Using DeathBrewer's Easy Partial Brewing Technique:

5 lb Pale Malt (2 Row)

1 lb Crystal Malt (40)

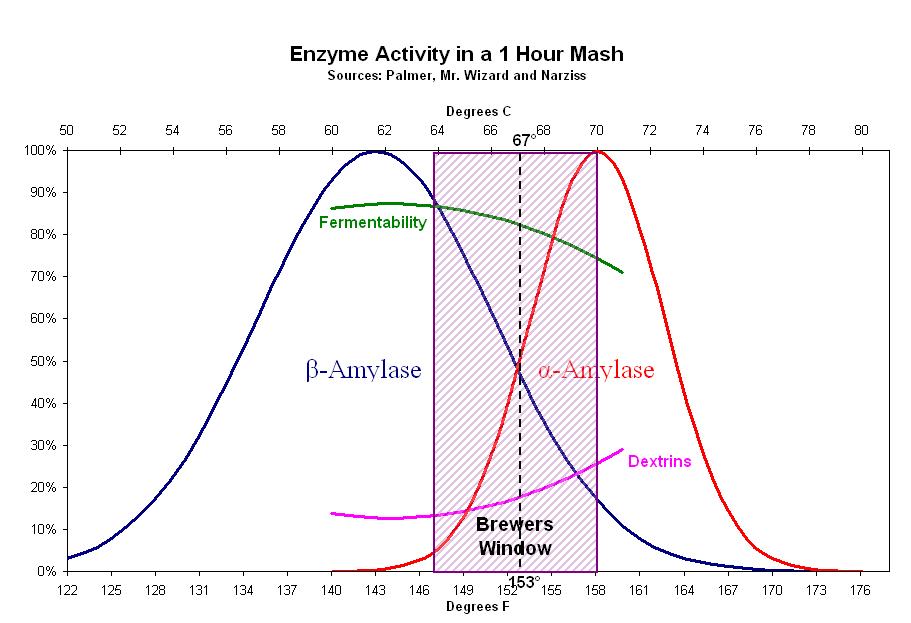

Mash in 2.5 Gallons Strike Temp 160F, settled in on 152F and now sitting about 45 minutes

Sparge in 1.5 Gallons 160F for 10 to 15 min for additional conversion

3 lb Light DME

0.25 lb Cane Sugar

60 minute Boil

1 oz Cascade 8.6% @ 60 min

1 oz Cascade 8.6% @ 10 min

1 oz Cascade 8.6% @ Whirlpool

1 oz Citra 13% @ Whirlpool

Will be topped up to 4.5-4.75 gallons for Estimated OG Between 1.062 and 1.065

Dry Hop:

1 oz Citra and/or 1 oz Cascade 7 days.

Thoughts?

5 lb Pale Malt (2 Row)

1 lb Crystal Malt (40)

Mash in 2.5 Gallons Strike Temp 160F, settled in on 152F and now sitting about 45 minutes

Sparge in 1.5 Gallons 160F for 10 to 15 min for additional conversion

3 lb Light DME

0.25 lb Cane Sugar

60 minute Boil

1 oz Cascade 8.6% @ 60 min

1 oz Cascade 8.6% @ 10 min

1 oz Cascade 8.6% @ Whirlpool

1 oz Citra 13% @ Whirlpool

Will be topped up to 4.5-4.75 gallons for Estimated OG Between 1.062 and 1.065

Dry Hop:

1 oz Citra and/or 1 oz Cascade 7 days.

Thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)