I'm ok with some basic electrical, which this probably is lol, but I still don't quite understand how to do it and I'm hoping maybe you can point me in the right direction. I am working on a new panel and for simplicity say I've got one PID that controls one element. I need to be able to via a selector switch choose between using the PID's call for the element to be on, to bypass the PID and turn it manually on, or to be able to totally turn the element off and no matter if the PID calls for it to be on or off it stays off. And ideally, I need an indicator light to light anytime it's on. I'm sure I'm overthinking this but little help?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with wiring switch for using PID or manual on/off for element

- Thread starter jcaudill

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Why do you think you need to be able to bypass the PID and have the element on full power?

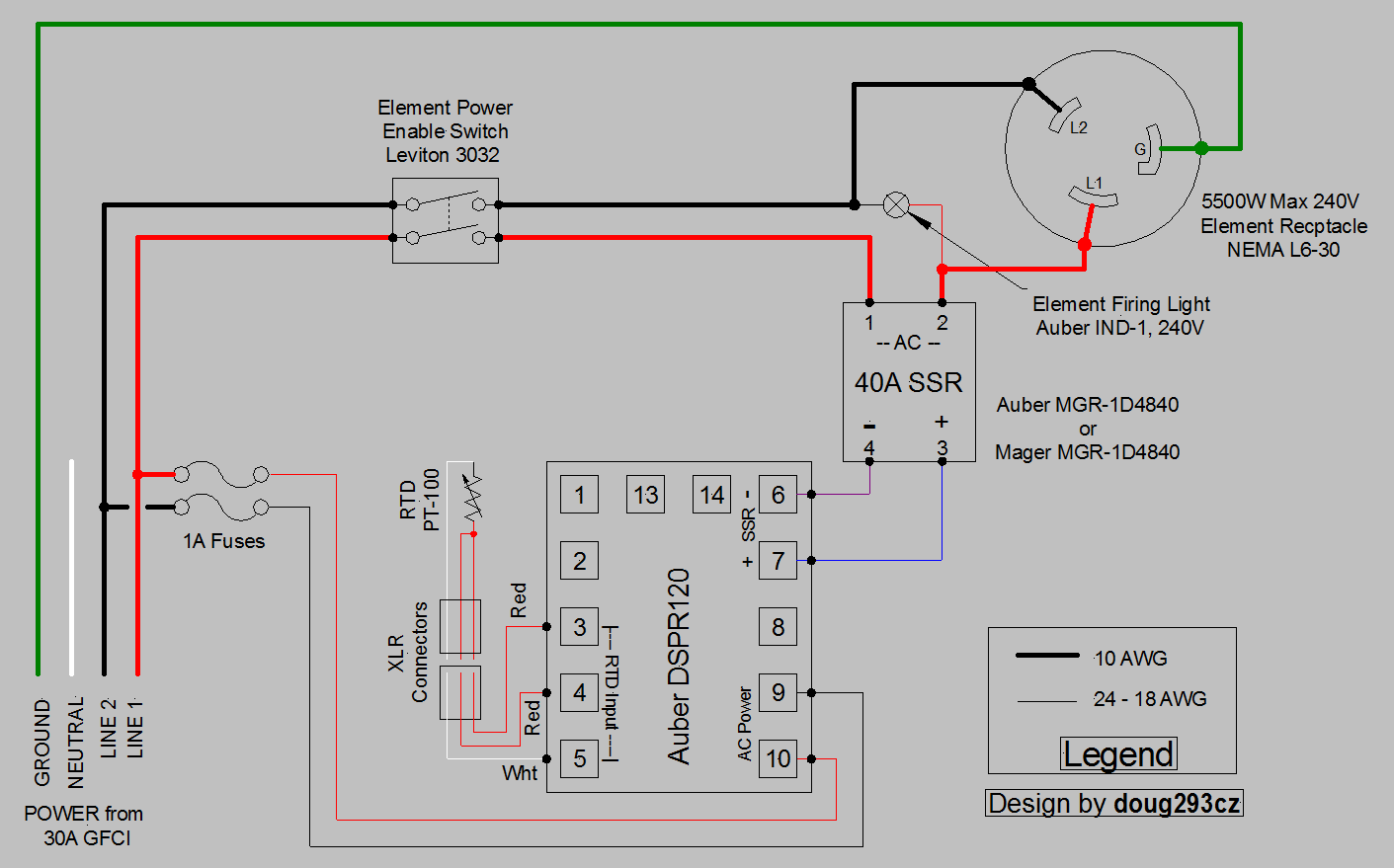

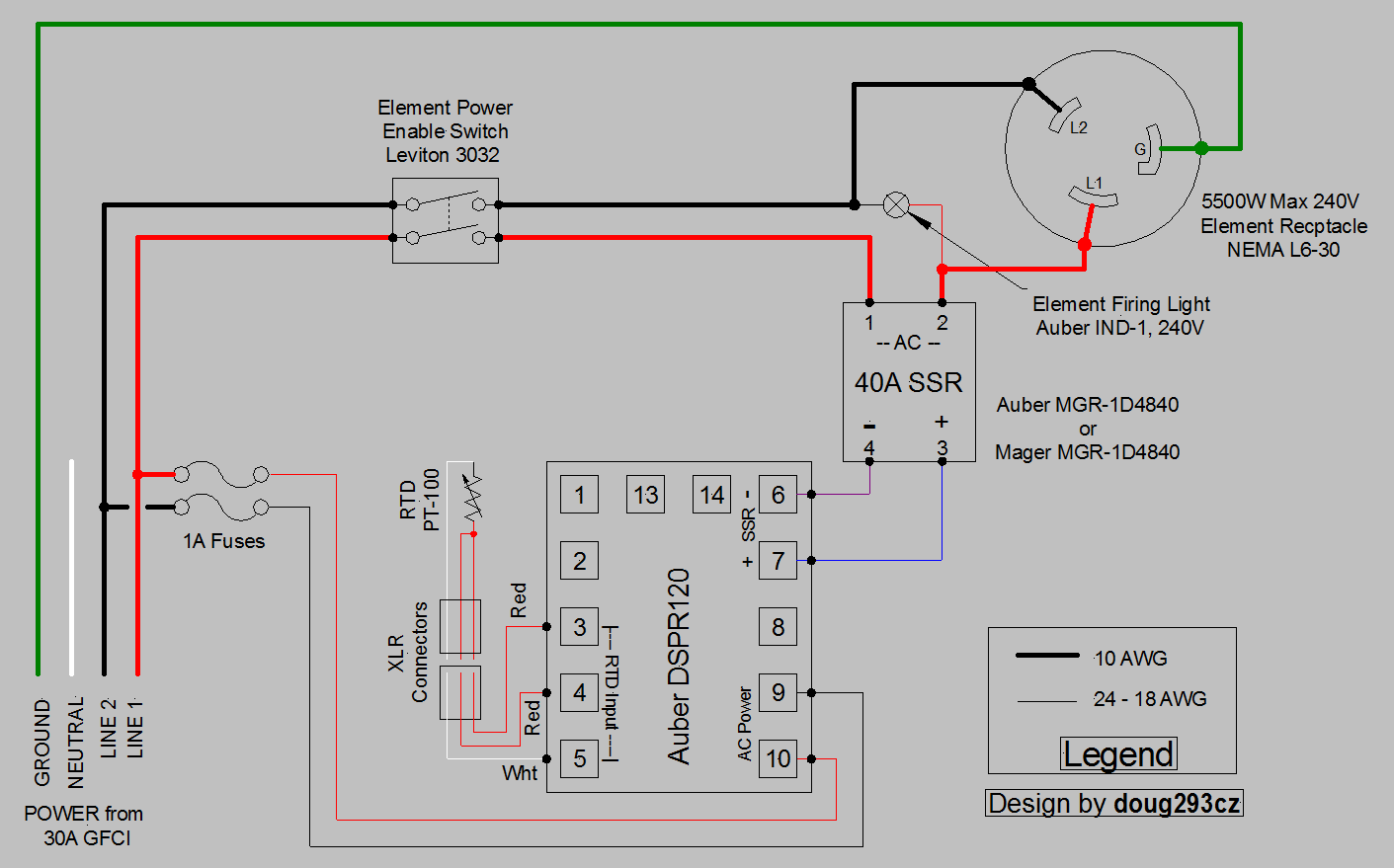

Here's a basic controller schematic that does what needs to be done.

Brew on

Here's a basic controller schematic that does what needs to be done.

Brew on

jcaudill

Well-Known Member

I don't have a good reason other than I prefer to have manual control of elements from time-to-time. For example I just want to heat water and don't care what the temp is. Or say I lose a PID in process - if I can switch over to manual I'm not dead in the water. I definitely under the diagram below - I just don't know how it changes for this particular requirement. Thank you BTW!

Why do you think you need to be able to bypass the PID and have the element on full power?

Here's a basic controller schematic that does what needs to be done.

View attachment 684232

Brew on

Trying to manually control an element to maintain a temperature, or even a steady boil vigor, is just about impossible. You'll be flipping the switch on/off every couple of seconds (this is what the PID's do to control temp/power level.) To heat water manually, just set the EZBoil to boil mode, and it will heat at max power until just before boil is reached. With a generic PID, just put it in manual mode at 100% power, and it will heat water as fast as possible.I don't have a good reason other than I prefer to have manual control of elements from time-to-time. For example I just want to heat water and don't care what the temp is. Or say I lose a PID in process - if I can switch over to manual I'm not dead in the water. I definitely under the diagram below - I just don't know how it changes for this particular requirement. Thank you BTW!

Brew on

Not to pile on, but that particular function is already built in to all PIDs though. If you want the element on for an undetermined period of time, just set the SV to 213F if it doesn't have a manual/pwm mode. If it does have a manual mode, set it to 100%.

For practical purposes, you always do have a temperature in mind and you might as well let the controller do its thing.

All that said, "element enable/disable" uses either a 30amp 2-pole contactor or a heavy duty toggle switch on both hot legs.

To force the element on, essentially bypassing the PID/SSR control, you can choose two methods. Install a small 12DVC adapter inside the box and run it through a switch that ultimately hits the SSR control terminal (faking the control the PID would send). The other option is to run a contactor in parallel with the SSR.

I really don't think it's worth it since you can get the latter function on the controller. Good I said it one last time.

You can use a selector switch that is ON/OFF/ON with center maintain and NO contacts on each ON position. Left On can be element enable PID control and Right ON can be element force on.

For practical purposes, you always do have a temperature in mind and you might as well let the controller do its thing.

All that said, "element enable/disable" uses either a 30amp 2-pole contactor or a heavy duty toggle switch on both hot legs.

To force the element on, essentially bypassing the PID/SSR control, you can choose two methods. Install a small 12DVC adapter inside the box and run it through a switch that ultimately hits the SSR control terminal (faking the control the PID would send). The other option is to run a contactor in parallel with the SSR.

I really don't think it's worth it since you can get the latter function on the controller. Good I said it one last time.

You can use a selector switch that is ON/OFF/ON with center maintain and NO contacts on each ON position. Left On can be element enable PID control and Right ON can be element force on.

Bobby's right on the selector switch. However, the PID uses 12vdc to turn the SSR on but the 5500 240vac uses 240 vac and draws approximately 23 amps. I think that's a bit much to expect out of a small switch. So you'll need a dedicated 12 vdc source. I hope I'm not over looking anything. I just got back from excepting my first place award for a Miabock in the Bluebonnet Brew Off. A bit delayed but it was great.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

jcaudill

Well-Known Member

Bobby's right on the selector switch. However, the PID uses 12vdc to turn the SSR on but the 5500 240vac uses 240 vac and draws approximately 23 amps. I think that's a bit much to expect out of a small switch. So you'll need a dedicated 12 vdc source. I hope I'm not over looking anything. I just got back from excepting my first place award for a Miabock in the Bluebonnet Brew Off. A bit delayed but it was great.

Congrats to you! It sounds delicious

I get the feedback on the PID/element. Let's rest that for a second and assume that I'm not trying to control an element but let's say a 24VAC solenoid with a 24VAC PID. This is a bit different than the topic but understanding the concept will help a lot.

Double pole double throw switch. Commons go to solenoid, one set of poles to PID control outputs, other set to 24VAC. This could be implemented with an Auber SW3 (on-off-on) with 4X NO switch blocks.

Brew on

Brew on

jcaudill

Well-Known Member

Double pole double throw switch. Commons go to solenoid, one set of poles to PID control outputs, other set to 24VAC. This could be implemented with an Auber SW3 (on-off-on) with 4X NO switch blocks.

Brew on

Thank you! When you say 4x NO switch blocks, do you mean 2 pairs?

Yes.Thank you! When you say 4x NO switch blocks, do you mean 2 pairs?

Brew on

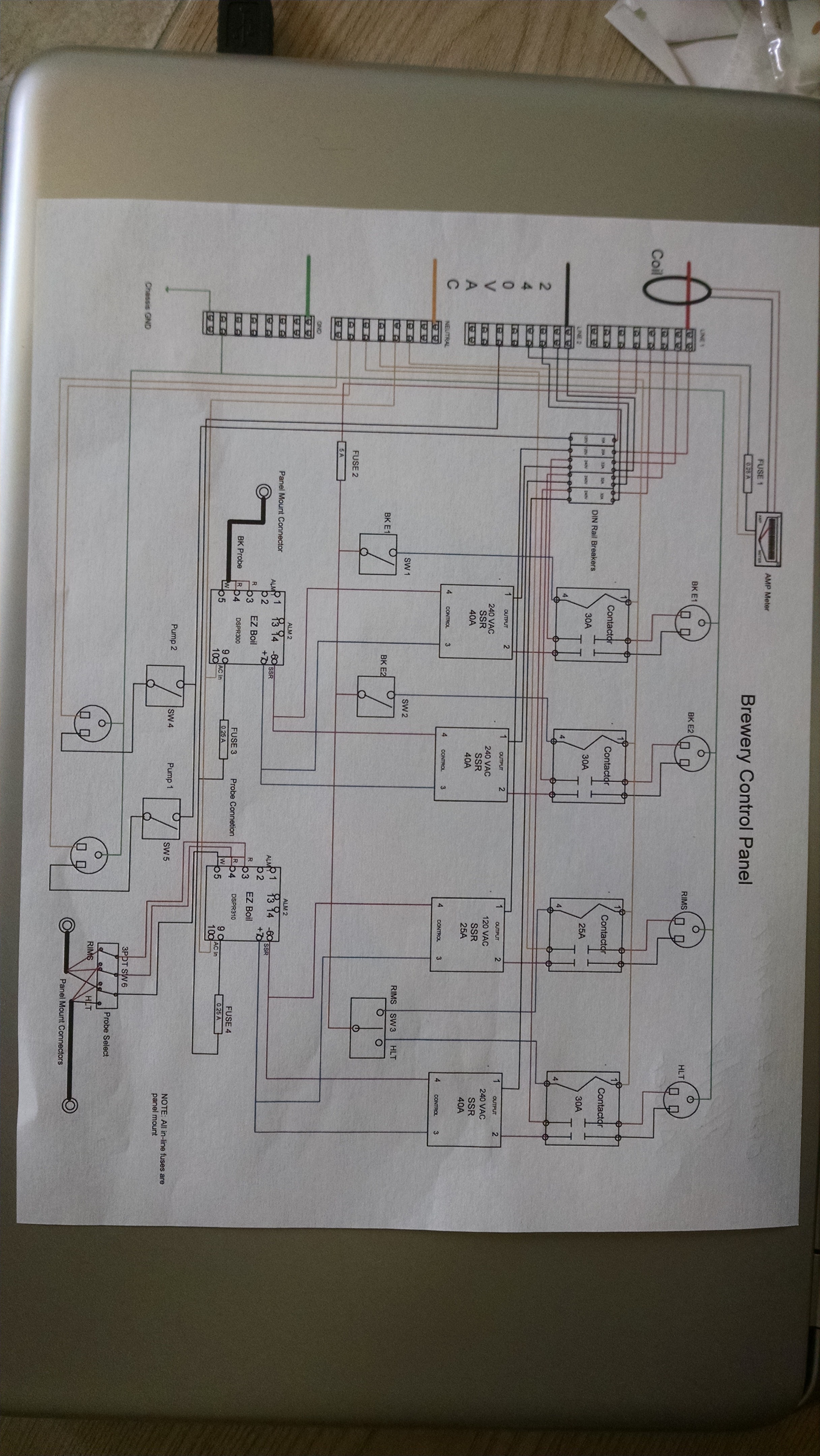

This is the schematic for my control panel maybe you can use part of it. See SW3.Congrats to you! It sounds deliciousGerman beer is harder to find here so I need to get back to brewing!

I get the feedback on the PID/element. Let's rest that for a second and assume that I'm not trying to control an element but let's say a 24VAC solenoid with a 24VAC PID. This is a bit different than the topic but understanding the concept will help a lot.

jcaudill

Well-Known Member

Thank you both for your help! I get it now.

Yes.

Brew on

This is the schematic for my control panel maybe you can use part of it. See SW3.View attachment 684397

Bobby's right on the selector switch. However, the PID uses 12vdc to turn the SSR on but the 5500 240vac uses 240 vac and draws approximately 23 amps. I think that's a bit much to expect out of a small switch. So you'll need a dedicated 12 vdc source.

To be clear, I never suggested that you can run 23 amps through a selector switch. " The other option is to run a contactor in parallel with the SSR. " I should have been specific that the selector switch would be used in tandem with that contactor.

OP is actually driving a 24VAC solenoid, so not high current.To be clear, I never suggested that you can run 23 amps through a selector switch. " The other option is to run a contactor in parallel with the SSR. " I should have been specific that the selector switch would be used in tandem with that contactor.

Brew on

jcaudill

Well-Known Member

All this is great discussion anyhow. I appreciate you all!

jcaudill

Well-Known Member

Go to YouTube and search barley & hops. He has some very easy wiring videos.

I got it sorted thanks!

Similar threads

- Replies

- 20

- Views

- 1K

- Replies

- 11

- Views

- 960

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)