I added a reply to the long "Soldering Stainless Steel" thread a couple days ago describing how I had formed a tapered lip on a hole in a keg lid, and threaded it to accept a 3/8" nipple. Someone (MacBruver) asked me for pictures.

I thought I'd start a new thread, so this doesn't get lost in that 18 pages and growing thread.

Here is my original description of what I did:

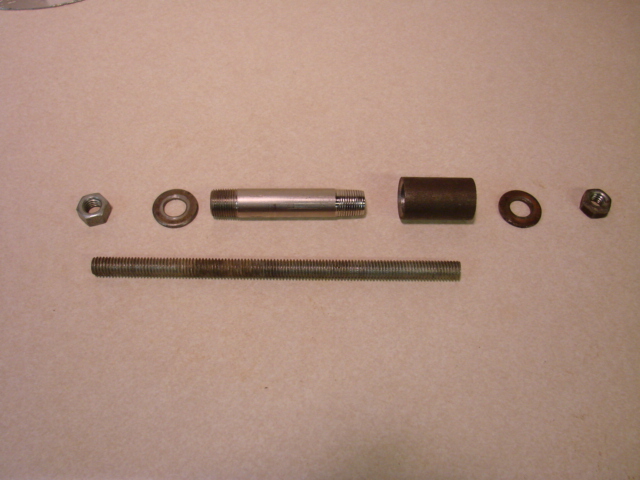

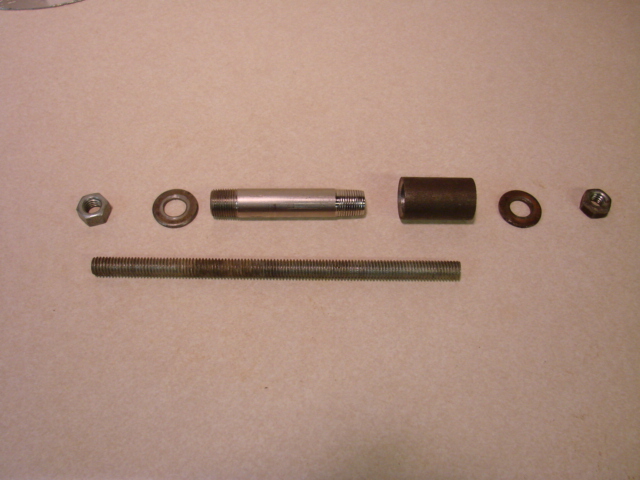

I was inspired by the posts in this thread about pulling a tapered fitting through a small hole to make a lipped hole for increased solder surface area to try something slightly different (see page 8 or so of the Soldering thread). Instead of having the sides of the lip parallel and at right angles to the wall of the keg, I wanted to make the lip tapered at the same angle as a tapered pipe thread. Then I wanted to thread it inside so I could screw in a nipple or reducing fitting, then solder it. My reasoning was the added mechanical strength from threading would improve the overall strength of the joint.

So I chucked a 3/8" nipple in my friend's lathe, and with his help we cut the threads off leaving the taper, then turned a little more taper on the first 1/8" of the "tool". I drilled a 1/2" hole in an old keg head left from keggle making and pulled the tapered tool through the hole about 3/4 of the way down its tapered section. I got a nice 1/16th inch lip that I was able to thread easily and just as easily screw the other end of the nipple into. It works great. I got about 2 full threads cut in the lip. Next will be to solder it to seal it up.

I did have to fiddle around to find the right size backup die to fit onto the back of the hole; too large a diameter and the lip didn't form, I just got a big dimple in the keg top. Too small a diameter and the tapered tool jammed before forming the lip.

I'm going to use this technique for all my small keggle holes for thermocouples and sight glasses. Either fitting nipples or 3/8" to 1/4" reducing fittings. I'll let you know how it works out, but right now I expect it will be great.

So, here are some pictures, of the tool and the threaded hole and with the nipple screwed in place. I was able to cut about 2 full threads in the lip. The hole I ended up happiest with is the one on the left in the picture, the rest are learning experiences.

I thought I'd start a new thread, so this doesn't get lost in that 18 pages and growing thread.

Here is my original description of what I did:

I was inspired by the posts in this thread about pulling a tapered fitting through a small hole to make a lipped hole for increased solder surface area to try something slightly different (see page 8 or so of the Soldering thread). Instead of having the sides of the lip parallel and at right angles to the wall of the keg, I wanted to make the lip tapered at the same angle as a tapered pipe thread. Then I wanted to thread it inside so I could screw in a nipple or reducing fitting, then solder it. My reasoning was the added mechanical strength from threading would improve the overall strength of the joint.

So I chucked a 3/8" nipple in my friend's lathe, and with his help we cut the threads off leaving the taper, then turned a little more taper on the first 1/8" of the "tool". I drilled a 1/2" hole in an old keg head left from keggle making and pulled the tapered tool through the hole about 3/4 of the way down its tapered section. I got a nice 1/16th inch lip that I was able to thread easily and just as easily screw the other end of the nipple into. It works great. I got about 2 full threads cut in the lip. Next will be to solder it to seal it up.

I did have to fiddle around to find the right size backup die to fit onto the back of the hole; too large a diameter and the lip didn't form, I just got a big dimple in the keg top. Too small a diameter and the tapered tool jammed before forming the lip.

I'm going to use this technique for all my small keggle holes for thermocouples and sight glasses. Either fitting nipples or 3/8" to 1/4" reducing fittings. I'll let you know how it works out, but right now I expect it will be great.

So, here are some pictures, of the tool and the threaded hole and with the nipple screwed in place. I was able to cut about 2 full threads in the lip. The hole I ended up happiest with is the one on the left in the picture, the rest are learning experiences.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)