arringtonbp

Well-Known Member

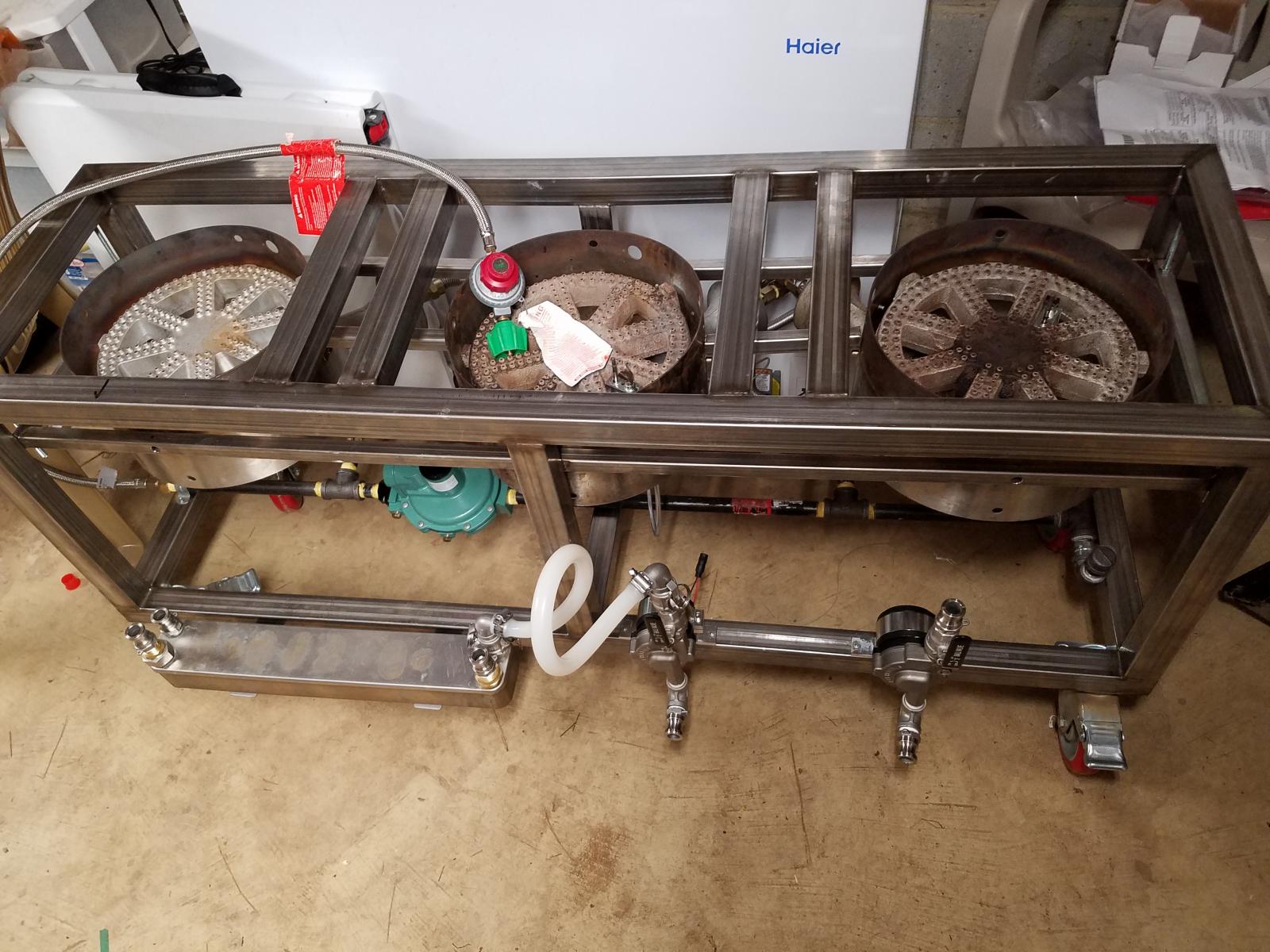

I made a direct fired brutus style brew stand using the honeywell furnace valves. So far. The system seems to work but I am having a hard time troubleshooting the honeywell furnace valves. I'm supplying them with 10.5" wc propane. I finally got the pilot lights adjusted so they are about half blue and half yellow. I really wanted to get them all blue, but by the time I adjust the pilot light low enough to do that, it's not strong enough to keep the thermocouple hot. What is kind of strange is that as soon as the burner kicks in, my pilot light goes to 5 inches tall and completely yellow. The burner flame stays blue with yellow tips. Any ideas for how to troubleshoot this?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)