Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

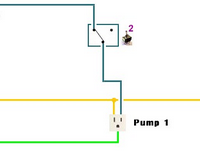

I'm looking at adding a water level sensor in my HLT, to avoid the camco-elements getting fried in case something happens and the water level drops too much so they will be exposed in air.

This is what I've found so far. If it does what I think it does I'll shoot them a mail asking if it's 304 or 316.

http://www.ebay.com/itm/CR-Horizont...548?pt=LH_DefaultDomain_0&hash=item1c3a0f1e0c

I basically want it to shut off the pump connected to the HLT. Do I need anything else than this? A control unit or something similar?

*Edit: Do I understand it correctly if this should be in-line with the pump circuit. If I mount it so the floater drops when the water level doesn't keep it up anymore, the circuit is will break, meaning the pump will not get any power?

This is what I've found so far. If it does what I think it does I'll shoot them a mail asking if it's 304 or 316.

http://www.ebay.com/itm/CR-Horizont...548?pt=LH_DefaultDomain_0&hash=item1c3a0f1e0c

I basically want it to shut off the pump connected to the HLT. Do I need anything else than this? A control unit or something similar?

*Edit: Do I understand it correctly if this should be in-line with the pump circuit. If I mount it so the floater drops when the water level doesn't keep it up anymore, the circuit is will break, meaning the pump will not get any power?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)