- Joined

- Apr 11, 2006

- Messages

- 11

- Reaction score

- 1

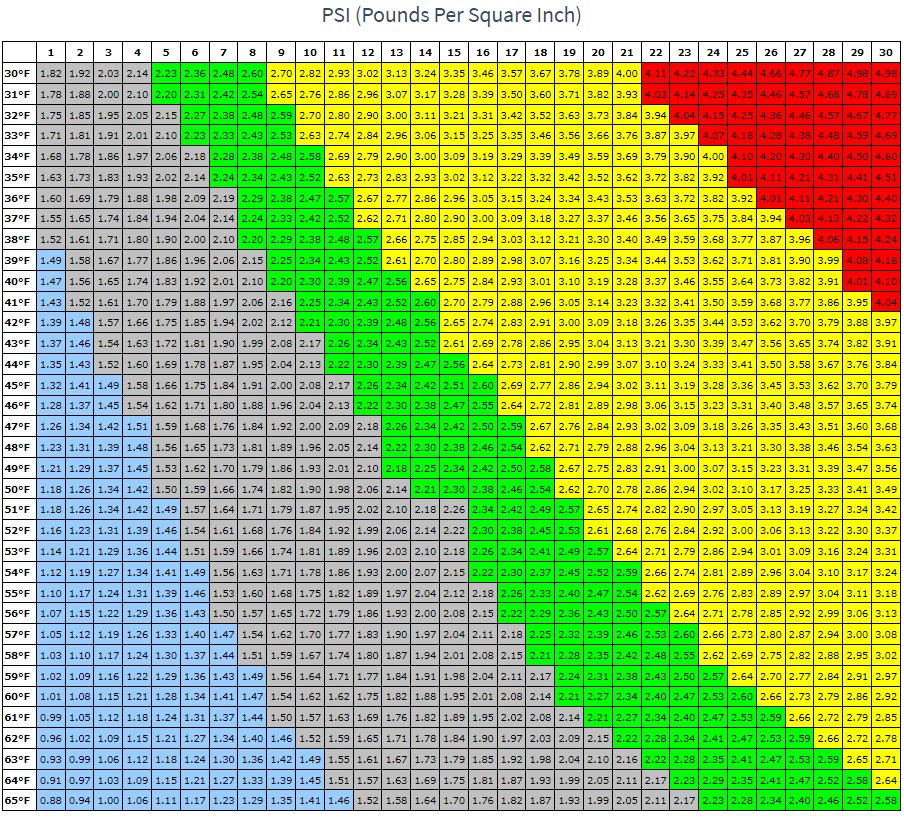

As the title says, I have a beer that has finished fermenting (under pressure) and I cold crashed it. Right now its sitting at 8psi after temp drop to 30f. I forgot to put in the dip tube so I am trying to figure out the best way to transfer to a keg while minimizing O2 as I usually do a closed transfer with a CO2 filled keg.

I have an active liquid pump I use for wine... was thinking of purging the keg, and un screwing one of the ball caps, sticking the pump line in there and wrapping it with plastic wrap, then adding 2-3psi of CO2 on the other ball valve and pulling all the beer into the keg. But, will it fill?

I could also, just unscrew the lid, attach the dip tube and drop it back in... but, I feel the top being open would add more O2 than the other method.

Any recos would be appreciated.

I have an active liquid pump I use for wine... was thinking of purging the keg, and un screwing one of the ball caps, sticking the pump line in there and wrapping it with plastic wrap, then adding 2-3psi of CO2 on the other ball valve and pulling all the beer into the keg. But, will it fill?

I could also, just unscrew the lid, attach the dip tube and drop it back in... but, I feel the top being open would add more O2 than the other method.

Any recos would be appreciated.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)