Hey everyone, I'm Rob (obviously). New here as of last week and just beginning into the adventure that is home brewing. I'm starting out with extract, but eventually would like to venture into all grain.

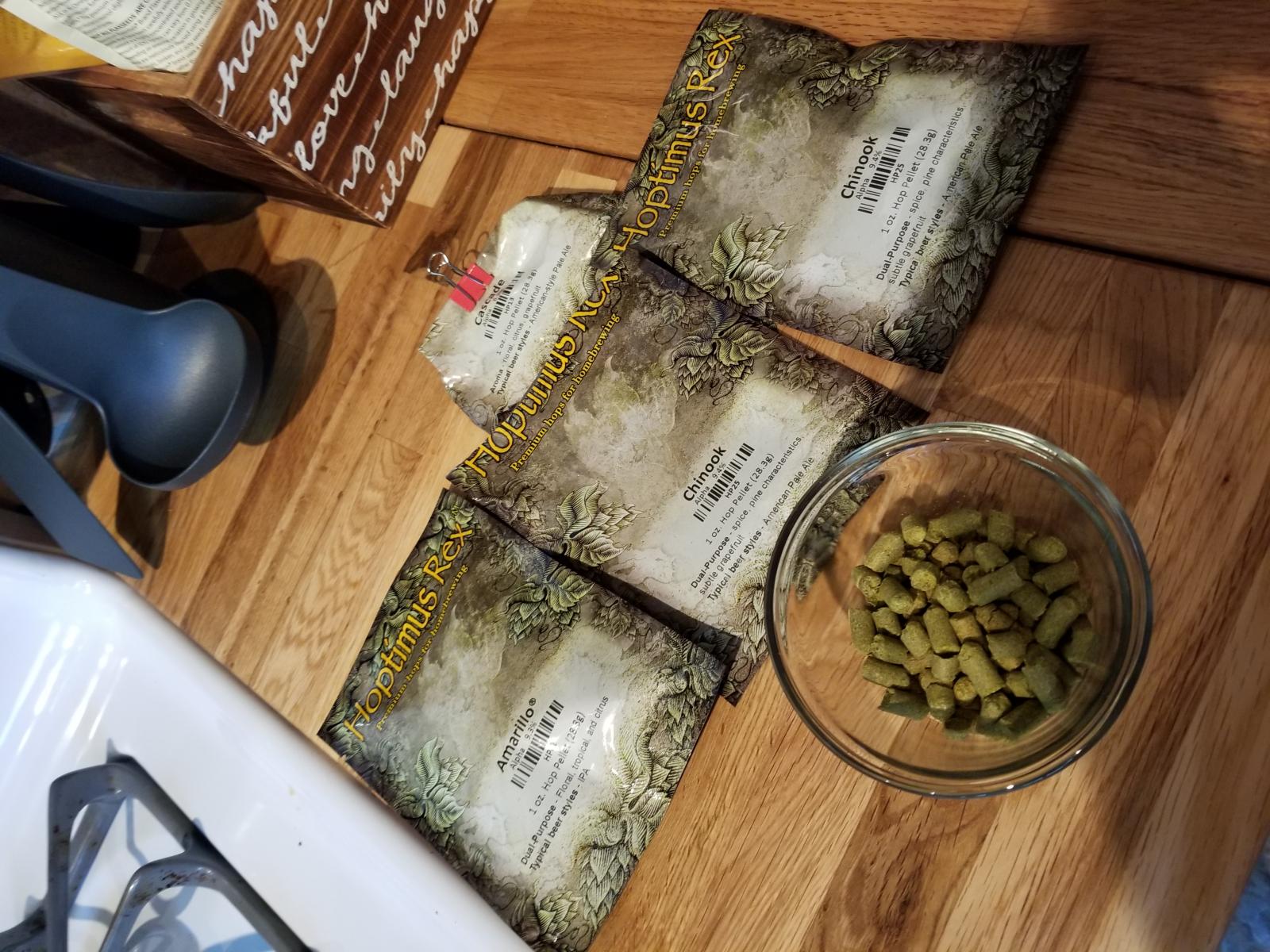

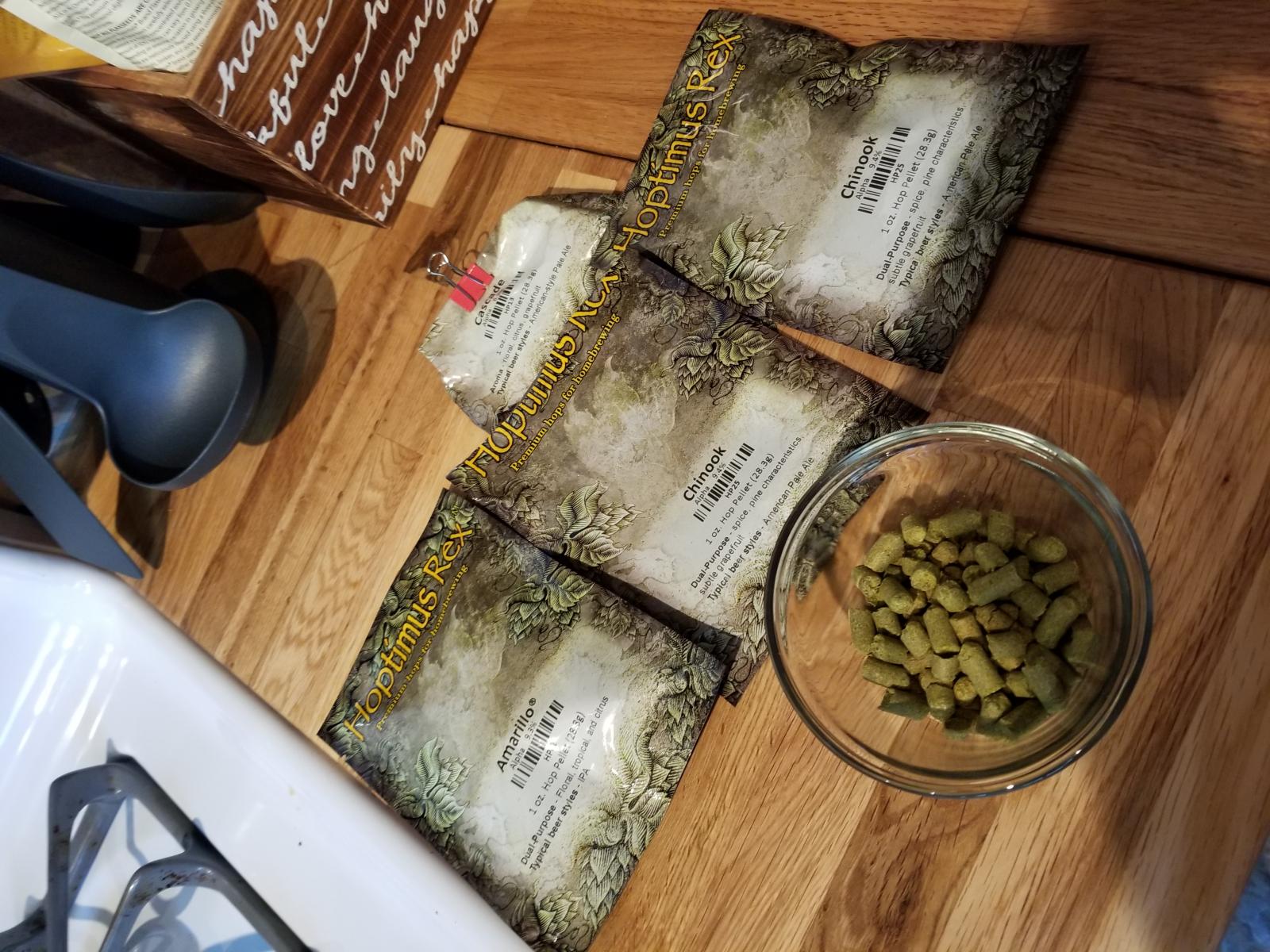

I just did my first batch this weekend of Norther Brewer's Grapefruit Pulpin IPA. Gotta say, pretty pumped for it. The first part seems to have gone well! Attached are some pictures I took during the process. The OG reading came out almost exactly where it should have - 1.065.

I do have some questions that came up during the process that I hope someone can shed some light on.

1. When steeping the grains at the beginning of the process, from what I've read, it says to steep for 20 min OR until the water hits 170 degrees, whatever comes first. I guess I have multiple questions to this. When I hit the 20 min mark, the water was at 150 so it still had 20 degrees to go. I pulled them out at the 20 min mark but what happens if you leave them in longer? Anything?

2. When you pitch your yeast into the fermenter, you never want to shake it or mix it, correct? Just let it do it's thing?

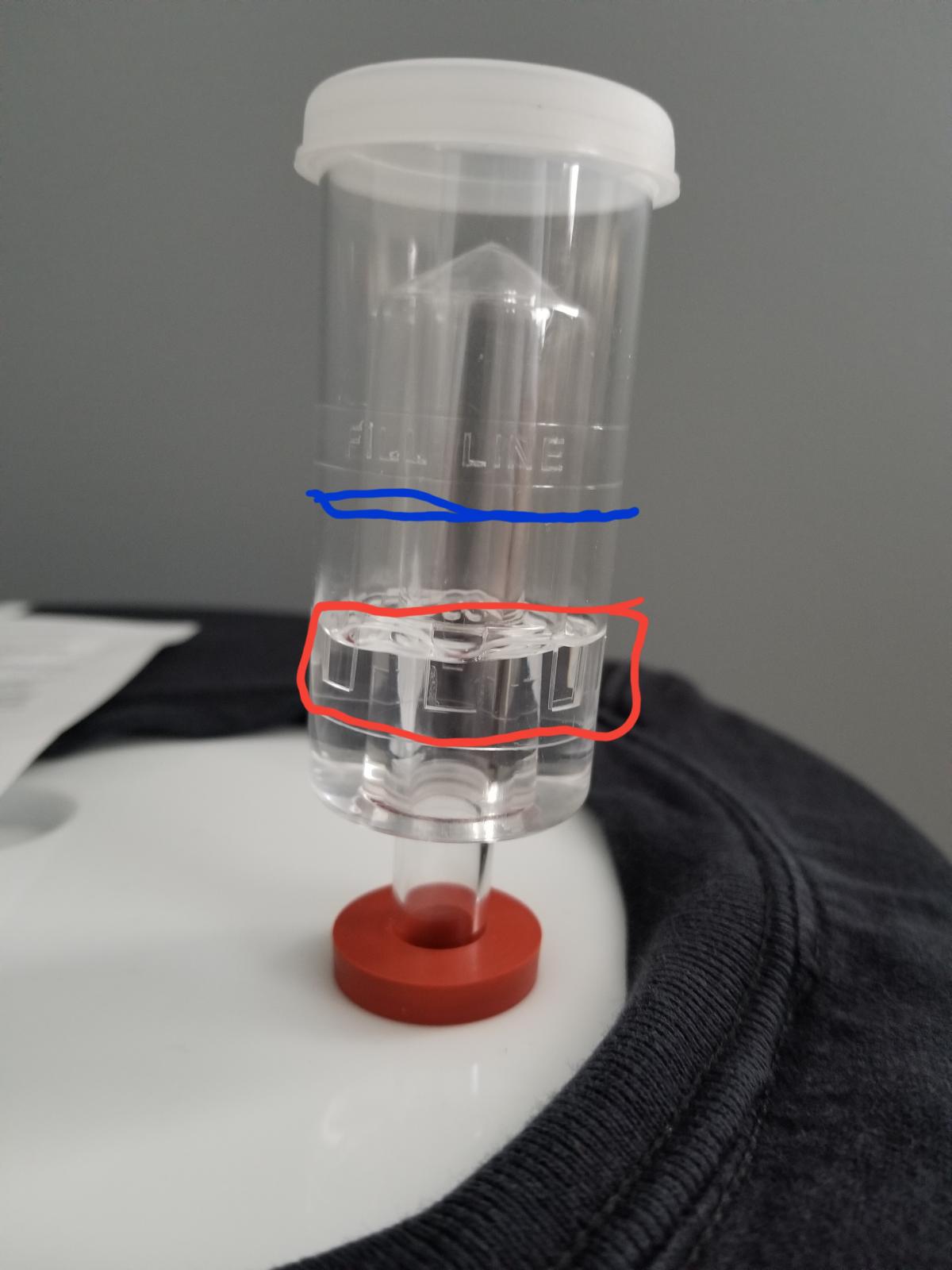

3. I bought the 3 piece airlock to use instead of the standard that comes with the kits. Is it possible to have the 3 piece filled TOO much? I did not see any markings on it as far as max fill lines or anything.

Thanks for the info in advance. Looking forward to learning from you guys.

I just did my first batch this weekend of Norther Brewer's Grapefruit Pulpin IPA. Gotta say, pretty pumped for it. The first part seems to have gone well! Attached are some pictures I took during the process. The OG reading came out almost exactly where it should have - 1.065.

I do have some questions that came up during the process that I hope someone can shed some light on.

1. When steeping the grains at the beginning of the process, from what I've read, it says to steep for 20 min OR until the water hits 170 degrees, whatever comes first. I guess I have multiple questions to this. When I hit the 20 min mark, the water was at 150 so it still had 20 degrees to go. I pulled them out at the 20 min mark but what happens if you leave them in longer? Anything?

2. When you pitch your yeast into the fermenter, you never want to shake it or mix it, correct? Just let it do it's thing?

3. I bought the 3 piece airlock to use instead of the standard that comes with the kits. Is it possible to have the 3 piece filled TOO much? I did not see any markings on it as far as max fill lines or anything.

Thanks for the info in advance. Looking forward to learning from you guys.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)