danpshack

Member

- Joined

- Jan 15, 2019

- Messages

- 16

- Reaction score

- 2

Folks,

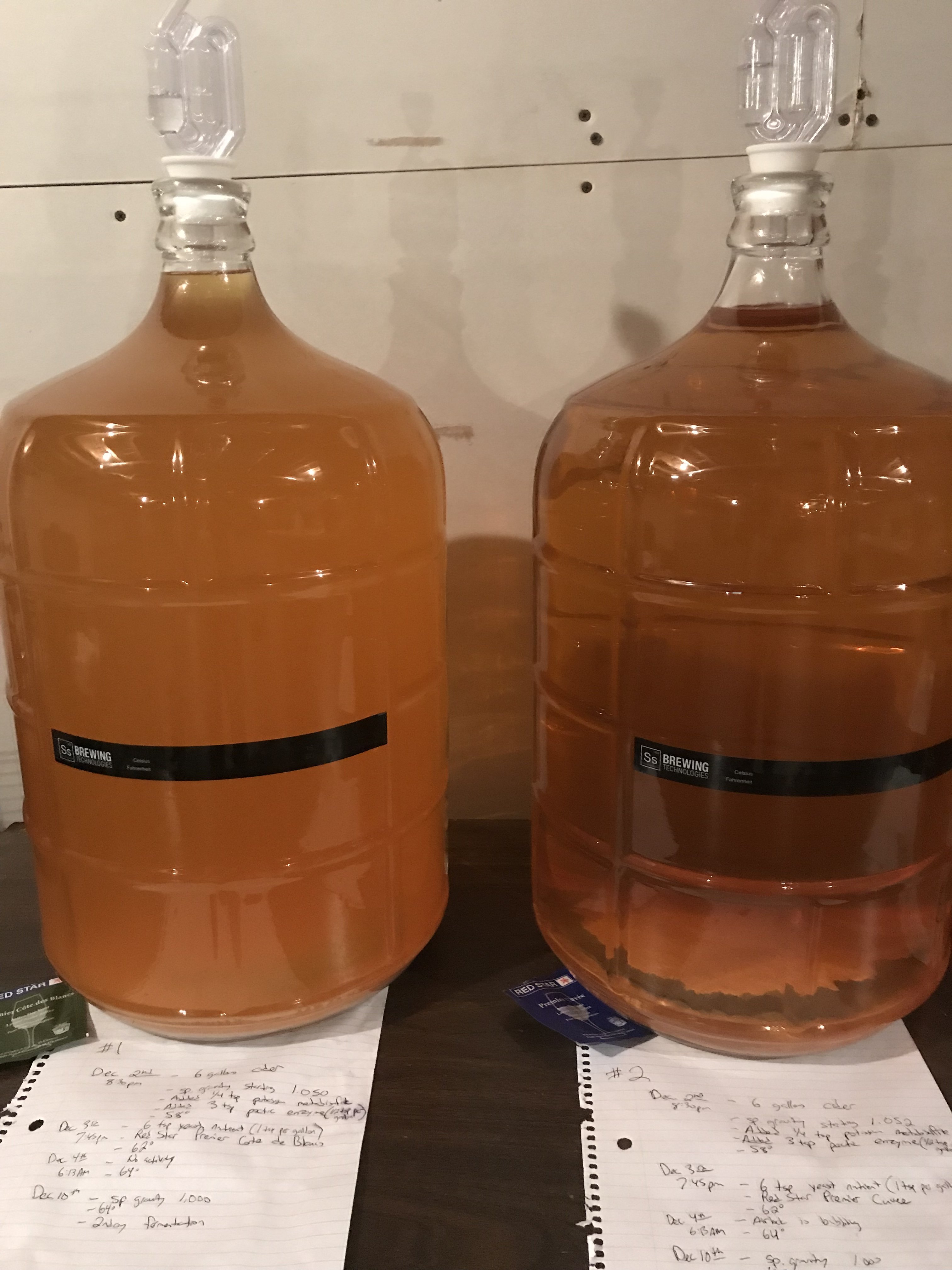

This is the first time I've tried making hard cider. I have a carboy that was clear after primary, then turned hazy two weeks into secondary. There are also small bubbles appearing in the neck of the carboy. I used fresh pressed cider from a local orchard. I used starsan with everything and vodka in the airlock. I don't believe contamination is a factor. I first added Potassium Metabisulfite and let it sit 12 hours, then added pectic enzyme and let it sit another 12 hours. I then pitched red star yeast with yeast nutrient. Primary went great and then I racked to secondary. The cider was very clear then all of a sudden went hazy. I have 4 other carboys in secondary and they are not experiencing the same issue. Could this be MLF that I've read about? Should I let it sit? I'd like it to be clear before bottling. I plan on bottling in another month and adding carbonation, final result a dry carbonated cider. Any help is much appreciated, thank you.

This is the first time I've tried making hard cider. I have a carboy that was clear after primary, then turned hazy two weeks into secondary. There are also small bubbles appearing in the neck of the carboy. I used fresh pressed cider from a local orchard. I used starsan with everything and vodka in the airlock. I don't believe contamination is a factor. I first added Potassium Metabisulfite and let it sit 12 hours, then added pectic enzyme and let it sit another 12 hours. I then pitched red star yeast with yeast nutrient. Primary went great and then I racked to secondary. The cider was very clear then all of a sudden went hazy. I have 4 other carboys in secondary and they are not experiencing the same issue. Could this be MLF that I've read about? Should I let it sit? I'd like it to be clear before bottling. I plan on bottling in another month and adding carbonation, final result a dry carbonated cider. Any help is much appreciated, thank you.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)