megalomani

Well-Known Member

Wow seems the folks in this thread have mostly negative opinions about this design however the mood of the forum is often slow to change until clear evidence to the contrary. I on the other hand am very curious to test especially with the brew2live's positive report.

I already have a 25 ft 3/8" conventional IC but am very interested in getting something that is more efficient and will work for if I ever move up to larger batches. Don't have a recirculating system to whirlpool and don't really like stirring the wart manually because 1) I am lazy 2) would rather spend that time cleaning or getting my carboy ready and 3) I worry about introducing nasties (although don't think this has ever happened in the past).

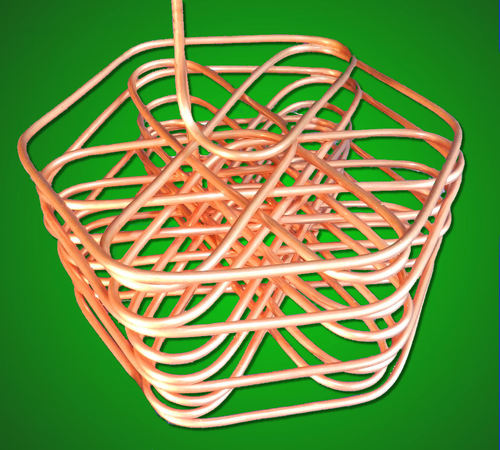

So my question is how difficult to replicate this design as a DIY. I have been studying the picture and think it may not be too difficult. From the overhead shot it looks like you could use 4 cylinders (such as spray paint cans) to help form the tube in this design for the inner pattern. For the outer portion of the pattern maybe carefully bending by hand or using more cylinders can help with the 90 bends.

Looking at pricing:

1/4" copper tubing 100ft $52-63 (coppertubingsales.com vs. orange big box respectively)

1/2" copper tubing 50ft $49-57

If you DIY the cost of copper for the "thing" chiller only is about 1/4 that of the standard design of 1/2" 50ft. The cost of water savings over time may also make this more fiscally appealing.

Anyone willing to try to DIY this and share how you did it? I might I have a go at it since I want to get myself a b-day present and I like tinkering.

If I do it I am going to double the length of copper. Brew2Live, would a 50ft length of this design be submerged in 5 gallon of wort? Can garden hose fittings be soldered on to this small of tube?

I already have a 25 ft 3/8" conventional IC but am very interested in getting something that is more efficient and will work for if I ever move up to larger batches. Don't have a recirculating system to whirlpool and don't really like stirring the wart manually because 1) I am lazy 2) would rather spend that time cleaning or getting my carboy ready and 3) I worry about introducing nasties (although don't think this has ever happened in the past).

So my question is how difficult to replicate this design as a DIY. I have been studying the picture and think it may not be too difficult. From the overhead shot it looks like you could use 4 cylinders (such as spray paint cans) to help form the tube in this design for the inner pattern. For the outer portion of the pattern maybe carefully bending by hand or using more cylinders can help with the 90 bends.

Looking at pricing:

1/4" copper tubing 100ft $52-63 (coppertubingsales.com vs. orange big box respectively)

1/2" copper tubing 50ft $49-57

If you DIY the cost of copper for the "thing" chiller only is about 1/4 that of the standard design of 1/2" 50ft. The cost of water savings over time may also make this more fiscally appealing.

Anyone willing to try to DIY this and share how you did it? I might I have a go at it since I want to get myself a b-day present and I like tinkering.

If I do it I am going to double the length of copper. Brew2Live, would a 50ft length of this design be submerged in 5 gallon of wort? Can garden hose fittings be soldered on to this small of tube?

instead of sitting at the kettle looking at the wort. Not sure how having more information on how chillers perform in varied conditions is a wasted test, but I'm really happy with this chiller and thought others would be interested in the results as well.

instead of sitting at the kettle looking at the wort. Not sure how having more information on how chillers perform in varied conditions is a wasted test, but I'm really happy with this chiller and thought others would be interested in the results as well.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)