I can toss out my experiences about how this efficiency thing works when doing bigger grists.

Efficiency with a bigger beer will drop, if you do it "the normal way", just scale the brew up, without scaling down efficiency.

So #1 is that you have to account for the efficiency drop.

#2: I read in the opening post that the second time you used less water do get a higher density. This will also make your efficiency take a nosedive, as efficiency is a function of both the SG and the wort you're available to extract. More malt will bind more liquid to the malt. And, it's easier to extract more sugars with more water in the mash. A thinner mash.

You can try this to remedy the issue:

If you look at a brew you've done, lets say a light beer which has 50/50 mash/sparge water. If you'd scale that up, you'd be more like 70/30-ish mash/sparge water due to the higher grav beer requires more grains, if you're going for the same mash thickness.

What you can do is use more sparge water, so the 70/30 will get back to 50/50, more sparge water used than calculated in other words. This will make you have to boil it back down in the kettle though, so you're looking at several hours of boil time. But, if you do this, you'll get pretty close to your targeted efficiency without have to scale the efficiency back.

Look at the proportions of the water use at a lower OG beer, and try to target that proportion in the higher grav beer. Take it from there for the next brew after that

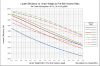

Correct. It turns out that the lauter efficiency for a fixed lauter process (no-sparge, single batch sparge, double batch sparge, etc.) with constant strike water to sparge water ratio, and consistent grain absorption rate, depends only on the grain weight to pre-boil volume ratio. For example if you do a no-sparge process, a grain bill of 10 lb with a 6.5 gal pre-boil volume will have the same lauter efficiency as a 15 lb grain bill with a 9.25 gal pre-boil volume, which will be the same as a 20 lb with 13 gal. If the grain bill goes up without increasing the pre-boil volume proportionately, the lauter efficiency goes down. Since mash efficiency = conversion efficiency * lauter efficiency, it will also go down, as will brewhouse efficiency which = mash efficiency * fermenter volume / post-boil volume.

Edit: Here's a chart that shows how lauter efficiency varies with the grain bill weight to pre-boil volume ratio for several different sparge processes and two different grain absorption rates (0.12 gal/lb is a typical MLT value, and 0.06 gal/lb represent aggressive squeezing.)

Brew on

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)