MVCL

Member

Hi all,

I have, over the years, got a tremedous amount of tips from HBT and I think it is time for me to start posting and participating. So, here goes ...

I have been doing partial boil extract on and off over the last few years and a buddy of mine inspired me to move to BIAB. However, the winters in Syracuse are too cold for me to consider brewing outdoors with propane, so I went with this eBIAB system. Up until a week ago, we were still waking up to -8* temperatures.

I did a trial run with only water a few weeks ago and it turned the kitchen into a sauna. I literally had to wipe down all the walls as they had condensation running down them in rivers. That is why you see a couple of attempts at trying to control the vapors in the pics. Fan worked surprisingly well, I didnt think it would get the two foot deep thunderhead clinging to the ceiling, but it did. Other than the vapors, the trial went smoothly.

I was pleased with the first brew (Malty Brown Ale AG kit from MoreBeer) yesterday with the new system. I added a little bit more Dextrose since I have a few pounds left over from when I was bottling, kegging now.

I crushed the malt at the default gap setting with the Barley Crusher mill. I figured I would lower the gap for my next brew if I didnt hit my target gravity, however to my surprise, I hit 1.067 but was only expecting 1.062. My volumes were dead on thanks to the water only test run that allowed me to predict boil off. So, I apparently was able to extract a little more from the grains than BeerSmith estimated @ 73% mash efficiency.

The only thing that really needs improvement is the chiller. I have a small immersion chiller that I used for my 2.5 gallon extract boils that struggled to cool ~6 gallons to 75* over 45 minutes with 46* water. Not good. Ill have to work on that part. Thinking about this ... http://jadedbrewing.com/collections/counterflow-chillers/products/the-jaded-cfc I like that it can be cleaned easier than a plate chiller. Water in B'ville is very hard so I'm concerned that a plate chiller wouldn't last very long or might suffer from clogs as the hard water went to work on it over time.

Fermenter is happily burbling away, yeah.

Pics of the day ...

15.5 gallon High Gravity eBIAB setup

Heating Element

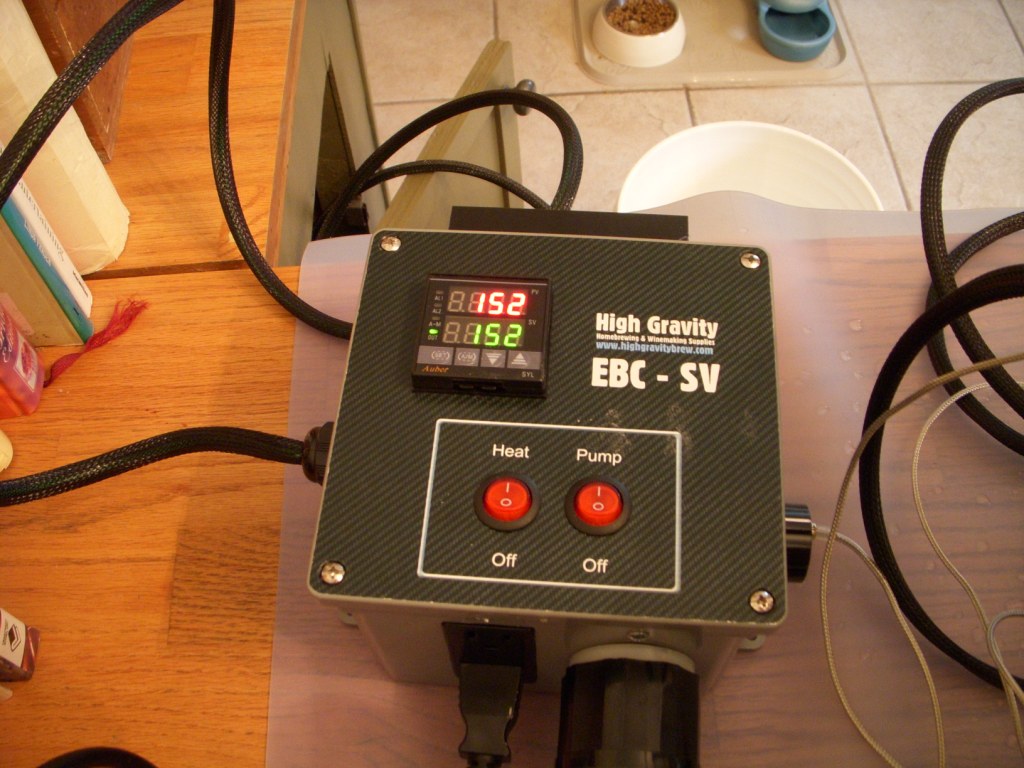

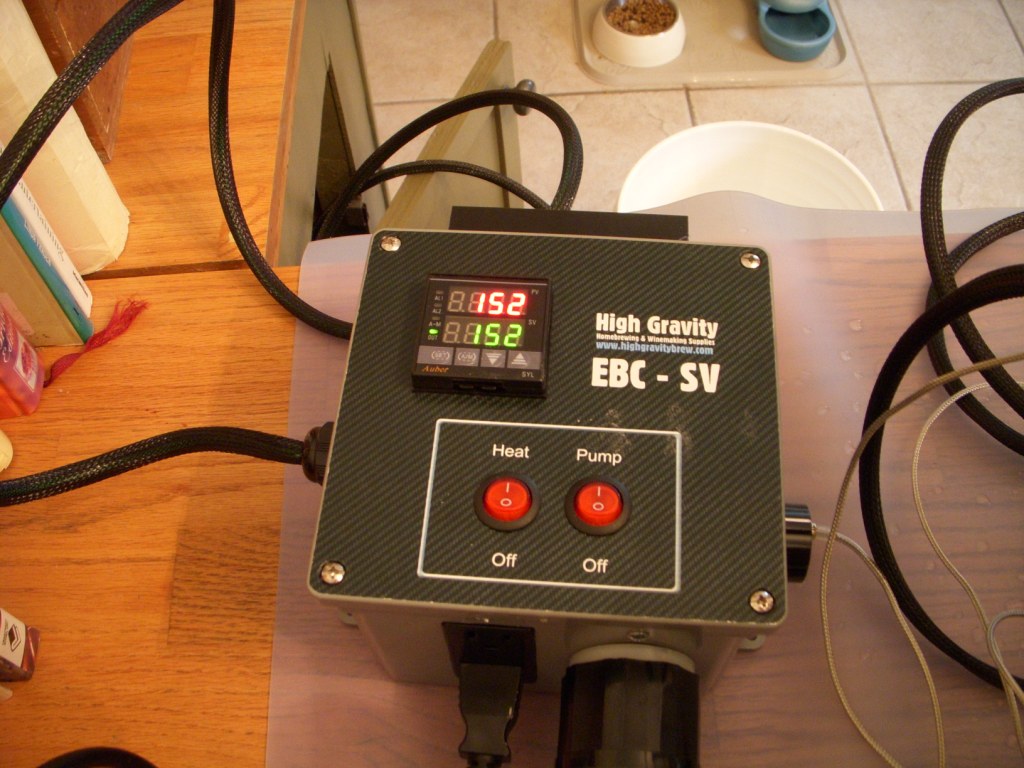

Controller holding temp during mash

Using bike stand to drain grains

Attempt To Control Boil Vapor - FAIL

Attempt To Control Boil Vapor - Succeed

Yeah, I know the towel half covering the pot was a long shot, but if it worked and I didn't have to open the window then it wold have been great.

Other than the chiller, the only surprise was the amount of trub. Quite a bit more than extract brewing. I think I got more than I would like in the fermenter and will have to pay more attention to it for the next batch.

Can't wait to find out how it ends up.

I have, over the years, got a tremedous amount of tips from HBT and I think it is time for me to start posting and participating. So, here goes ...

I have been doing partial boil extract on and off over the last few years and a buddy of mine inspired me to move to BIAB. However, the winters in Syracuse are too cold for me to consider brewing outdoors with propane, so I went with this eBIAB system. Up until a week ago, we were still waking up to -8* temperatures.

I did a trial run with only water a few weeks ago and it turned the kitchen into a sauna. I literally had to wipe down all the walls as they had condensation running down them in rivers. That is why you see a couple of attempts at trying to control the vapors in the pics. Fan worked surprisingly well, I didnt think it would get the two foot deep thunderhead clinging to the ceiling, but it did. Other than the vapors, the trial went smoothly.

I was pleased with the first brew (Malty Brown Ale AG kit from MoreBeer) yesterday with the new system. I added a little bit more Dextrose since I have a few pounds left over from when I was bottling, kegging now.

I crushed the malt at the default gap setting with the Barley Crusher mill. I figured I would lower the gap for my next brew if I didnt hit my target gravity, however to my surprise, I hit 1.067 but was only expecting 1.062. My volumes were dead on thanks to the water only test run that allowed me to predict boil off. So, I apparently was able to extract a little more from the grains than BeerSmith estimated @ 73% mash efficiency.

The only thing that really needs improvement is the chiller. I have a small immersion chiller that I used for my 2.5 gallon extract boils that struggled to cool ~6 gallons to 75* over 45 minutes with 46* water. Not good. Ill have to work on that part. Thinking about this ... http://jadedbrewing.com/collections/counterflow-chillers/products/the-jaded-cfc I like that it can be cleaned easier than a plate chiller. Water in B'ville is very hard so I'm concerned that a plate chiller wouldn't last very long or might suffer from clogs as the hard water went to work on it over time.

Fermenter is happily burbling away, yeah.

Pics of the day ...

15.5 gallon High Gravity eBIAB setup

Heating Element

Controller holding temp during mash

Using bike stand to drain grains

Attempt To Control Boil Vapor - FAIL

Attempt To Control Boil Vapor - Succeed

Yeah, I know the towel half covering the pot was a long shot, but if it worked and I didn't have to open the window then it wold have been great.

Other than the chiller, the only surprise was the amount of trub. Quite a bit more than extract brewing. I think I got more than I would like in the fermenter and will have to pay more attention to it for the next batch.

Can't wait to find out how it ends up.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)