- Joined

- Dec 1, 2015

- Messages

- 159

- Reaction score

- 18

I’m currently looking into a new glycol chiller I’m looking at the statsis and ice maker 100 was wondering if anyone can help me with pros n cons on them

Cheers!

Cheers!

Ill give you the pros and cons of the icemaster max4, here we go:

Pros: Tank reservoir is 8 gallons

Not too loud when kicking on

comes with 4 pumps and controllers

Cons: controllers: they swing and overshoot every single time

Size: it is rather large

instructions: absolutely an abomination.

Overall im kind of happy with it, the grainfather helps with some things like overshooting the temps and turning the heater on in the cone. I really want to rip out the controllers and put all ITC-308 controllers in it, i think that would help overshooting so much and keep the temp in check better.

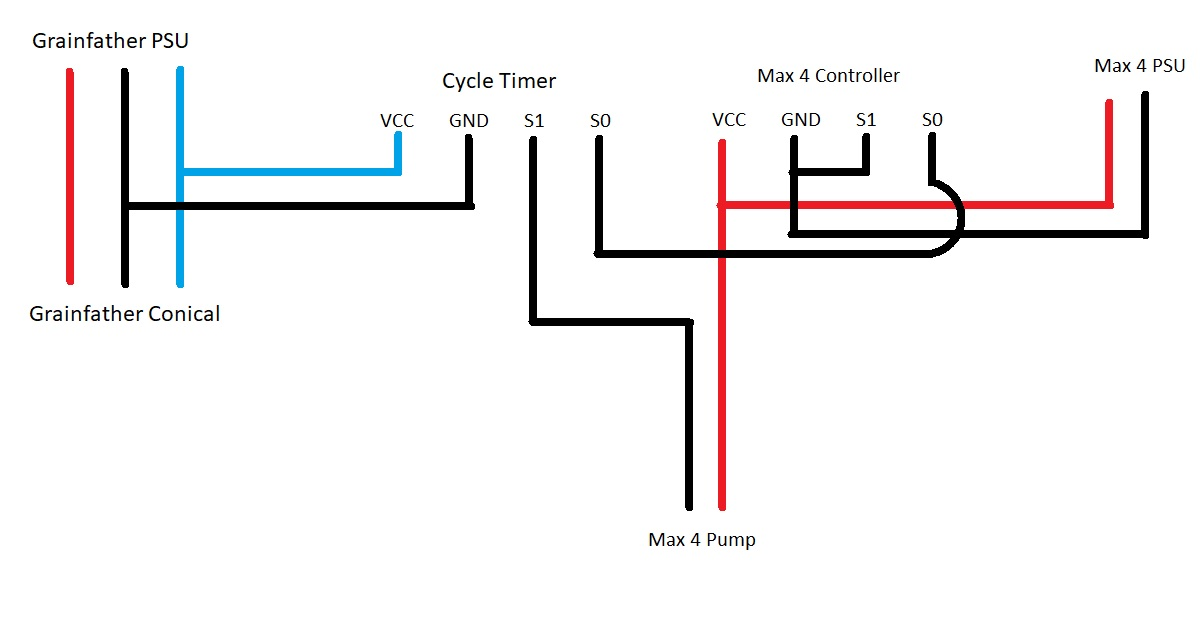

Hi there, I use the blowoff/thermowell from nor cal brewing. So I have the heaters set to where they come on at the lowest temp im ok with, then the pumps set to the desired temp, which always overshoot. Is there anyway you have that wiring schematic anywhere or you could send it? That is smart because i do think the pumps dont need to push all the time and could cycle off to avoid the overshooting im dealing with. Damn good idea man.How are you connecting the icemaster's pump controllers to your grainfather conical? I'm assuming you have the controller on the grainfather and not just the simple/basic lcd temp display that they ship with it. I had overshoot problems with my grainfather conicals when I first used them with a glycol chiller (icemaster 100). The problem occurs because the cooling sleeve is near the top of the fermenter and the temperature probe is near the bottom. There seems to be a delayed effect during a cooling cycle, in which the effects of cooling are not realized by the probe immediately. I fixed this issue by installing some programmable cycle timers that allow me to set a duty cycle for the pumps when cooling is called for. Check out my posts in this thread for more information:

https://www.homebrewtalk.com/threads/brewbuilt-icemaster-max-4.680883/

Advance, thank you so much for this diagram. Im gonna print this out tomorrow at work and study it so i can at least wire 2 controllers up. Weird thing is i put on a NEIPA this weekend into the second grainfather and the controller keeps temps perfectly! Its a 1/2 degree higher from the GF thermometer to the thermowell of the norcal blowoff tube. i still want the controllers wired the way you have them for pump longevity and effectiveness.That sounds like a pretty weird setup. It seems like the max4 is not really suited for the grainfather conicals because there is no thermowell to stick a probe. The wiring on the grainfather is fairly simple. The cable that plugs into the back of the fermenter has three wires: +12 VDC, GND, and a signal wire. The signal wire is +12 VDC when the controller calls for cooling. This wire is used to directly power the pump that is included with the basic cooling kit. The cycle timer inputs consist of: VCC, GND, S0, and S1. I think the simplest way to wire one of the cycle timers to use with your grainfather and max4 would be as such:

View attachment 694809

The blue wire in the above diagram is the signal wire comming off the grainfather. I think the actual color of this wire in the cable is white. This configuration would bypass the controller on the max4 and allow you to use the grainfathers controller for both heating and cooling operations. Simply set the max4 controller for a low temperature (30F) and keep its probe connected but not inserted into the thermowell (have it read room temp instead). This will make the max4 controller constantly call for cooling, however the pump will not run until the normally open relay in the cycle timer is closed by the grainfather controller. Once the cycle timer is powered by the grainfather, you will be able to control the duty cycle for the pump. If you wish to program the cycle timer without running the pump, simply setup the max4 thermostat for a idle cooling condition and the grainfather for a active cooling condition. This might be as simple as unplugging the probe on the max4 controller and reducing the temp and the grainfather controller.

Just curious on your results of the Penguin. I too am looking for a good chiller solution and seems like so many brands are out of stock right now. The one thing I noticed about the Penguin is that the 1/2 hp model only has a 2 gal reservoir, and their 1 hp model a 3 gal. That seems a good bit lower than many of the other chillers out on the market. Thanks in advance.I ordered a 1/2hp Penguin through Spikes website. Shows up today. Can't give my personal pro's/con's yet, but based on my research this fit the bill perfectly for me.

Just curious on your results of the Penguin. I too am looking for a good chiller solution and seems like so many brands are out of stock right now. The one thing I noticed about the Penguin is that the 1/2 hp model only has a 2 gal reservoir, and their 1 hp model a 3 gal. That seems a good bit lower than many of the other chillers out on the market. Thanks in advance.

Sorry to continually beat this dead horse, but...

The one question that keeps rolling around in my head is why is the reservoir only 2 gal on the Penguin and 10 gal on the Ssbrewtech 3/8HP? And what exactly does that mean for efficiency and ability to cold crash while holding temps on another fermenter? Is this all a moot point, that provided there's enough coolant any extra volume is superfluous, or does the extra volume actually lead to less cycles for the chiller?

I'm going to email Eric at Penguin, this could sway me one direction or another in this purchase. I'll report back if I get an answer.

I didn't select the 1/5HP because I didn't feel this was a good comparison to the 1/2HP penguin in both horsepower and BTUs, however that is certainly up for debate. I heard from Eric and he left me a very detailed and thoughtful reply that not only showed me how I wasn't comparing apples to apples (the SSBT 3/8 HP to the Penguin 1/2 HP) but also explained the difference in reservoir sizes. I'm going to seek his permission prior to posting his reply word for word, but suffice to say that the differences in reservoir are less than meets the eye in both actual numbers as well as impact on the chiller. Furthermore the it seems there is a significant difference in motor configuration. Eric reports that the motors on the Penguin are of a rotary configuration, whereas the SSBT motors are reciprocal. He believes their motors are more reliable in the long run; less moving parts.Curious why you didn't list the 1/5 hp Ss Brewtech model chiller. I can run a 7 gallon unitank, Chronical and BrewBucket simultaneously. The reservoir is ~ 4 gallons. I run a 3:1 ratio of water to glycol set to 26F, ambient area varies temperature between 66-72F year-round. As long as I'm not crashing one fermenter, there's no problem maintaining temperatures in the FVs in the low 50s to low 60s for each one, but extended lagering I do in a keg in a beer fridge. Had it for a year now, no burps or hiccups. The on/off cycling has not been an issue, nor have extended runtimes. Very pleased so far.

As long as you're not trying to crash two 14 gallon conicals or lager three 7 gallon vessels, you'll have more than enough cooling power and won't go broke buying glycol to fill a 10 gallon reservoir.

Brooo Brother

Just to answer your questions, I was thinking that chiller efficiency has less to do with what I want to cool verses how the chiller itself operates. Obviously if I am trying to cool a 3BBl fermenter it would be important for me to select a chiller that was up for that job, but in this case I'm just looking at 7 - 15 gal fermenters; maybe even a unitank someday soon.It would depend on how you define efficiency. I think the larger reservoir helps if you are cooling a large vessel like a 1 BBL brite tank. In my setup, I am cooling a 7 gal and a 14 gallon fermenter and I have never had an issue (I also have cooling on 2 - 4 gallon Anvils) but I never run more than 2 fermenters at a time. I doubt the tubing and coil hold more than a cup of coolant. With a large reservoir, it may not cycle as often but it will run longer to cool.

Penguins chillers have been around awhile and I am sure Spike would not recommend them if there were problems.

What size vessel are you trying to cool?

I didn't select the 1/5HP because I didn't feel this was a good comparison to the 1/2HP penguin in both horsepower and BTUs, however that is certainly up for debate. I heard from Eric and he left me a very detailed and thoughtful reply that not only showed me how I wasn't comparing apples to apples (the SSBT 3/8 HP to the Penguin 1/2 HP) but also explained the difference in reservoir sizes. I'm going to seek his permission prior to posting his reply word for word, but suffice to say that the differences in reservoir are less than meets the eye in both actual numbers as well as impact on the chiller. Furthermore the it seems there is a significant difference in motor configuration. Eric reports that the motors on the Penguin are of a rotary configuration, whereas the SSBT motors are reciprocal. He believes their motors are more reliable in the long run; less moving parts.

In the end I was left feeling like Penguin not only stands behind their products but also are available to discuss/debate the pros and cons of those products. I will say he won me over, I will be ordering a Penguin soon.

I own both a Stasis and the 1/3hp Penguin. Both work fine for controlling fermentation temps. I have a Spike Flex+ and a Spike CF5, both with neoprene jackets, BTW.

I own both a Stasis and the 1/3hp Penguin. Both work fine for controlling fermentation temps. I have a Spike Flex+ and a Spike CF5, both with neoprene jackets, BTW.

Do people just normally dump the extra amount?Push it out either with CO2 or compressed air? The real question is, why do you want to recover it at all?