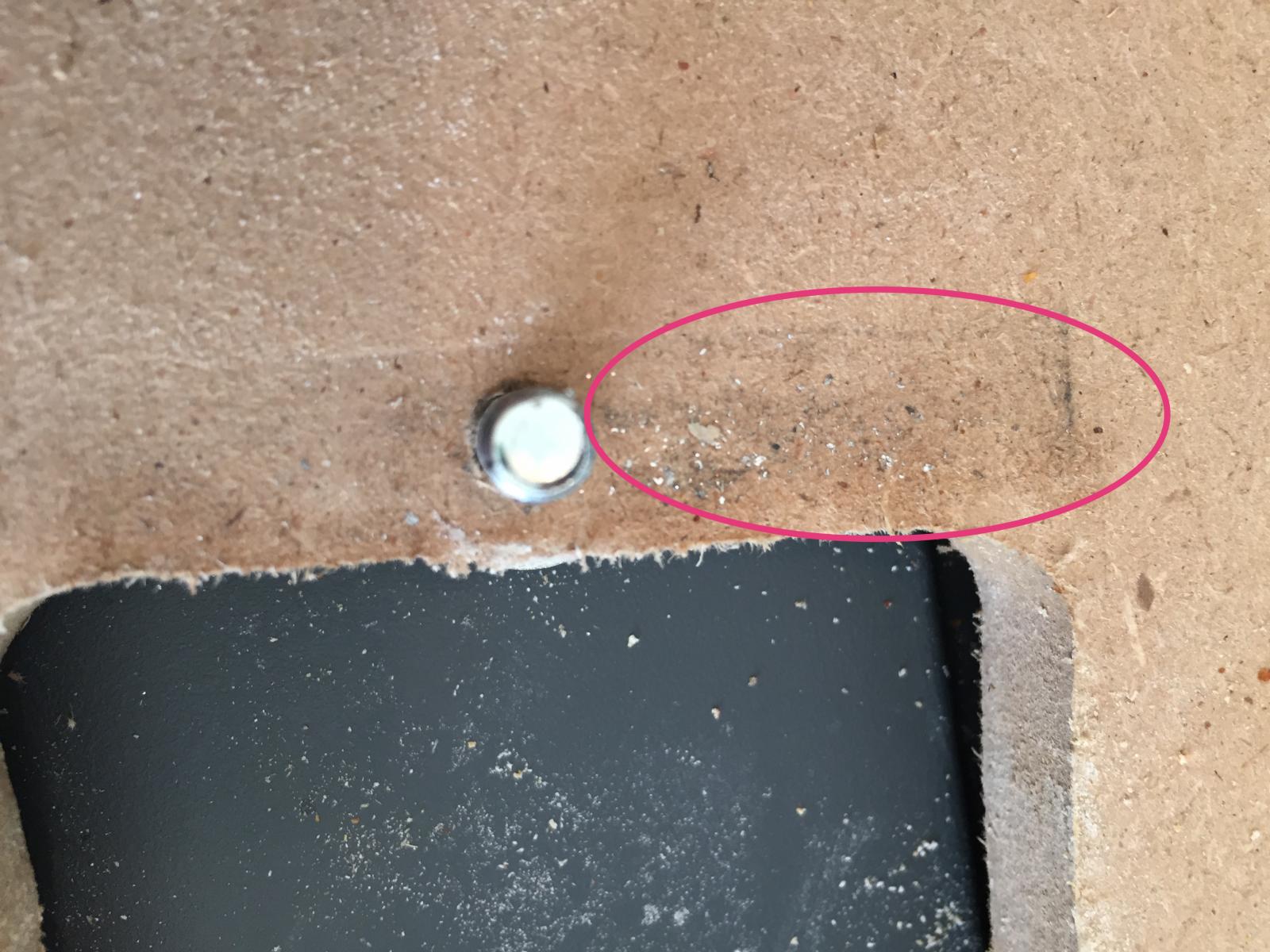

Noticed this morning (cleaning out my mash tun) that there was a small amount of metallic flecks at the bottom of the tun. After checking a few things and ruling them out, I ran a pound of grain through the Barley Crusher again.

Ran a rare earth magnet through it and knew the problem right away. For whatever reason small flecks of metal are coming off my mill. I've run about 80-100 pounds of grain through this mill.

My immediate question is if this is harmful? I don't think much made it to the boil and I've never seen this in the final product. I certainly don't want to dump this 5 gallon batch.

Secondly, is this a common occurrence?

Ran a rare earth magnet through it and knew the problem right away. For whatever reason small flecks of metal are coming off my mill. I've run about 80-100 pounds of grain through this mill.

My immediate question is if this is harmful? I don't think much made it to the boil and I've never seen this in the final product. I certainly don't want to dump this 5 gallon batch.

Secondly, is this a common occurrence?