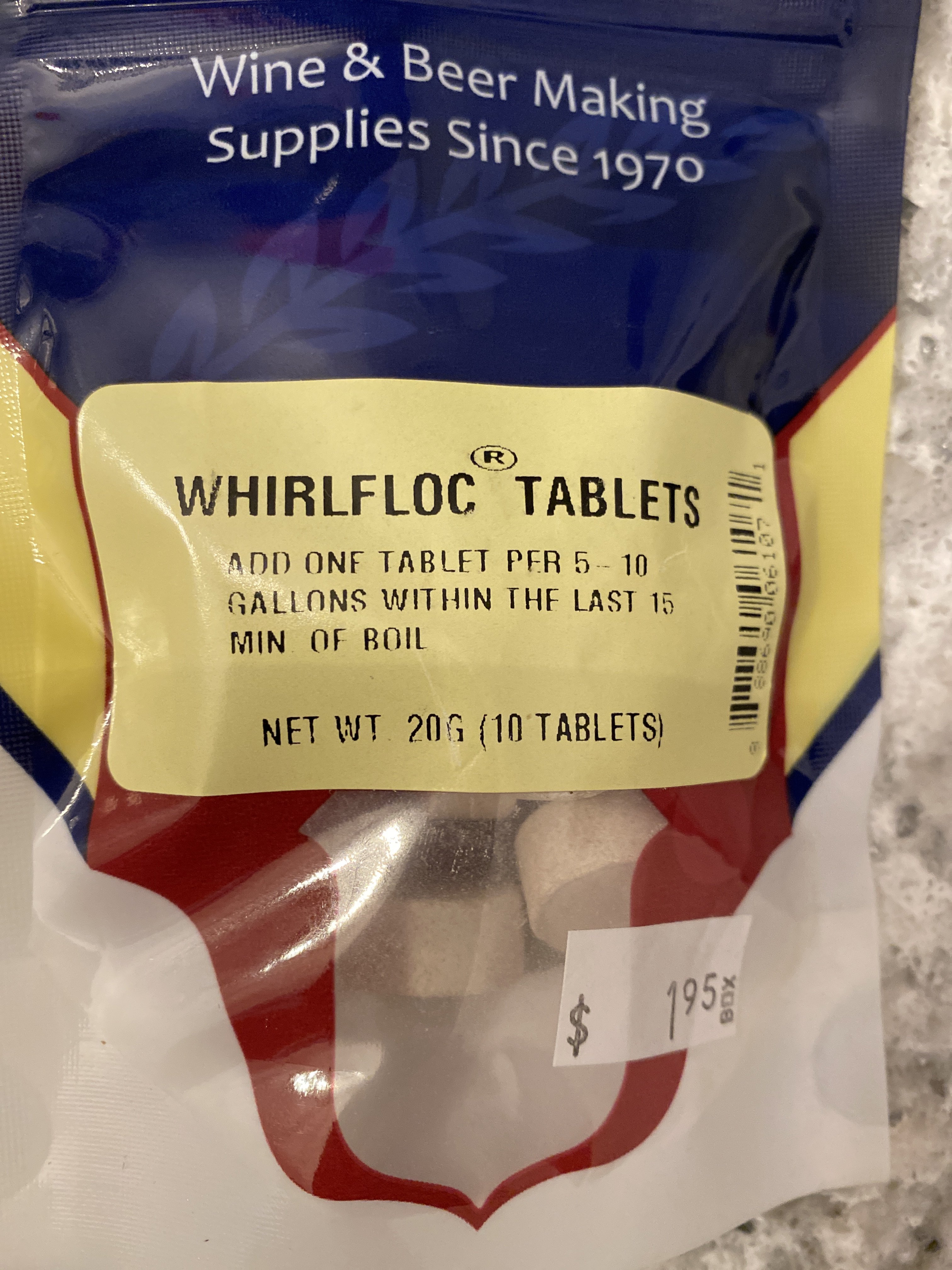

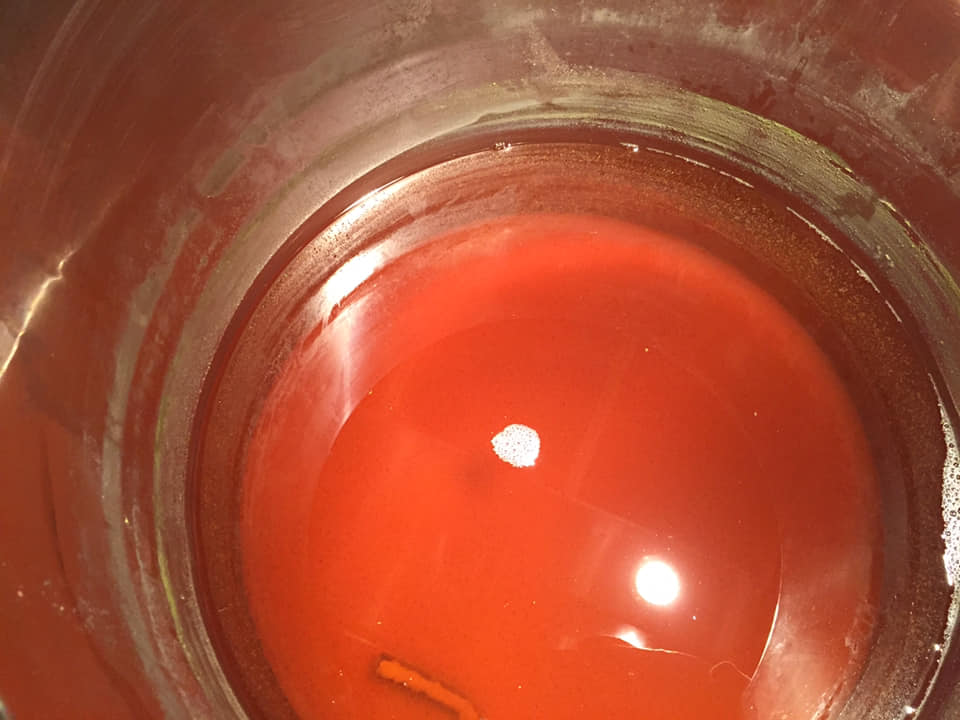

Every time I try to use Whirlfloc, I end up frustrated with it. I just finished brewing an Altbier. Added in Whirlfloc with about 5 mintues to go. Whirlpooled once it was chilled and let it sit for 30 minutes before I start transferring to the fermenter. Top layer looks spectacular and clear. Siphon it off and once I get down to just below the 2 gallon mark, it's still a ton of floating trub/hops. I didn't have a nice layer of sediment, it still had a considerable amount suspended. It was a 4 gallon total batch. Without Whirlfloc, I typically leave .5-7.5 gallons left in the kettle when I transfer. So it feels like I'm losing a lot of good wort when I use Whirlfloc because i don't feel like everything settles out like it should before I transfer. This is essentially the same every time I use it. I mean, I get I'll lose volume with what settles out due to the whirlfloc but I just wish it would settle down better and leave me more extractable wort. Any suggestions?

I left the floating mess and just pitched less yeast to compensate in to the super clear wort.

I left the floating mess and just pitched less yeast to compensate in to the super clear wort.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)