Hello.

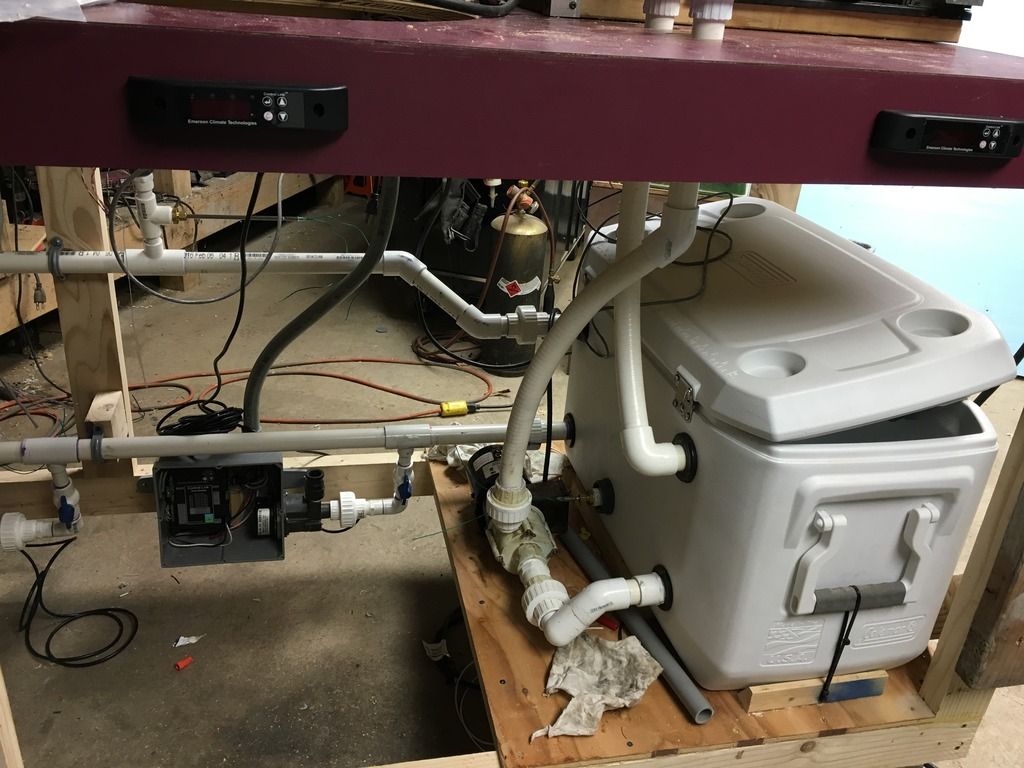

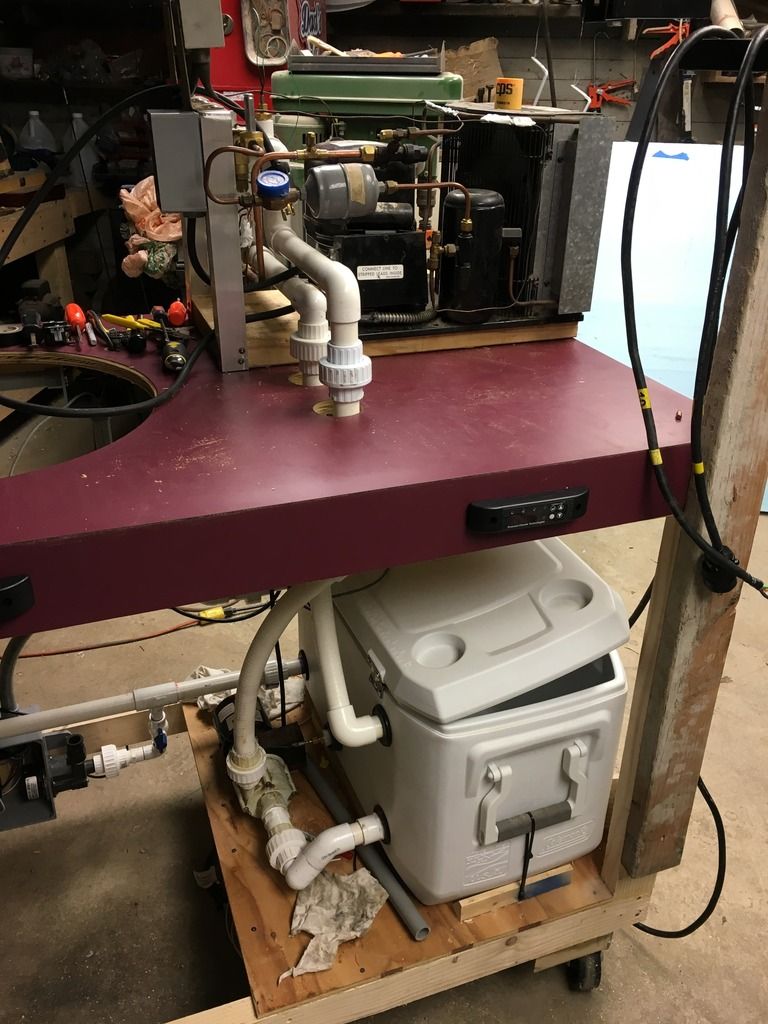

I have a DIY glycol system. The pump I used initially was a 1/4 HP superior pumps. The system sat unused for quite some time, and the pump no longer worked. I bought a replacement and it has been very noisy, and I suspect it is not going to last. I there a particular type of pump I need to be using? It is submerged in the glycol reservoir sump-pump type . The glycol is the kind used in MRI installations food grade and with additives to inhibit corrosion pre diluted. Would really be a pain to switch to a non submerged pump. The first pump I had seemed to work fine before it sat idle, this one is not even finished with its second fermentation and it sounds like it's dying.

TD.

I have a DIY glycol system. The pump I used initially was a 1/4 HP superior pumps. The system sat unused for quite some time, and the pump no longer worked. I bought a replacement and it has been very noisy, and I suspect it is not going to last. I there a particular type of pump I need to be using? It is submerged in the glycol reservoir sump-pump type . The glycol is the kind used in MRI installations food grade and with additives to inhibit corrosion pre diluted. Would really be a pain to switch to a non submerged pump. The first pump I had seemed to work fine before it sat idle, this one is not even finished with its second fermentation and it sounds like it's dying.

TD.