Hello everyone, new to the forum, been brewing for about a year and some change and am moving into kegging!

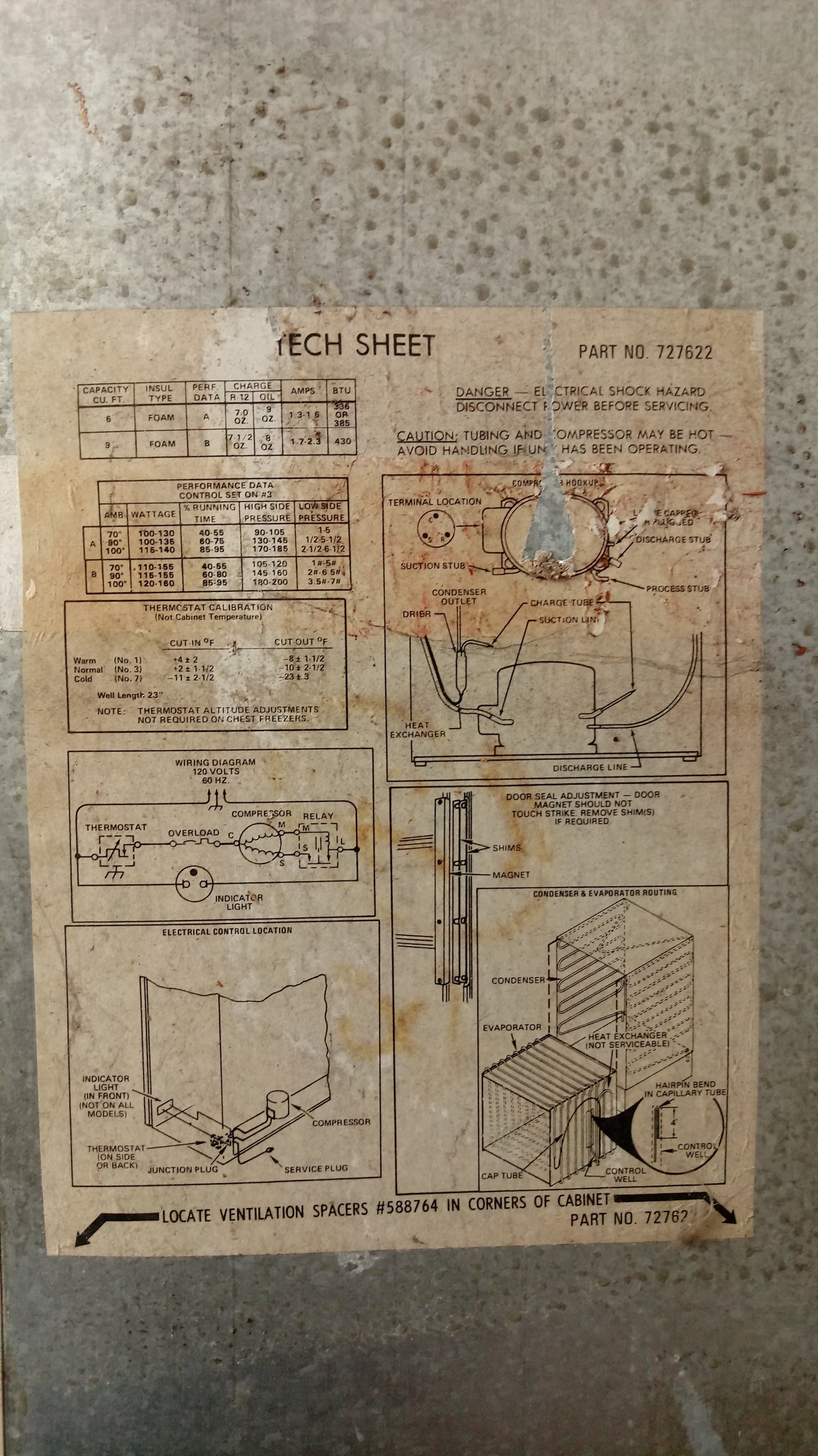

I recently got a decent sized upright freezer, comfortably fits 4 cornies and with some room to play with. I live in a pretty small apartment and due to where the keezer will be the best place to put the taps will be just above the door (on the door might work, but a wall is right next to it, and its only a matter of time before I bash the faucets into the wall while opening). The freezer has a diagram on the back, one picture shows the evaporation lines, the other shows condenser lines. The issue is that I dont undertand this damn thing at all, ive included both an image of the freezer itself and the diagram, the lower right window is the one in question. The condenser diagram is clear and is obviously the freezer, but the evaporator one confuses me.

Its not even the same shape or size as the freezer itself, im not sure if its a different unit (as there is data for two different units on this card) or if its just not to scale, and just meant to show where the lines are regardless of how long they are. I suspect that the latter is the case, and those dashed lines are meant to demonstrate that its just scaled down to fit. If that is the case it doesnt look like its safe to drill anywhere except the very back of the top, the back itself and the door. Got it off craigslist for super cheap and it works just fine, so I wont want to break it!

I recently got a decent sized upright freezer, comfortably fits 4 cornies and with some room to play with. I live in a pretty small apartment and due to where the keezer will be the best place to put the taps will be just above the door (on the door might work, but a wall is right next to it, and its only a matter of time before I bash the faucets into the wall while opening). The freezer has a diagram on the back, one picture shows the evaporation lines, the other shows condenser lines. The issue is that I dont undertand this damn thing at all, ive included both an image of the freezer itself and the diagram, the lower right window is the one in question. The condenser diagram is clear and is obviously the freezer, but the evaporator one confuses me.

Its not even the same shape or size as the freezer itself, im not sure if its a different unit (as there is data for two different units on this card) or if its just not to scale, and just meant to show where the lines are regardless of how long they are. I suspect that the latter is the case, and those dashed lines are meant to demonstrate that its just scaled down to fit. If that is the case it doesnt look like its safe to drill anywhere except the very back of the top, the back itself and the door. Got it off craigslist for super cheap and it works just fine, so I wont want to break it!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)