You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Floating (SS) keg pickups ?

- Thread starter brewman !

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Yep all my kegs have clearbeer systems. They are expensive but I'll never go back. Can keg hop with loose pellets and beer drops clear super quick.

Do you have a picture of one of the units ?

- Joined

- Dec 5, 2007

- Messages

- 1,719

- Reaction score

- 759

I bought one (the one Iseneye linked) as a Christmas gift to myself and I liked it so much I bought another about a month ago. I got the bare-bones model which cost about $47 each including shipping.

I'll probably stick with just two for the time being due to the cost even though my keezer has 4 taps. They really do work well though and if cash were no object I'd buy two more immediately.

I'll probably stick with just two for the time being due to the cost even though my keezer has 4 taps. They really do work well though and if cash were no object I'd buy two more immediately.

LLBeanJ

Well-Known Member

These Top Draw pickup tubes from Williams Brewing seem to work pretty well and are more economical.

https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

I put one on all 8x of my taps.

https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

I put one on all 8x of my taps.

These Top Draw pickup tubes from Williams Brewing seem to work pretty well and are more economical.

https://www.williamsbrewing.com/Top-Draw-Beer-Pick-Up-Tube-P4643.aspx

I put one on all 8x of my taps.

Thanks for sharing. Any idea what diameter they are ?

LLBeanJ

Well-Known Member

Thanks for sharing. Any idea what diameter they are ?

Not off hand, but I can measure when I get home this evening. I assume you're talking about the OD of the post insert that replaces the original dip tube, correct? I can say that they work just fine in both Cornelius and Firestone kegs.

LLBeanJ

Well-Known Member

I was actually referring to the ball diameter. Would love to know this.

Oh, gotcha. As a guess, I'd say it's around Ø1.75". I'll measure it this evening and update this post.

Update: The ball diameter is indeed 1.75".

Last edited:

McKnuckle

Well-Known Member

I have both the CBDS and the cheaper William’s top draw gadget. They both perform well, but the CBDS is heavier and hence more reliable at rising and falling as it should with the beer level.

The William’s product is lightweight, so the tubing length and flexibility can impact its buoyancy a bit sometimes. I haven’t had it happen in a serving keg yet, but in test runs with water it’s gotten hung up at the beer surface, if only temporarily. Not really a big deal at only $20.

I prefer the CBDS overall. A really nice product that should be talked about more!

The William’s product is lightweight, so the tubing length and flexibility can impact its buoyancy a bit sometimes. I haven’t had it happen in a serving keg yet, but in test runs with water it’s gotten hung up at the beer surface, if only temporarily. Not really a big deal at only $20.

I prefer the CBDS overall. A really nice product that should be talked about more!

McKnuckle

Well-Known Member

We hardly know each other, and you're asking me to weigh my balls? Geez, the noive...

I'm sure it would be easy enough to modify as you suggest.

I am using both successfully though. They both perform well in a 5 gallon keg, which is what the stock tubing length is designed for. I also have them deployed in some smaller kegs as well (2.5 and 3 gallon), where the CBDS is able to deal with that unmodified, but the William's top draw needed to have shorter tubing installed. Luckily I had some more of that same tubing in my gadget drawer, so I didn't have to alter the original length.

Bottom line, the concept is quite sound and I dig them. I actually fermented the beers in the same kegs that I'm serving from - another great benefit of the system.

I'm sure it would be easy enough to modify as you suggest.

I am using both successfully though. They both perform well in a 5 gallon keg, which is what the stock tubing length is designed for. I also have them deployed in some smaller kegs as well (2.5 and 3 gallon), where the CBDS is able to deal with that unmodified, but the William's top draw needed to have shorter tubing installed. Luckily I had some more of that same tubing in my gadget drawer, so I didn't have to alter the original length.

Bottom line, the concept is quite sound and I dig them. I actually fermented the beers in the same kegs that I'm serving from - another great benefit of the system.

I actually fermented the beers in the same kegs that I'm serving from - another great benefit of the system.

Please tell us more about this. Are you using Sanke or Corny kegs ?

McKnuckle

Well-Known Member

I have done the ferment-and-serve thing in 3 Corny kegs so far: First, I brewed a 3 gallon batch and split it into two 2.5 gallon kegs. So that's 1.5 gallons fermenting (and serving) in each. In one keg I pitched Czech lager yeast and brewed a nice pilsner, and the other one got a Belgian ale yeast.

I put the Clear Beer system in the pilsner keg and the William's top draw in the other one, just to compare them.

Then I brewed a 3 gallon batch and put that into a 5 gallon keg. That one is an English best bitter with WLP002. It's got another Clear Beer unit (I bought 2).

These are my first and only batches so far with this technique. But they are all extremely clear, and they cleared quicker than beer served via a bottom feeding dip tube. The pils in particular turned out amazing. It's been packaged for a month now, and there is no sign of any yeast or trub off flavors.

Fermenting in kegs is dirt simple; I just connect a QD to the gas port, and run a length of tubing to a blow-off jar. Then near the end of fermentation, I remove the blow off and allow some remaining CO2 to build up inside the keg. This is where spunding with a gauge would be useful, but for now I've been winging it.

With this technique, the beer literally never sees air or the light of day once yeast has been pitched. It's really nice and I plan to keep doing it, at least until I find a reason not to!

I put the Clear Beer system in the pilsner keg and the William's top draw in the other one, just to compare them.

Then I brewed a 3 gallon batch and put that into a 5 gallon keg. That one is an English best bitter with WLP002. It's got another Clear Beer unit (I bought 2).

These are my first and only batches so far with this technique. But they are all extremely clear, and they cleared quicker than beer served via a bottom feeding dip tube. The pils in particular turned out amazing. It's been packaged for a month now, and there is no sign of any yeast or trub off flavors.

Fermenting in kegs is dirt simple; I just connect a QD to the gas port, and run a length of tubing to a blow-off jar. Then near the end of fermentation, I remove the blow off and allow some remaining CO2 to build up inside the keg. This is where spunding with a gauge would be useful, but for now I've been winging it.

With this technique, the beer literally never sees air or the light of day once yeast has been pitched. It's really nice and I plan to keep doing it, at least until I find a reason not to!

McKnuckle: thank you for sharing that.

I've been thinking of doing this with 1/4 barrel (7.75 gallon) Sanke kegs for a long time. I installed a 4" TC port in one of my Sanke kegs so that I can get into the keg to clean it out and also possibly drop in a chilling coil to control fermentation temps, if I ever go glycol instead of a fridge I now use. Being that I have that port, I could drop in a float ball.

The nice thing about using 1/4 barrel Sankes is that I could up my batch size from 5 gallons to 7 gallons and still have headroom for krausen. Or if I went to 7.5 gallons, I could use a blow off tube like I do now with carboys. 5 gallon batches are a bit small if the beer is good. 10 gallons is kinda too much, for my equipment and to consume in a reasonable time, unless I'm throwing a summer party or it is my house beer. Even then it doesn't warrant me buying larger equipment. However my current equipment would easily make 7 or 8 gallons of wort into the fermentor(s).

I guess I could ferment 4.75 gallons in Corny kegs... it is just that the batch size is getting a bit small. I guess I could ferment 2 x 4 gallons per batch. My boil kettle is 11 gallons.

One of the big turn offs for me with conical fermentors is that very few are really airtight at pressure and almost none are built to handle the pressure necessary to carbonate beer for serving.

I don't get what all the fuss is about with them if you can't use them for serving. Most people don't do a secondary fermentation and autolysis isn't an issue if the beer is kept cold, so why do you need a conical ? So you can yeast harvest ?

The issue with yeast harvesting is that if you remove a quart of yeast out the bottom, you let a quart of air in at the top, unless you have some headspace at the top and you have it filled with pressurized CO2. But you don't want to be draining yeast out of a pressurized vessel either. So I don't understand the benefit of a conical.

Yeast autolysis is not an issue at serving temps. It might be at higher temps, I'd have to do some research on that.

I love the work and CO2 that your practice saves. I also love that the finished beer doesn't get exposed to any oxygen what so ever. I t can't get any fresher than that.

Have you done any dry hopping with your set up / practice ?

FWIW, I've been straining the hops, hot break and even some of the cold break out of my wort by recirculating it into a BIAB bag in the boil kettle at the end of the boil. It removes a lot of debris from the wort, makes for super clean wort. I hardly have any debris in my carboys at the end of fermentation, maybe 1/2" of yeast. Details here and here.

FYI, Brulosophy has tested the effect of fermentation headspace on beer quality, here. However, what I think they also inadvertently tested was the effect of only partially filling an unpurged serving keg as well.

It turns out that fermentation produces a TON of CO2. 5 gallons of 1.050 wort will produce between 11 and 15 cubic feet of CO2, depending on attenuation. Fermenting in a half full vessel (2-3 gallons of headspace) shouldn't cause any oxidation issues at all. Source

BTW, your process is called Unitanking.

I've been thinking of doing this with 1/4 barrel (7.75 gallon) Sanke kegs for a long time. I installed a 4" TC port in one of my Sanke kegs so that I can get into the keg to clean it out and also possibly drop in a chilling coil to control fermentation temps, if I ever go glycol instead of a fridge I now use. Being that I have that port, I could drop in a float ball.

The nice thing about using 1/4 barrel Sankes is that I could up my batch size from 5 gallons to 7 gallons and still have headroom for krausen. Or if I went to 7.5 gallons, I could use a blow off tube like I do now with carboys. 5 gallon batches are a bit small if the beer is good. 10 gallons is kinda too much, for my equipment and to consume in a reasonable time, unless I'm throwing a summer party or it is my house beer. Even then it doesn't warrant me buying larger equipment. However my current equipment would easily make 7 or 8 gallons of wort into the fermentor(s).

I guess I could ferment 4.75 gallons in Corny kegs... it is just that the batch size is getting a bit small. I guess I could ferment 2 x 4 gallons per batch. My boil kettle is 11 gallons.

One of the big turn offs for me with conical fermentors is that very few are really airtight at pressure and almost none are built to handle the pressure necessary to carbonate beer for serving.

I don't get what all the fuss is about with them if you can't use them for serving. Most people don't do a secondary fermentation and autolysis isn't an issue if the beer is kept cold, so why do you need a conical ? So you can yeast harvest ?

The issue with yeast harvesting is that if you remove a quart of yeast out the bottom, you let a quart of air in at the top, unless you have some headspace at the top and you have it filled with pressurized CO2. But you don't want to be draining yeast out of a pressurized vessel either. So I don't understand the benefit of a conical.

Yeast autolysis is not an issue at serving temps. It might be at higher temps, I'd have to do some research on that.

I love the work and CO2 that your practice saves. I also love that the finished beer doesn't get exposed to any oxygen what so ever. I t can't get any fresher than that.

Have you done any dry hopping with your set up / practice ?

FWIW, I've been straining the hops, hot break and even some of the cold break out of my wort by recirculating it into a BIAB bag in the boil kettle at the end of the boil. It removes a lot of debris from the wort, makes for super clean wort. I hardly have any debris in my carboys at the end of fermentation, maybe 1/2" of yeast. Details here and here.

FYI, Brulosophy has tested the effect of fermentation headspace on beer quality, here. However, what I think they also inadvertently tested was the effect of only partially filling an unpurged serving keg as well.

It turns out that fermentation produces a TON of CO2. 5 gallons of 1.050 wort will produce between 11 and 15 cubic feet of CO2, depending on attenuation. Fermenting in a half full vessel (2-3 gallons of headspace) shouldn't cause any oxidation issues at all. Source

BTW, your process is called Unitanking.

Last edited:

McKnuckle

Well-Known Member

Brewman - you and I are different in our batch size preferences, but other than that, the concept is exactly the same. Go for it!

I have not dry hopped yet, but I plan to soon. My next batch is another lager, a rauchbier, and following that I have a hoppy golden ale planned. I'll be dry hopping that one. I bought a couple of stainless keg hopping cylinders. Plus one of my CBDS units has their optional hop screen. I'll probably try the cylinder first.

Now let me check out the links you shared (thanks)...

I have not dry hopped yet, but I plan to soon. My next batch is another lager, a rauchbier, and following that I have a hoppy golden ale planned. I'll be dry hopping that one. I bought a couple of stainless keg hopping cylinders. Plus one of my CBDS units has their optional hop screen. I'll probably try the cylinder first.

Now let me check out the links you shared (thanks)...

If folks are dry-hopping this way, I'd love to learn their techniques.

Yep all my kegs have clearbeer systems. They are expensive but I'll never go back. Can keg hop with loose pellets and beer drops clear super quick.

++++on this! I’ve been using the CBDS in my kegs for several years with great success. The manufacturer also offers an easy to install SS mesh filter for the pick up that keeps out any floating hop debris.

Clear Beer is exactly what you get.

- Joined

- Nov 26, 2013

- Messages

- 7,661

- Reaction score

- 14,562

@McKnuckle , if floaty-top-draw is in keg for fermentation, doesn't it get all gunked up by krausen?

McKnuckle

Well-Known Member

Hey @balrog, I can only speak for the 3 examples I have going so far. The answer is no. Now, one is a lager, so it did not form a big top krausen. The other two are ales (T-58 and WLP002), which do generally form copious krausen. I haven't opened these kegs to see what the float looks like, I'm just judging by the beer, which is pristine looking.

The actual draw opening diameter on both products (CBDS and William's) is small, just like a regular Corny dip tube. So if there is krausen around the surface of the hose or the float device, it seems not to get sucked into the hose, so it doesn't ultimately matter.

Most likely the krausen just dropped in the cold, like you'd expect it to.

The actual draw opening diameter on both products (CBDS and William's) is small, just like a regular Corny dip tube. So if there is krausen around the surface of the hose or the float device, it seems not to get sucked into the hose, so it doesn't ultimately matter.

Most likely the krausen just dropped in the cold, like you'd expect it to.

- Joined

- Nov 26, 2013

- Messages

- 7,661

- Reaction score

- 14,562

I have done the ferment-and-serve thing in 3 Corny kegs so far...Fermenting in kegs is dirt simple; I just connect a QD to the gas port, and run a length of tubing to a blow-off jar. Then near the end of fermentation, I remove the blow off and allow some remaining CO2 to build up inside the keg. This is where spunding with a gauge would be useful, but for now I've been winging it.

I am very intrigued. But the specifics of "near the end" would be something I'd want to know, and without constantly taking samples or having one of those Tilt things, how'd one know?

LudicrousLush

Member

- Joined

- Dec 8, 2018

- Messages

- 9

- Reaction score

- 1

McKnuckle: thank you for sharing that.

I've been thinking of doing this with 1/4 barrel (7.75 gallon) Sanke kegs for a long time. I installed a 4" TC port in one of my Sanke kegs so that I can get into the keg to clean it out and also possibly drop in a chilling coil to control fermentation temps, if I ever go glycol instead of a fridge I now use. Being that I have that port, I could drop in a float ball.

The nice thing about using 1/4 barrel Sankes is that I could up my batch size from 5 gallons to 7 gallons and still have headroom for krausen. Or if I went to 7.5 gallons, I could use a blow off tube like I do now with carboys. 5 gallon batches are a bit small if the beer is good. 10 gallons is kinda too much, for my equipment and to consume in a reasonable time, unless I'm throwing a summer party or it is my house beer. Even then it doesn't warrant me buying larger equipment. However my current equipment would easily make 7 or 8 gallons of wort into the fermentor(s).

I guess I could ferment 4.75 gallons in Corny kegs... it is just that the batch size is getting a bit small. I guess I could ferment 2 x 4 gallons per batch. My boil kettle is 11 gallons.

One of the big turn offs for me with conical fermentors is that very few are really airtight at pressure and almost none are built to handle the pressure necessary to carbonate beer for serving.

I don't get what all the fuss is about with them if you can't use them for serving. Most people don't do a secondary fermentation and autolysis isn't an issue if the beer is kept cold, so why do you need a conical ? So you can yeast harvest ?

The issue with yeast harvesting is that if you remove a quart of yeast out the bottom, you let a quart of air in at the top, unless you have some headspace at the top and you have it filled with pressurized CO2. But you don't want to be draining yeast out of a pressurized vessel either. So I don't understand the benefit of a conical.

Yeast autolysis is not an issue at serving temps. It might be at higher temps, I'd have to do some research on that.

I love the work and CO2 that your practice saves. I also love that the finished beer doesn't get exposed to any oxygen what so ever. I t can't get any fresher than that.

Have you done any dry hopping with your set up / practice ?

FWIW, I've been straining the hops, hot break and even some of the cold break out of my wort by recirculating it into a BIAB bag in the boil kettle at the end of the boil. It removes a lot of debris from the wort, makes for super clean wort. I hardly have any debris in my carboys at the end of fermentation, maybe 1/2" of yeast. Details here and here.

FYI, Brulosophy has tested the effect of fermentation headspace on beer quality, here. However, what I think they also inadvertently tested was the effect of only partially filling an unpurged serving keg as well.

It turns out that fermentation produces a TON of CO2. 5 gallons of 1.050 wort will produce between 11 and 15 cubic feet of CO2, depending on attenuation. Fermenting in a half full vessel (2-3 gallons of headspace) shouldn't cause any oxidation issues at all. Source

BTW, your process is called Unitanking.

Brewman,

If you are worried about getting air into a conical while harvesting yeast, just use a yeast brink...

Thank you for the great post!

McKnuckle

Well-Known Member

I am very intrigued. But the specifics of "near the end" would be something I'd want to know, and without constantly taking samples or having one of those Tilt things, how'd one know?

There are some things in brewing that I get very detailed about, and others where I'm prepared to go 80% of the way and call it good. Mash pH is one... I plug numbers into 2 or 3 different water tools, come up with my additions, and go for it. But I don't own a pH meter and never plan to.

So far it's been that way for natural CO2 in the keg. I'm not seeking to literally carbonate my beer that way. I realize I would need precision instruments to do so. I'm just looking to get a head start, and to remove all attachments from the keg as soon as possible. So when I say "near the end," I mean perhaps 7 days in - when the bubbles in my blow-off jar are quite slow.

That being said, this 10 psi inline check valve thing that someone linked to in another thread seems VERY simple and intriguing. He attaches it to his blow-off hose and puts it in the StarSan jar. When the bubbles slow way down, he removes it altogether, since that theoretically indicates ~10 psi of remaining pressure, good enough to partially carb the beer.

- Joined

- Nov 26, 2013

- Messages

- 7,661

- Reaction score

- 14,562

this 10 psi inline check valve thing that someone linked to in another thread seems VERY simple and intriguing

Agreed.

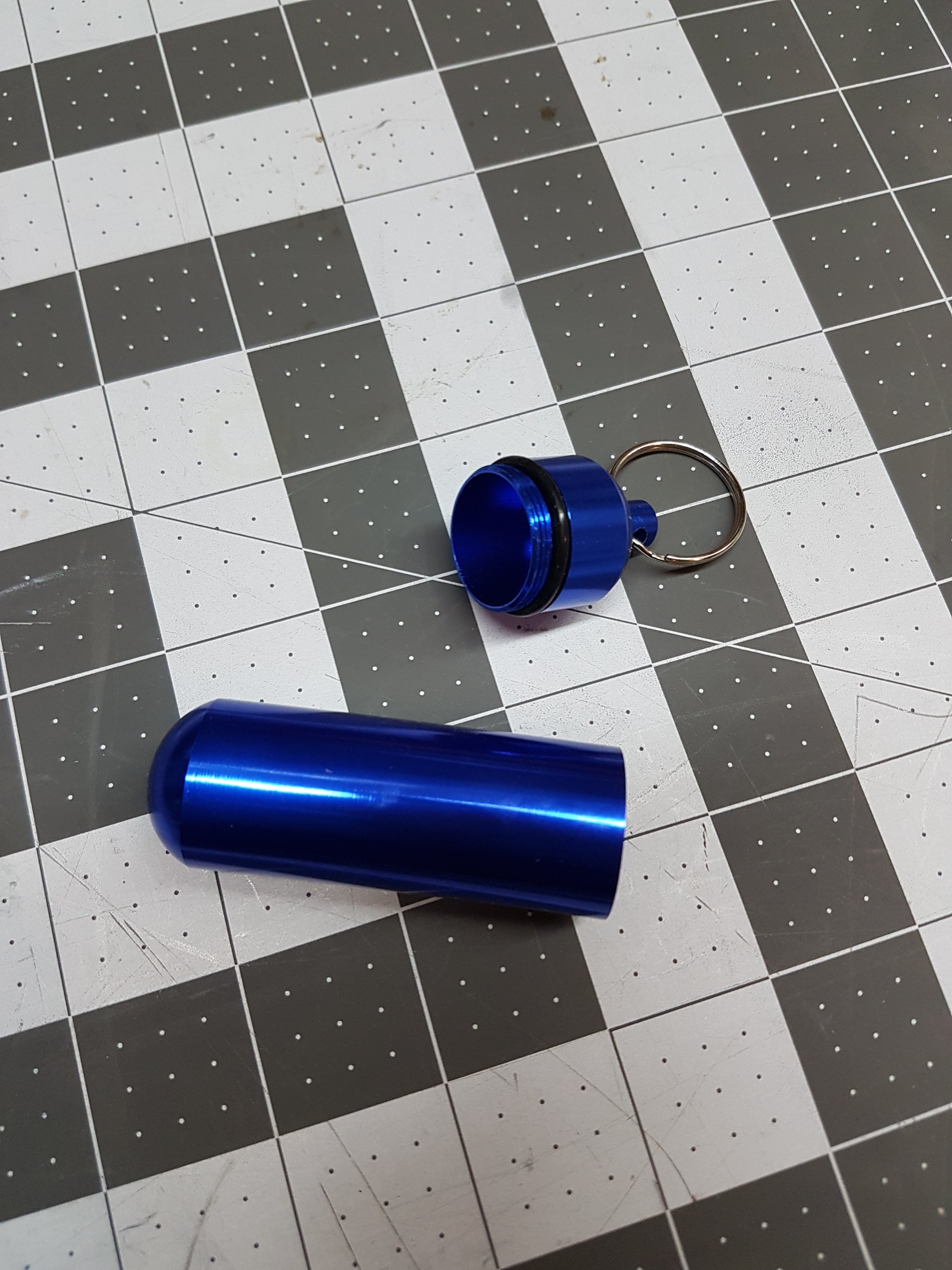

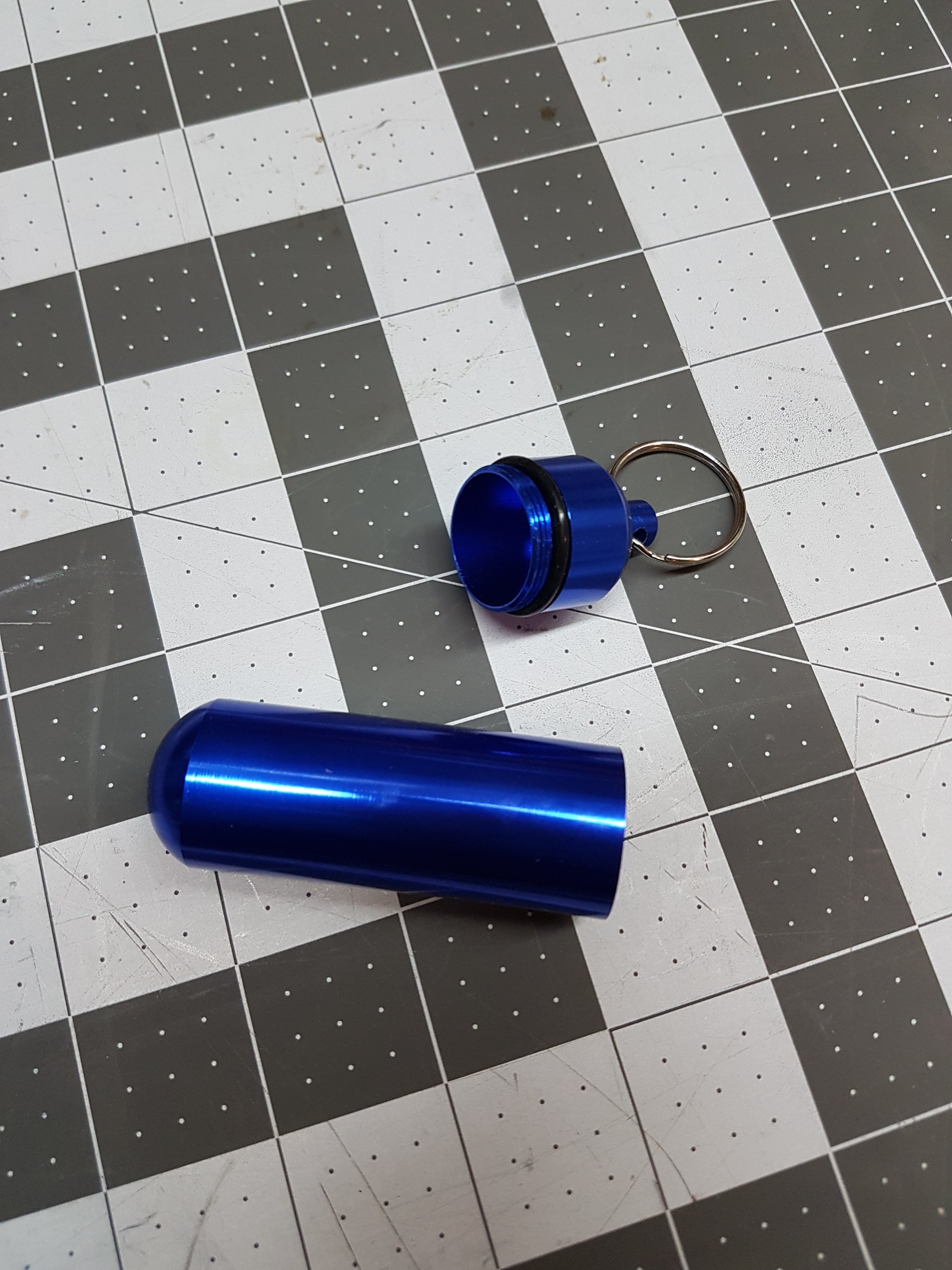

Lookie what I bought today for $4 each at a local hardware store.

They are aluminum.

How do I test this without cutting the dip tube? All the gas in tubes I have are small diameter and won't work as a product tube.

They are aluminum.

How do I test this without cutting the dip tube? All the gas in tubes I have are small diameter and won't work as a product tube.

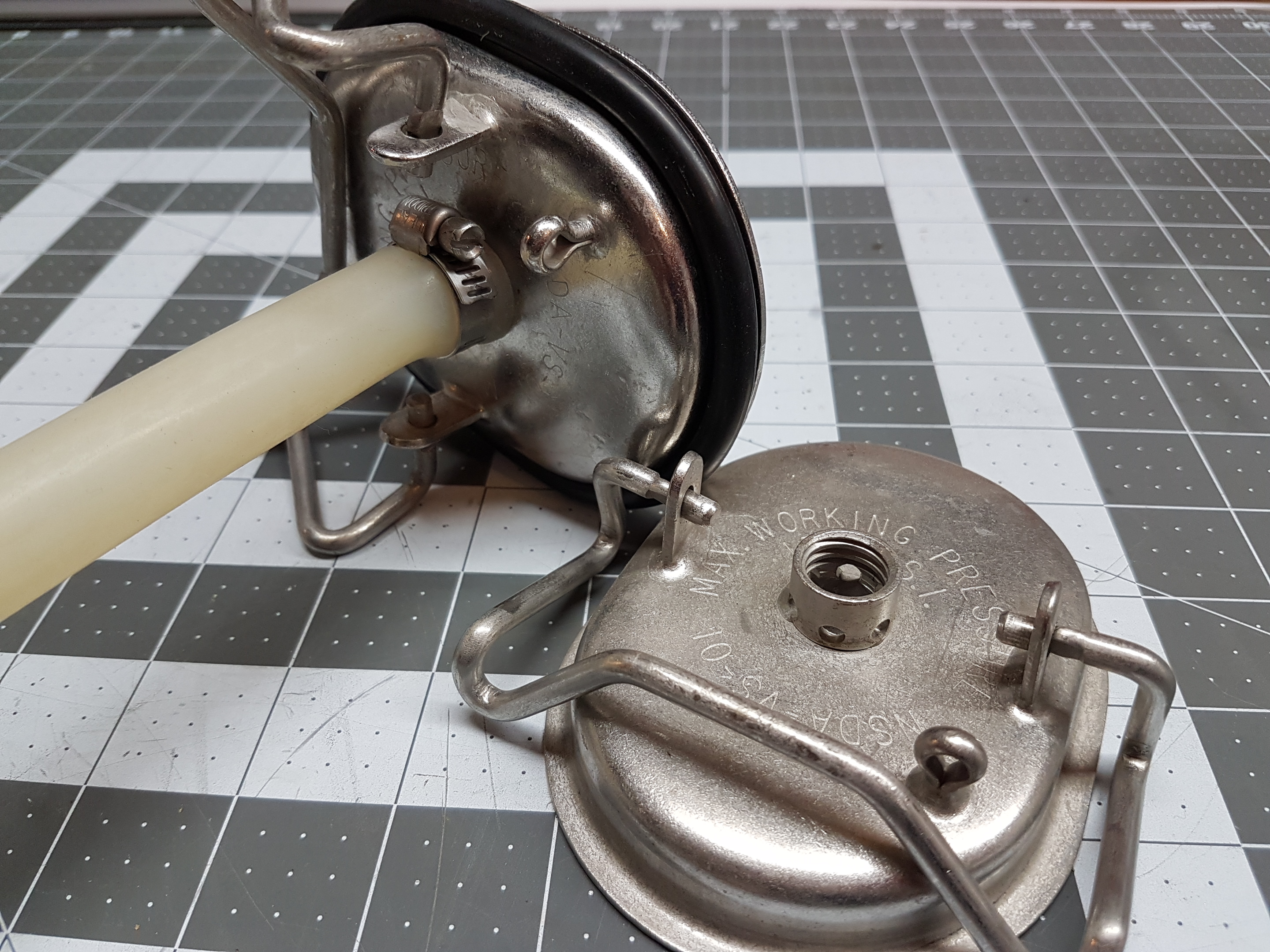

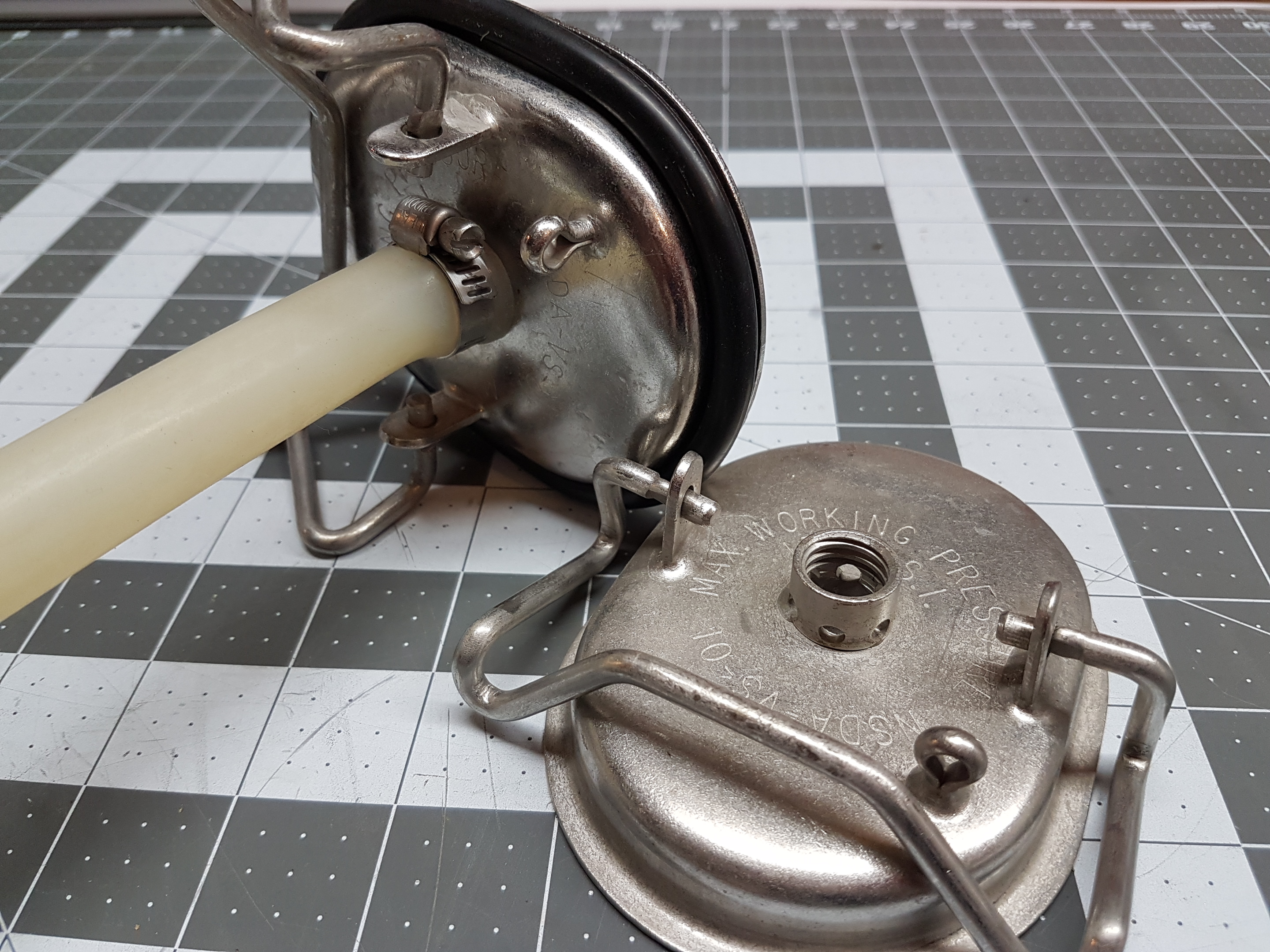

If you can find the right lids, it is simple to attach a blow off tube to a corny.

I can make a nicer system, but this will do for now.

How about this, for example. The lockdown bail just clears it. The ID is big enough to drop in a small carb stone on 3/8" hose, so after fermenting you could carb without removing the lid. Could put a spud on the gas port too and just cap off the lid port.

A 1.5" TC works as well, but that is overkill, right ?

I can make a nicer system, but this will do for now.

How about this, for example. The lockdown bail just clears it. The ID is big enough to drop in a small carb stone on 3/8" hose, so after fermenting you could carb without removing the lid. Could put a spud on the gas port too and just cap off the lid port.

A 1.5" TC works as well, but that is overkill, right ?

Last edited:

The aluminum capsules in my post above do not have enough buoyancy to float a short length of SS tubing and vinyl hose. The yellow one will float it, but just. The blue one sinks to the bottom.

The other issue is that vinyl hose is too stiff. These pickups will need silicon hose.

The other issue is that vinyl hose is too stiff. These pickups will need silicon hose.

Try this:

http://think.gusius.com/diy-keg-floating-dip-tube

Discussed in this thread:

https://www.homebrewtalk.com/forum/...ube-for-clear-beer.647284/page-2#post-8342101

and here:

https://www.homebrewtalk.com/forum/threads/serve-and-ferment-from-keg.661932/#post-8536671

I made several of them, and my regular dip tubes are now collecting dust. I use them for both fermenting in kegs and serving from kegs, sometimes with transfer and sometimes without.

http://think.gusius.com/diy-keg-floating-dip-tube

Discussed in this thread:

https://www.homebrewtalk.com/forum/...ube-for-clear-beer.647284/page-2#post-8342101

and here:

https://www.homebrewtalk.com/forum/threads/serve-and-ferment-from-keg.661932/#post-8536671

I made several of them, and my regular dip tubes are now collecting dust. I use them for both fermenting in kegs and serving from kegs, sometimes with transfer and sometimes without.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 3

- Views

- 638

- Replies

- 39

- Views

- 773

- Replies

- 0

- Views

- 275