Finally brewed mine on Saturday. Ended up boiling off way more than I intended for my 10 gallon batch and ended up with 9 gallons from about 12.75 in the kettle. I made an all citra partigyle also, but should have just added that into the kettle in hind site. I was in a rush to get to the homebrew christmas party and could have used a little more time though.

Some notes.

I maxed out capacity of my 10 gallon mash tun around 25 lbs 10 oz. Mashed for an hour at 150-148 then just added the extra grain to total 27 lbs (probably should not have bothered, but oh well). It fit in, but then threw off my temperatures. Total mash time was 90 minutes and I vorlaufed for 10 minutes before sparging. I don't have a pump system. I did add some 170 water to the top to increase the temps before the vorlauf.

Sparged with 170 degree water and ended up with about 12.75 gallons. I think I stopped the runnings at 1.020 and just filled up the mash tun with 170 water and let it sit for a while before draining for the partigyle. Probably still left some sugar behind, but ran out of sparge water. I never bother trying to calculate efficiencies but should at some point.

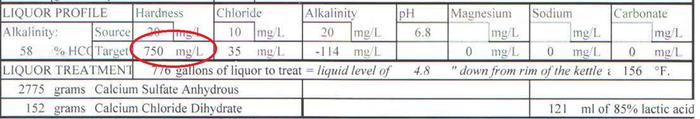

I was too rushed to spend much time trying to calculate water adjustments, but added 4g gypsum and 3.5g CACL to 7 gallons of mash water. I added 1/8 teaspoon of 88% lactic acid to the last 5 gallons of sparge water, but am not sure how much it helped or changed it. Aside from that, it was just tap water with campden added. I got my ph meter calibrated, but was too rushed to take many measurements.

I split my batch in half and had about 4 gallons and 5 gallons going into the carboys. Each half had 7 oz hops at flameout. The 4.5 gallons was mostly simcoe, centennial, comet, apollo and some el dorado, the other had a bunch of kinds. I split the 7 oz in half and mixed them up and threw in the first batch after boil, then the rest 20 minutes later for 45 minutes before turning on the wort chiller. The 4 gallons had a longer hopstand since I only had one chiller. I didn't check temperatures since i had too much to do on cleaning and getting ready to go out. All the hops and trub are in the carboys also.

I made a 3.8 liter gigayeast stepped starter for all three batches. I added some to the 2.5 gallon partigyle at 1.058, then split the rest between the others. I made a 2.25 l starter, decanted and added that to a 1.6 l starter, then decanted to about 400ml to pitch in my beer.

I used 20ml of hopshot for the 90 minute boil. I ordered the hopshot in October so I was not sure if it had any shelf life issues in my fridge for a month. I am wondering if I should have bumped it up, but its too late now.

There was some little black specs floating in the kettle, not sure if that was from the hop extract or sugar in the raw. They are floating on the krausen.

Used 24 lbs pearl, 1.5 lbs TF white wheat, 1.5 lbs caramalt, 1.5 lbs sugar in the raw. I got my grains and hopshot from farmhouse.

My OG was 1.093, but I think my hydrometer might be off and it could be higher.

My only concern at this point is if the bitterness is correct and how much volume the hops will suck up. Next time I won't try to mash as much grain in the cooler and will split it up for a beer this big. I am still in process on reading Water, and still have a lot to improve on that.

Pitched yeast yesterday and oxygenated around 60 degrees and they are now fermenting today. The chamber is set to 62 degrees.