Ok, I've read a ton of these foaming keg threads and I think I've tried everything with no solution.

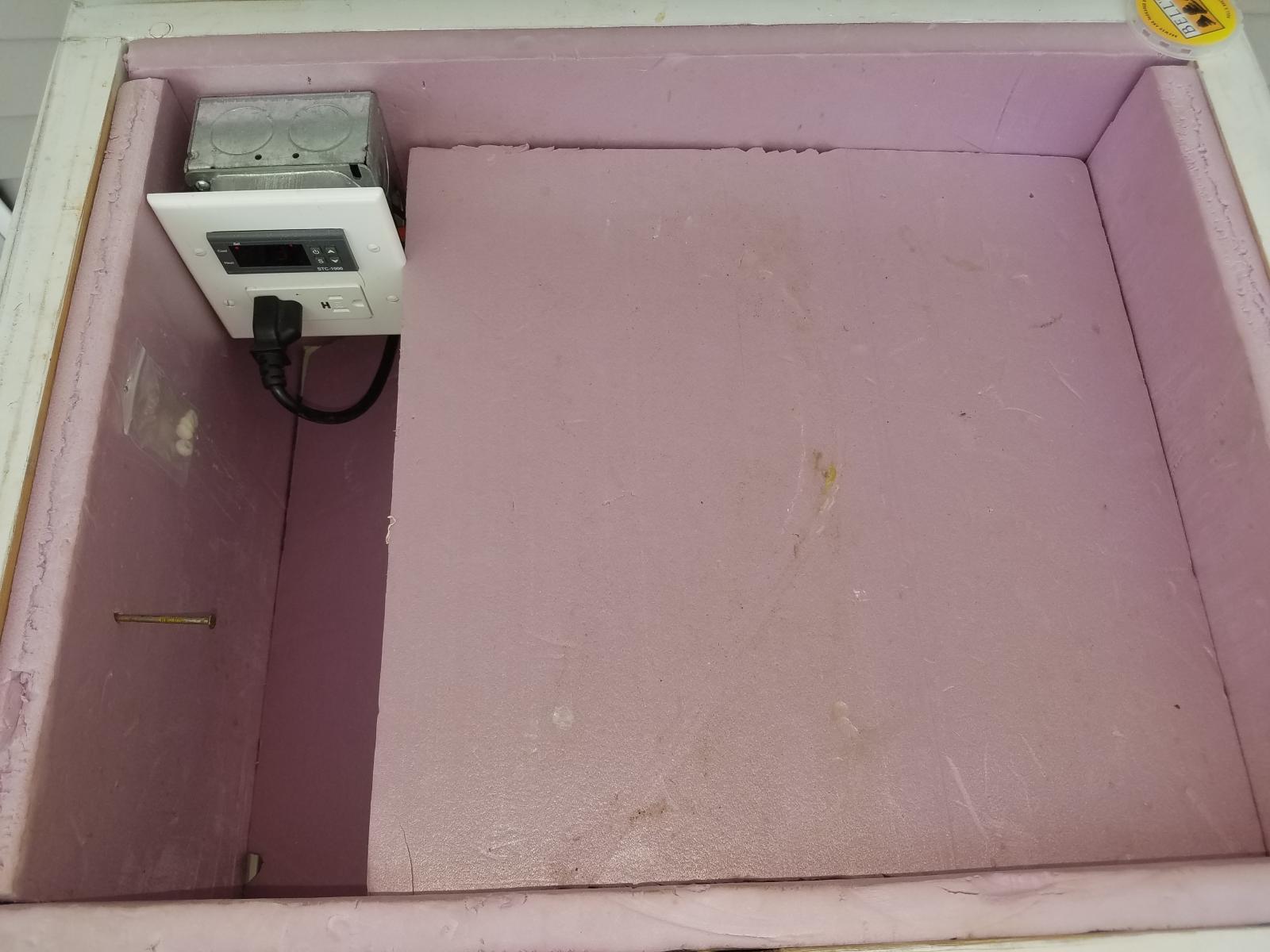

I have a keezer and the first pour has a lot of foam and I can't get rid of it. I have a fan in there running 24/7. Temp is around 37 degrees as measured by a grill thermometer which seems fairly accurate. 10' of 3/16 line from lhbs. Psi is currently set at 8 which provides for a pretty slow poor. I've tried as high as 12 PSI but the foaming seems worse. At this point, I am thinking that for some reason the beer in the lines are getting warm somehow because after the initial glass which is 3/4 foam it pours beautifully. If i sit's for an hour or so, it's back to foam. I know the easy answer is to not let my keg sit for a full hour without giving it proper attention, but unfortunately the wife gets upset when I use that practice. It kills me to dump this much brew out, does anybody have any ideas on what I'm doing wrong, or how I can fix it?

Thanks!

Mike

I have a keezer and the first pour has a lot of foam and I can't get rid of it. I have a fan in there running 24/7. Temp is around 37 degrees as measured by a grill thermometer which seems fairly accurate. 10' of 3/16 line from lhbs. Psi is currently set at 8 which provides for a pretty slow poor. I've tried as high as 12 PSI but the foaming seems worse. At this point, I am thinking that for some reason the beer in the lines are getting warm somehow because after the initial glass which is 3/4 foam it pours beautifully. If i sit's for an hour or so, it's back to foam. I know the easy answer is to not let my keg sit for a full hour without giving it proper attention, but unfortunately the wife gets upset when I use that practice. It kills me to dump this much brew out, does anybody have any ideas on what I'm doing wrong, or how I can fix it?

Thanks!

Mike