Hey guys n gals,

So, I'm about to make a big leap up in complexity & process - my first 4 brews were with extracts using starter equipment, but my next one is going to be all-grain and using a 35L Brewzilla I just got delivered.

That's a LOT of 'new' at the same time. I'm really not confident in understanding all the processes for using grain and I'm adding on top of that using new and complicated machinery at the same time. So, I'm going to be posting things here and asking you to check things for me to make sure I'm not making any major screwups, thanks in advance

The main thing I would really love you to check is my brewday checklist - I'm going to write myself a detailed step-by-step brew-day process, it's what i did for my extract & bucket brews and that worked really well for me, no mistakes and 4 great beers, so I will do the same - I don't have that ready yet, I'm still studying up on the process, so I'll post that here later in the thread once I have my first draft.

For now I'd like to check my planned recipe, and confirm that my tap water is useless.

So I'm going to make an Anchor Steam clone. I can get Northern Brewer Hops here in the UK so that's great, but our malts are completely different to US ones so I've had to try and work out substitutions, also the recipe I'm using as my reference ( https://homebrewersassociation.org/homebrew-recipe/anchor-steam-clone/ ) is from 2003 so I'm thinking of substituting the WLP810 in the recipe for saflager 34/70 instead - for higher attenuation and a drier finish.

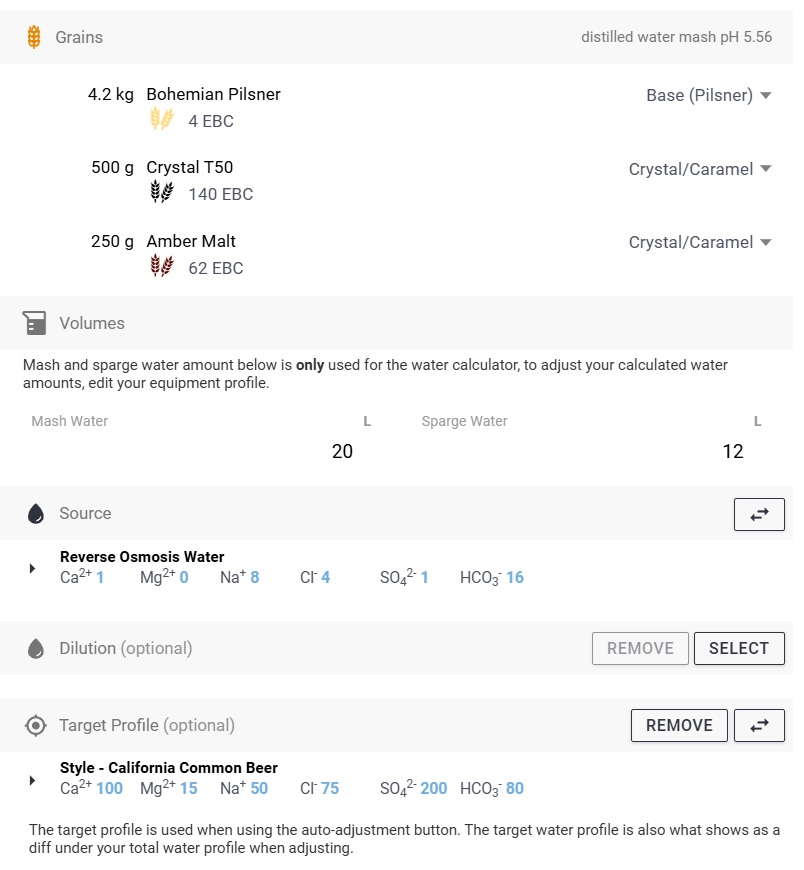

Here's the recipe I've come up with.

4.2KG WeyermannCarapils Extra Pale Premiere Pilsner (edit)

500g Simpsons Crystal T50

250g Simpsons Amber Malt

60 minute mash

60 minute boil

30g Northern Brewer 7.2% @ 60m

25g Northern Brewer 7.,2% @ 20m

Protofloc tablet & yeast nutrient @ 10m

25g Northern Brewer 7.2% @ 0m

Am I OK to use dry yeast (1 pack of 34/70) sprinkled on the top as I've been doing so far, or for this recipe should I do the thing where you add it to some wort for 30 minutes and then pitch it as a liquid?

Sticking all the above into Brewfather and selecting Brewzilla equipment which sets efficiency at 78%, it comes out as follows:

21.6L mash water

11.2L sparge water

pre-boil volume 30L

pre-boil gravity 1.040

post boil volume 25L

post boil gravity 1.045

final gravity 1.007

ABV 5.0%

Next thing is - in another thread Mac recommended these to me as a space-efficient way to make effectively-RO water: https://shop.culligan.co.uk/ and I'm probably going to go with that, but I want to confirm that I'm right in thinking my local tap water is useless to use un-filtered

Putting the numbers from my water report into Brewfather, it comes out as:

7.8pH

Ca2 101 ppm (converted from 252 CACO3)

Mg2 4.2 ppm

Na 24 ppm

Cl 35 ppm

SO4 43 ppm

HCO3 247 ppm

SO4/Cl ratio 1.23

Hardness 269

Alkalinity 202

Residual Alkalinity 128

That's bad, right? There's no real way to adjust that, as it is, to something suitable to brew with? I should get the RO jugs? I could use store-bought spring water which is what I was doing with my extract brews.

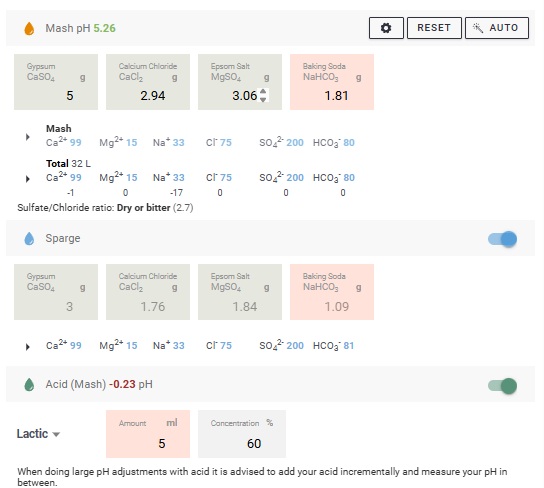

Last question, on the subject of water - when I watch brewing guide videos, they always seem to add the salts to the mash water prior to adding the grain, which confuses me - shouldn't I do it to a combination of mash and sparge water together? if it's in the Mash water only then do I calculate the salts based on the total water volume, meaning the concentration is higher while mashing and then 'waters down' to the desired levels when the sparge water is added? it's the main thing right now that I can't get my head around.

So, I'm about to make a big leap up in complexity & process - my first 4 brews were with extracts using starter equipment, but my next one is going to be all-grain and using a 35L Brewzilla I just got delivered.

That's a LOT of 'new' at the same time. I'm really not confident in understanding all the processes for using grain and I'm adding on top of that using new and complicated machinery at the same time. So, I'm going to be posting things here and asking you to check things for me to make sure I'm not making any major screwups, thanks in advance

The main thing I would really love you to check is my brewday checklist - I'm going to write myself a detailed step-by-step brew-day process, it's what i did for my extract & bucket brews and that worked really well for me, no mistakes and 4 great beers, so I will do the same - I don't have that ready yet, I'm still studying up on the process, so I'll post that here later in the thread once I have my first draft.

For now I'd like to check my planned recipe, and confirm that my tap water is useless.

So I'm going to make an Anchor Steam clone. I can get Northern Brewer Hops here in the UK so that's great, but our malts are completely different to US ones so I've had to try and work out substitutions, also the recipe I'm using as my reference ( https://homebrewersassociation.org/homebrew-recipe/anchor-steam-clone/ ) is from 2003 so I'm thinking of substituting the WLP810 in the recipe for saflager 34/70 instead - for higher attenuation and a drier finish.

Here's the recipe I've come up with.

4.2KG Weyermann

500g Simpsons Crystal T50

250g Simpsons Amber Malt

60 minute mash

60 minute boil

30g Northern Brewer 7.2% @ 60m

25g Northern Brewer 7.,2% @ 20m

Protofloc tablet & yeast nutrient @ 10m

25g Northern Brewer 7.2% @ 0m

Am I OK to use dry yeast (1 pack of 34/70) sprinkled on the top as I've been doing so far, or for this recipe should I do the thing where you add it to some wort for 30 minutes and then pitch it as a liquid?

Sticking all the above into Brewfather and selecting Brewzilla equipment which sets efficiency at 78%, it comes out as follows:

21.6L mash water

11.2L sparge water

pre-boil volume 30L

pre-boil gravity 1.040

post boil volume 25L

post boil gravity 1.045

final gravity 1.007

ABV 5.0%

Next thing is - in another thread Mac recommended these to me as a space-efficient way to make effectively-RO water: https://shop.culligan.co.uk/ and I'm probably going to go with that, but I want to confirm that I'm right in thinking my local tap water is useless to use un-filtered

Putting the numbers from my water report into Brewfather, it comes out as:

7.8pH

Ca2 101 ppm (converted from 252 CACO3)

Mg2 4.2 ppm

Na 24 ppm

Cl 35 ppm

SO4 43 ppm

HCO3 247 ppm

SO4/Cl ratio 1.23

Hardness 269

Alkalinity 202

Residual Alkalinity 128

That's bad, right? There's no real way to adjust that, as it is, to something suitable to brew with? I should get the RO jugs? I could use store-bought spring water which is what I was doing with my extract brews.

Last question, on the subject of water - when I watch brewing guide videos, they always seem to add the salts to the mash water prior to adding the grain, which confuses me - shouldn't I do it to a combination of mash and sparge water together? if it's in the Mash water only then do I calculate the salts based on the total water volume, meaning the concentration is higher while mashing and then 'waters down' to the desired levels when the sparge water is added? it's the main thing right now that I can't get my head around.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)