I am new to all grain. So far, when my batch sparing slows down to a trickle I have been reaching in with a spoon and mixing up the bed to get it to flow more. I believe this is a mistake causing me to have cloudy beer and lower than desired efficiency.

My mash/lauter tun can be sealed. So If I close the lid - it wont drain out the bottom any more.

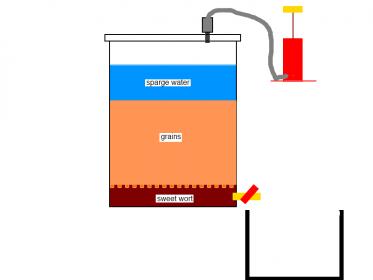

I am planning on taking the valve from a blown bike tire tube and attaching it to the lid of my mash/lauter tun. I would then hook my bike pump up to this valve and pressurize the air above the sparge water in the lauter tun. This would increase the hydraulic gradient through the grain bed and thus result in a larger amount of volume per time being expelled from the grains.

Any experienced all grainers see a problem with this plan?

My mash/lauter tun can be sealed. So If I close the lid - it wont drain out the bottom any more.

I am planning on taking the valve from a blown bike tire tube and attaching it to the lid of my mash/lauter tun. I would then hook my bike pump up to this valve and pressurize the air above the sparge water in the lauter tun. This would increase the hydraulic gradient through the grain bed and thus result in a larger amount of volume per time being expelled from the grains.

Any experienced all grainers see a problem with this plan?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)