bornandraisedlv

Well-Known Member

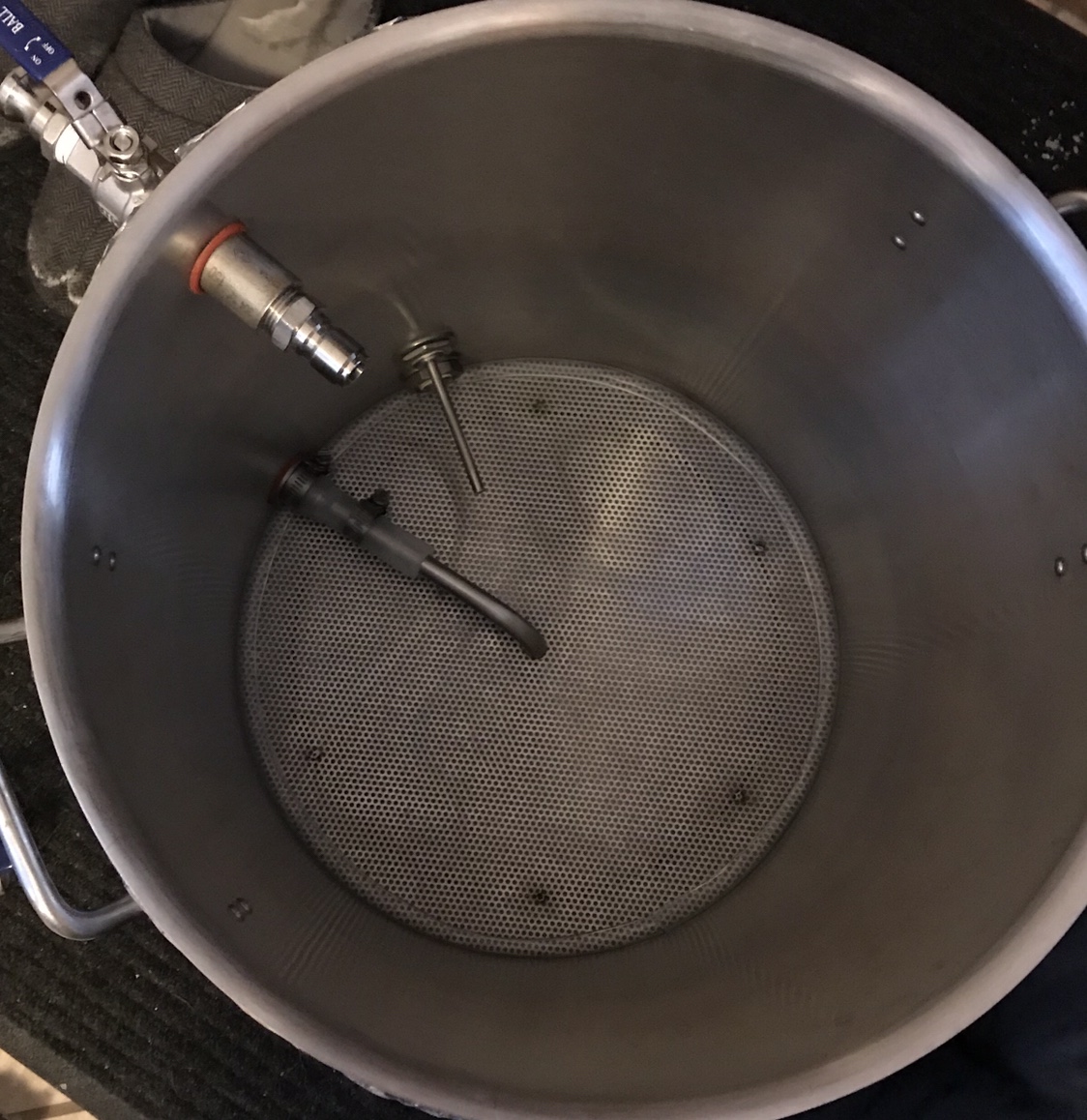

Good catch on the 1/4" fitting. An entire system only flows only as well as its smallest hole. I think you'll be very happy with the results on your next brew. I'm guessing within 5 or 7 minutes your wort is crystal clear and flowing well. I still recommend you leave your mill at .030 to .035. Your efficiency will be rewarded.

This is what I am hoping for. Oh also in regard to gap size on my mill I am not going to touch it for now. It’s set where NorCal says to set it, should be fine once I fixe the side wall gap.

Thanks again for all of the advice and input!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)