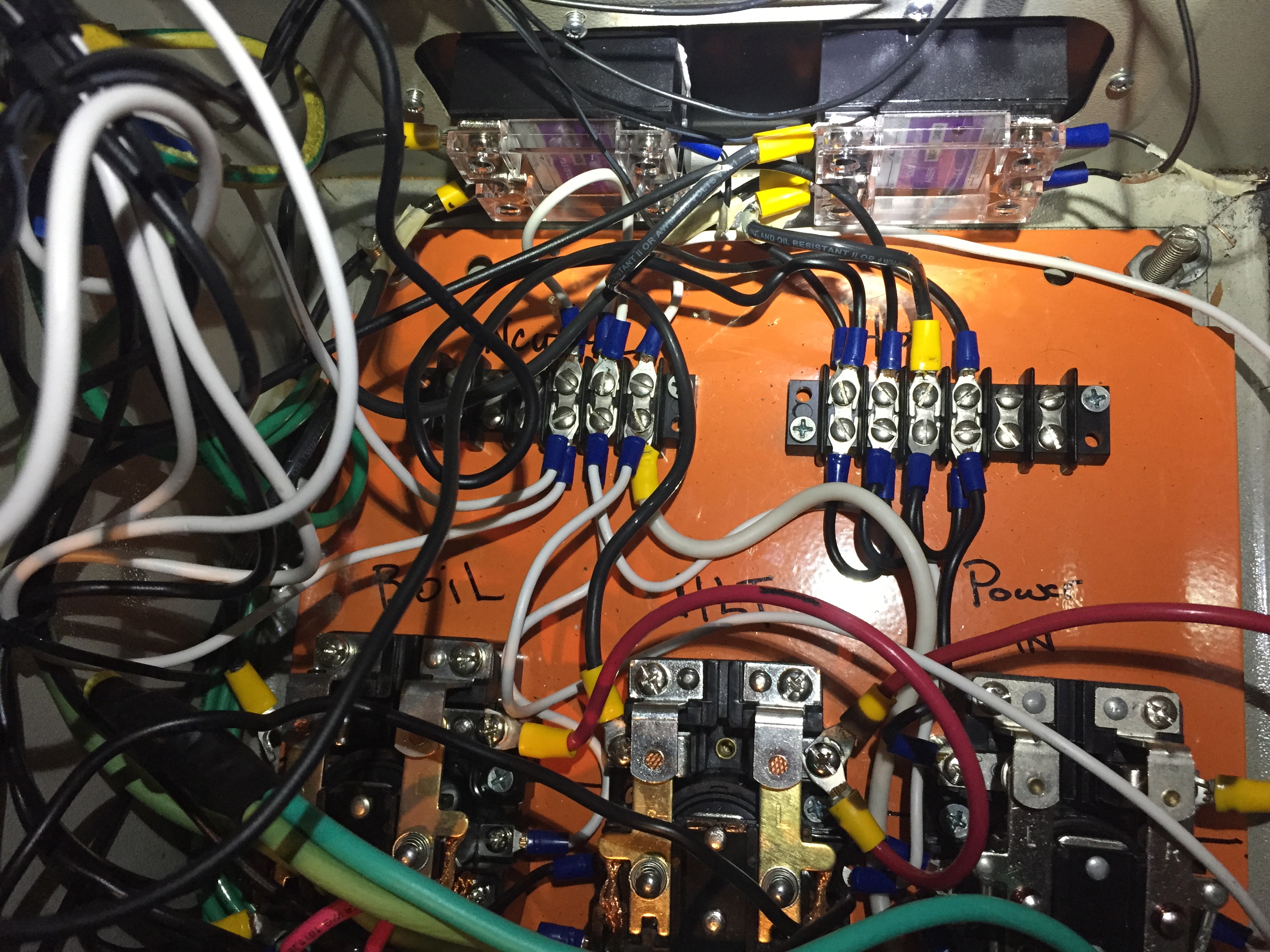

inside case

I had to replace SSR's and the boil kettle l6 outlet as well as the wires to the outlet. While replacing the SSR's I also upgraded the heatsink.

My problem is now the Boil Kettle still wont fire. I have tried swapping cables and a different element and it isnt anything as simple as that I assume.

Some observations:

1. When I have nothing hooked up and switch to the BK the light turns on and stays on.

2. When I hook everything up and turn the system on the SSR that leads to the HLT (which works turns solid red) However the SSR that leads to the boil kettle does not turn on.

Boil Kettle pid is a auberin. The HLT and MT are Mypin

When I switch the element selector to the BK it faintly flashes, if you blink you would miss it but that is all. Im at a loss at this point. I am pretty out of my element with the panel stuff I can follow directions but of course a second hand custom panel lacks those...

what do i need to do next?

Old SSR and heatsink beside the new ones I just installed. Purchased from Auberins.

Outside panel

Inside front panel bottom right is the bk light

inside case

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)