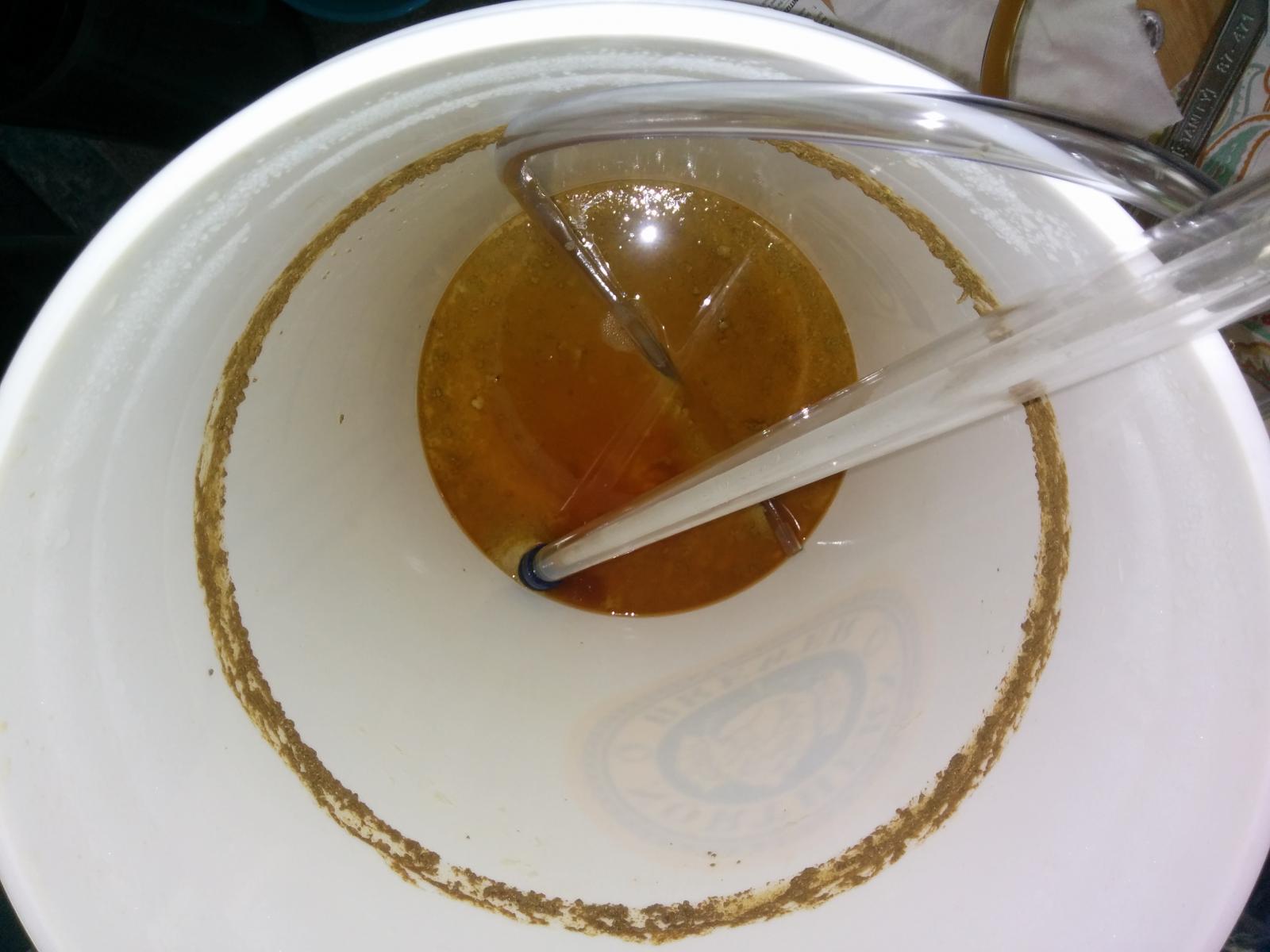

My first batch has been fermenting for two weeks, which is how long it should take according to the instructions that came with the kit.

My kit only included instructions on how to bottle the beer. Are there instructions somewhere on how to go from a primary bucket to keg, including how to sanitize everything? The keg is used and was washed/ refurbished from the seller.

The kit also came with a packet of sugar. Do I need to use this if kegging?

I've watched a couple of youtube videos but I still feel like I don't have the whole picture together. I don't want to mess this up.

Thanks.

For really light beers (blondes, very pale ales) some will compress fermentation time down to 10 days if in a rush. Dark heavier beers can need 4 weeks to finish. But a general rule of thumb for most beers, two weeks should be considered a minimum fermenting time with three weeks being typical. Give the yeast time to do their thing.

For a used keg, probably a good idea to disassemble and clean everything. Check the seals to make sure they are in good shape or were replaced already by the seller. Let everything dry completely before reassembling.

Jump in the car and head off to your local HD. Buy a 5 gal bucket with one of the snap rings that allow the top to be twisted on and off so you have a storage container for your sanitizer. Then mix up a 5 gal batch of starsan in your new bucket.

I assume you'll be using an auto siphon to rack your beer? They are easy to use but like most things, it takes doing it a few times to get the hang of it and do it well/cleanly. If it is your first time racking a beer, I would suggest racking into a bottling bucket (with spigot) to keep from sucking up a lot of solids into your keg. Once you become more comfortable with using the auto siphon, you can probably skip the bottling bucket step.

When racking ALWAYS try to avoid splashing and sucking air into the auto siphon. Make sure the racking tube is sitting on the bottom of the bucket and the flow into the bucket is as "calm" as possible. This is to prevent oxidizing your beer.

Move the fermentor to the location where you plan to rack into the keg a few hours prior in order to give any disturbed solids a chance to settle back down.

Once you're ready to keg your beer, fill the keg about about half full of startsan. Put the lid on and give it a very small shot of CO2. Then get a screw driver or something to depress the poppet valve on the "out" post so the starsan fills the dip tube and begins to come out of the post. Then place the keg on it's side. While you're getting everything else ready, just reach over a few times and give a roll to make sure the starsan contacts all surfaces within.

Next, sanitize your bottling bucket and don't forget the spigot (if you decide to use it), auto siphon and tubing. Then rack the beer into the bucket. Place the lid on the bottling bucket then elevate the bucket so it's higher then the top of the keg so gravity will help the beer will flow. Then give it a few minutes to settle.

Dump the startsan out of the keg. Make sure to depress the poppet valve on the out post to drain the starsan from the dip tube.

Connect the tubing to the spigot on the bottling bucket and place the other end in the keg so it's resting on the bottom of the keg. To start the flow of beer into the keg, I like to lift the keg up so it's at about the same level as the bucket. It helps to slow the initial flow and fills the tubing with beer faster instead of letting the beer run with air in the tubing. Once the tubing fills, you can place the keg back on the floor. As before, try to prevent splashing.

Once full, place the lid, seal the keg and leave it where it stands. Don't move the keg around so the beer splashes as there is still o2 in the head space.

To purge the keg of O2, connect the CO2 bottle to the "In" post with the regulator set on 15psi and open the valve. When the sound of CO2 flowing into the keg stops, close the valve and purge the keg by pulling the pressure release. Repeat this action about 5 or 6 times.

Now open the valve on the CO2 and turn the regulator up to 30psi and chill to serving temp. Leave at 30psi for about 30 hours. At the 30 hour mark, turn the valve off and bleed CO2 from the keg. Reduce the regulator to serving pressure (i like 11-12psi) and reopen the valve. It should take a few more days for the carbonation level to equalize.

Oh, and give the corn sugar that came in your kit to someone who needs it. You certainly don't.

That's my post for the day...

Let us know how everything goes.

Good luck and enjoy!