Yes, you'd have a horrible trub/yeast mess to deal with unless you moved beer from fermenting keg to serving keg. Or unless you have a way to dump the trub as with a conical with a bottom dump valve.

I actually have the ideal situation to ferment under pressure with my Ss Uni Tank system. I have fermented under pressure and made the exact same beer not fermented under pressure. I have to report that I cannot tell a difference between the two.

Some say that fermenting under pressure ends up relating in some fashion to lower oxygen brewing. I know Brulosophy did a side by side with a pressure ferment compared to a non-pressure ferment. I don't think the differences were apparent while the beer is young, but maybe the pressure fermented version stays fresher longer. Not sure to be honest.

Here's the theory on it: oxidation at any point post-fermentation is a bad thing. This is especially true for hoppy beers. When you transfer from fermenter to keg, you are almost certain to introduce O2 during that time. You can reduce it, but unless you're doing things like absolutely purging the keg w/ CO2, purging the lines before transfer, figuring out how to get that last bit of air out of a purged keg...you're introducing O2.

It also is important for long-term storage. If your kegs are kicking after 2 or 3 weeks, probably not that important. Some have reported kegging a 10 gallon batch in two 5-gallon kegs, drank one, the other sat, waiting. After literally months, they report the "waiting" keg was indistinguishable from the early beer. OK, I guess. No reason to not believe it.

[reply interlude: I know some of this sounds faintly ridiculous. I'm relating the theory. Anyone bothered by this, please save the brickbats for someone else. Not you, Morrey.

]

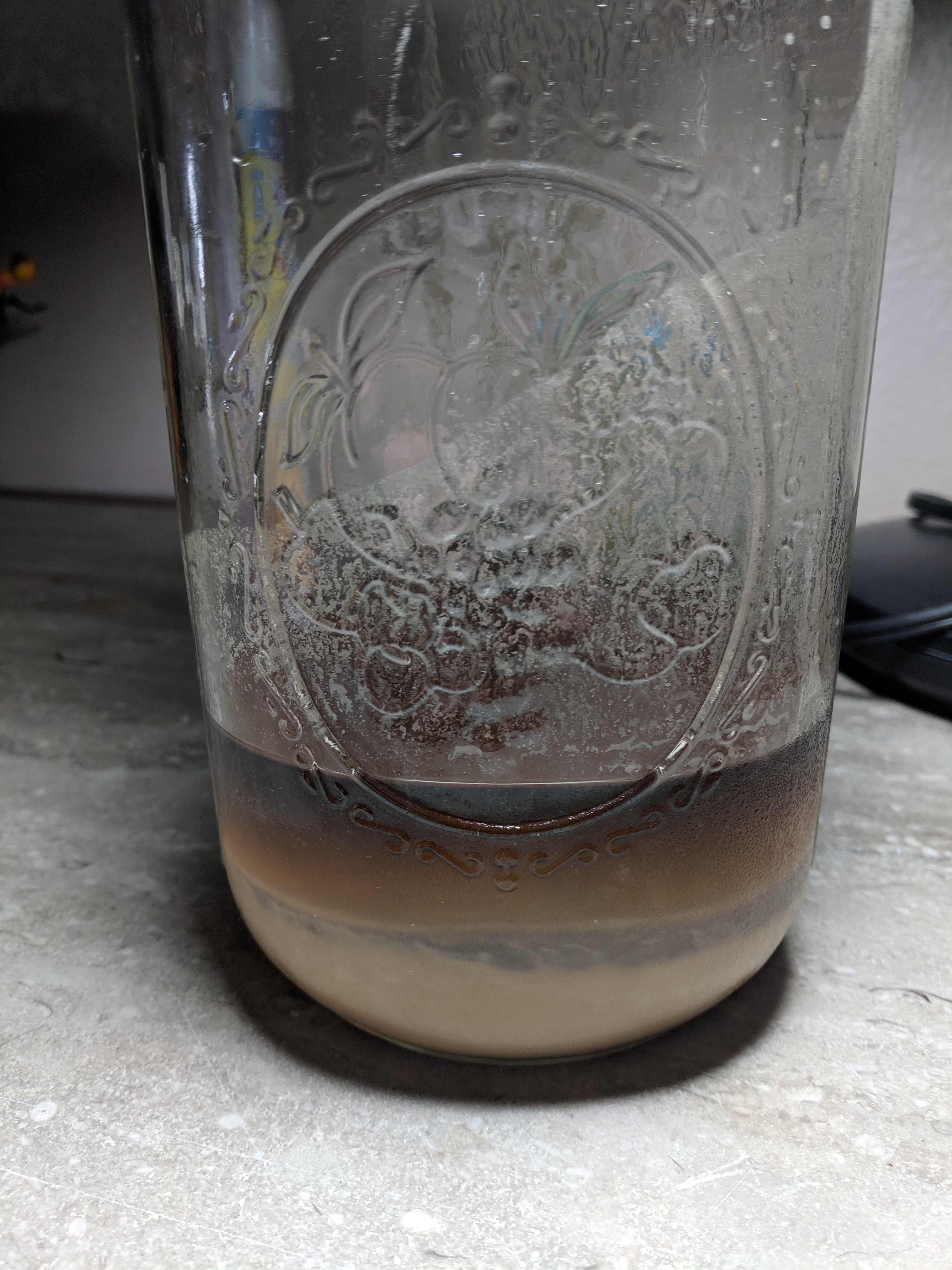

One technique to get the O2 out of the equation and avoid all the trub/yeast in the bottom of the keg is to do keg spunding. Transfer the fermenting wort into the keg when there are about 5 points of gravity remaining, and let it finish in the keg. If your expected FG is 1.012, you'd transfer when gravity is about 1.017. This is analogous to bottle conditioning with priming sugar.

Spunding this way means any O2 that makes its way into the keg will be consumed by the yeast. It will also carbonate the beer, which is nice. But, there are some challenges with this approach. One is knowing when you have 5 gravity points remaining. You can keep taking samples, but everyone knows the cost of that in beer, convenience, and so on. Another is an internal device to measure gravity like Tilt, but that's $140 or so.

Another alternative is to use a spunding valve which will bleed off excess pressure if you xfer the wort with more than 5 points remaining.

The whole idea is to get the O2 out of the keg. Now, there's one more consideration that may cause some heads to explode. Why not simply force-carb at the end?

The LODO answer is that the CO2 we use is not pure. Even if 99.5 percent CO2, if that .5 percent is air, 21 percent of

that is O2, so you're forcing a small amount of O2 into the beer when force carbing.

Does that matter enough to matter? My guess is not, but some in the LODO community say it is, which is why they're carbonating in the keg instead of force carbing.

*****************************

I've been working with LODO techniques, trying to see if it's worth the effort. It's a work in progress. I've produced some pretty good beer this way, including one I'd consider stunning. But there are a lot of moving parts, and IMO the process is rather involved.

I've been struggling to get this to work well on the hot side; I've made some progress, and the flavor of the wort going into the BK is much, much more pronounced, much sweeter-tasting to me, than the wort from a normal brew process.

I just bought a Spike CF10 conical fermenter which will allow me to pressure-ferment, carbonate before xfering to the keg, pressure transfer, clear trub from the beer, etc. Morrey is doing this very well with his system, and I'm hoping I can get to that level. We've actually been tag-teaming this, he's been working to get the O2 out of the cold side, I've been working on the hot side. He's further along than I am.

******************************

Does any of this matter? Can we taste the difference? That actually depends on two things, whether we keep O2 out of the process on the hot side, accentuating flavors, and whether we can keep it out on the cold side, reducing or preventing oxidation after fermentation.

If all we do is focus on the cold side, we'll never see a difference that emerges on the hot side. Many, brulosophy for instance, and Morrey's experience above, suggest it's not something one can perceive. But that depends on who is doing the tasting. I have issues with how brulosophy tests, given there's generally little or no control over what people were drinking just prior to testing (does a hoppy IPA render taste buds numb?).

I'm willing to accept--lots of anecdotal evidence--that some people can perceive oxidation flavor changes while others cannot. So results of all that effort might, quite possibly, be impossible for some people to taste.

But others can. I have a friend with a tremendous palate--he can taste things I cannot. I have him test my beers, seeing if he can detect any off flavors. He gets beer, I get feedback. I figure if my beer can pass his palate's standards, it's probably going to be good for almost everybody.

In the end, people have to taste and decide for themselves. I've had enough success with LODO techniques to keep pushing forward. But others may well decide it's not worth the time and effort given the results. As usual....

...YMMV

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)