sjm1027

Active Member

- Joined

- Nov 22, 2015

- Messages

- 27

- Reaction score

- 2

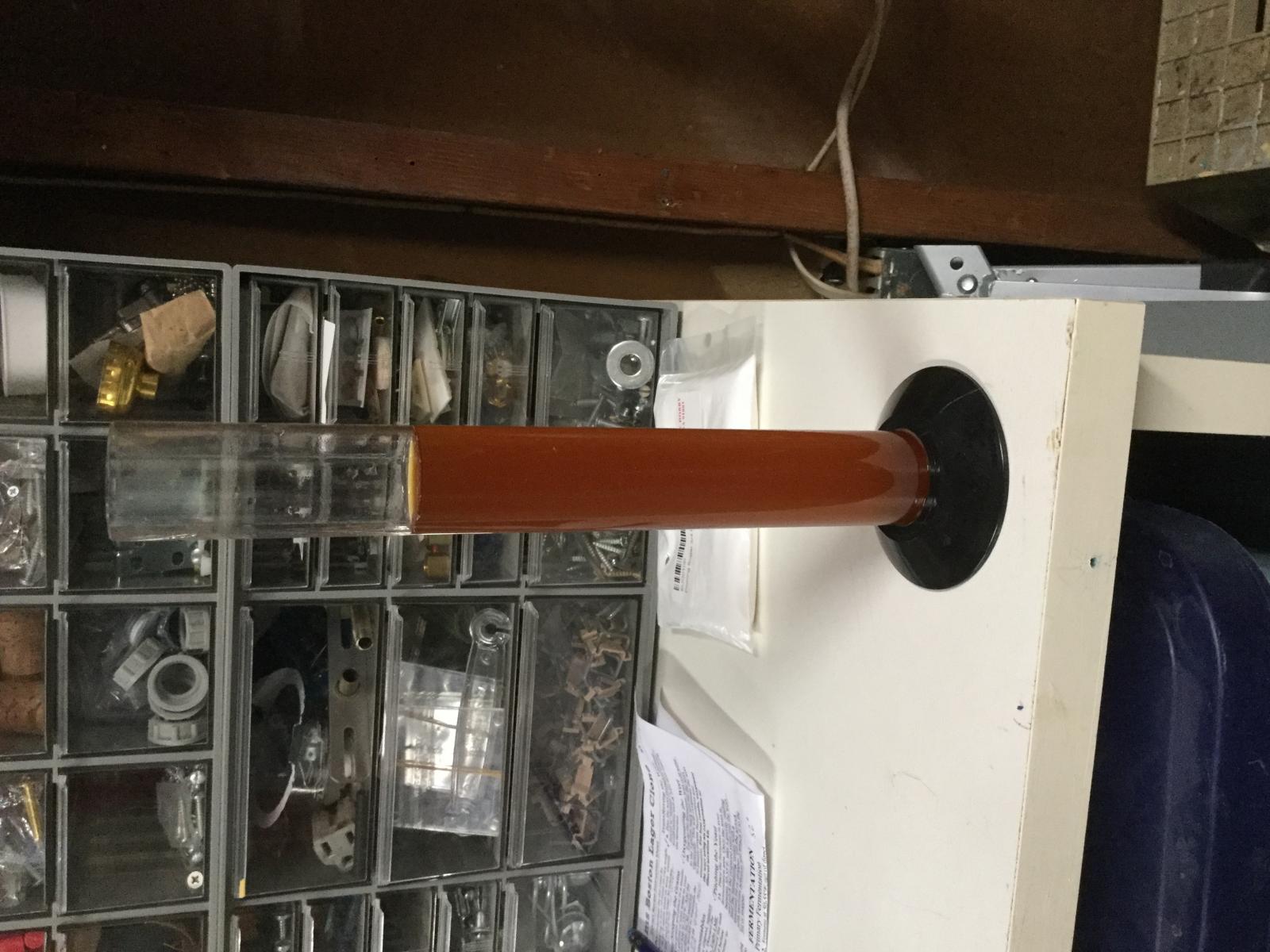

Made my first 5 gallon batch yesterday. I am using the fast ferment conical fermenter but my question has to do with the process.

I cracked my grain and put it in muslin and steeped for 30 minutes

Why wouldn't the instructions tell you to also put the hops pellets and Irish Moss in separate muslin bags as well? I even called the place I purchased the kit and asked after the fact and he said it wasn't necessary??

I ran into a problem when adding my wort to the fermenter... The wort wouldn't go through the funnel with a the strainer. I kept the strainer on but had to first pour the wort into a mesh bag then pour that through the funnel strainer. It still took me a ton of time. What do you guys do? I can't believe you spend 1 hour + pouring 5 gallons of wort into the fermenter? Or maybe I'm wrong?

Thanks

Steve

I cracked my grain and put it in muslin and steeped for 30 minutes

Why wouldn't the instructions tell you to also put the hops pellets and Irish Moss in separate muslin bags as well? I even called the place I purchased the kit and asked after the fact and he said it wasn't necessary??

I ran into a problem when adding my wort to the fermenter... The wort wouldn't go through the funnel with a the strainer. I kept the strainer on but had to first pour the wort into a mesh bag then pour that through the funnel strainer. It still took me a ton of time. What do you guys do? I can't believe you spend 1 hour + pouring 5 gallons of wort into the fermenter? Or maybe I'm wrong?

Thanks

Steve