curruscanis

Active Member

- Joined

- Dec 7, 2015

- Messages

- 39

- Reaction score

- 8

Hello all, I would like to introduce a system that I have been working on to get any comments / questions from this forum. I started this project after attempting to make a brewpi-remix system work for my needs with limited success. The problem that I ran into with the brewpi-remix was mainly that I was running a glycol system and it was not really designed with that in mind. Lbussy, was more than helpful in attempting to assist me in getting a system that would work and I was able to make it work, but I found it was just to fussy and had too much that I didn't need.

So I created my own, I am currently testing this in an "Alpha" semi production right now.

My Fermentation equipment used with this is two SSbrewtech 1/2 barrel Unitanks with internal glycol cooling coils and external heat pads, an SSbrewtech Glycol Chiller.

The Control system is configured with multiple temperature sensors, one for each Unitank, one for Glycol, and currently an extra that I am using for ambient air or a future bright tank.

Since a picture is worth a thousand words here are the pictures of the built hardware and screen shots of the web interface.

10.1" Touchscreen interface and LCD monitoring

Bottom of the unit - power, heating and cooling 12v DC ports for each unitank - Temp sensor connectors

Next, screenshots of the web interface for each of the screens:

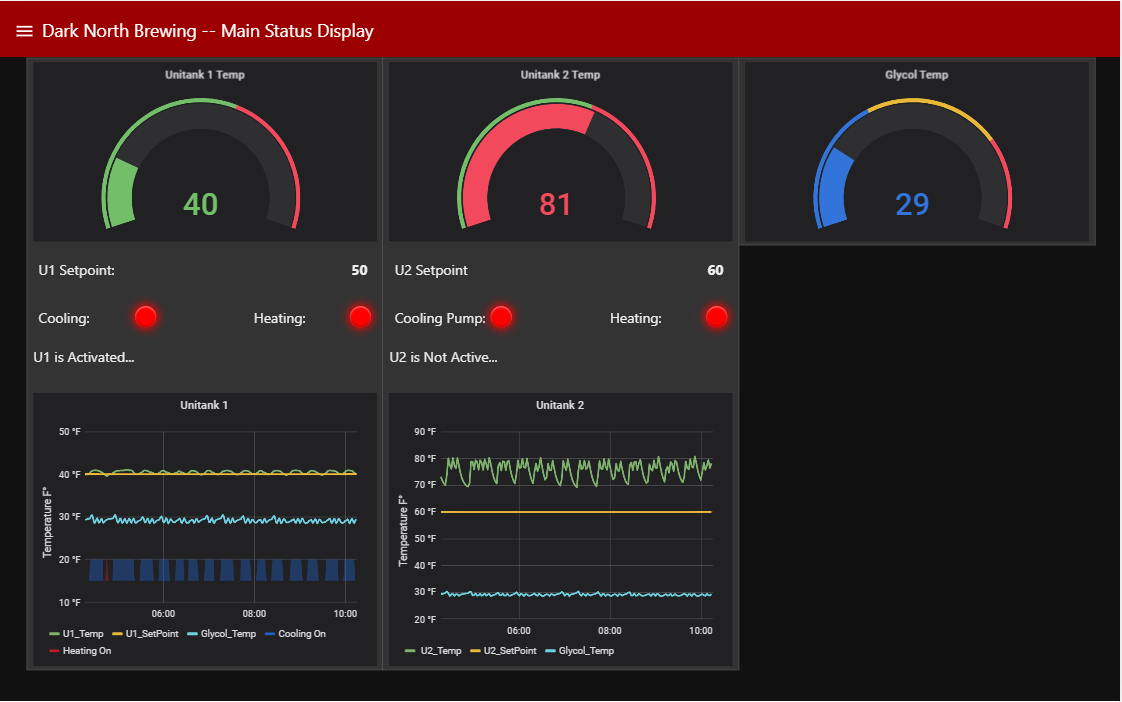

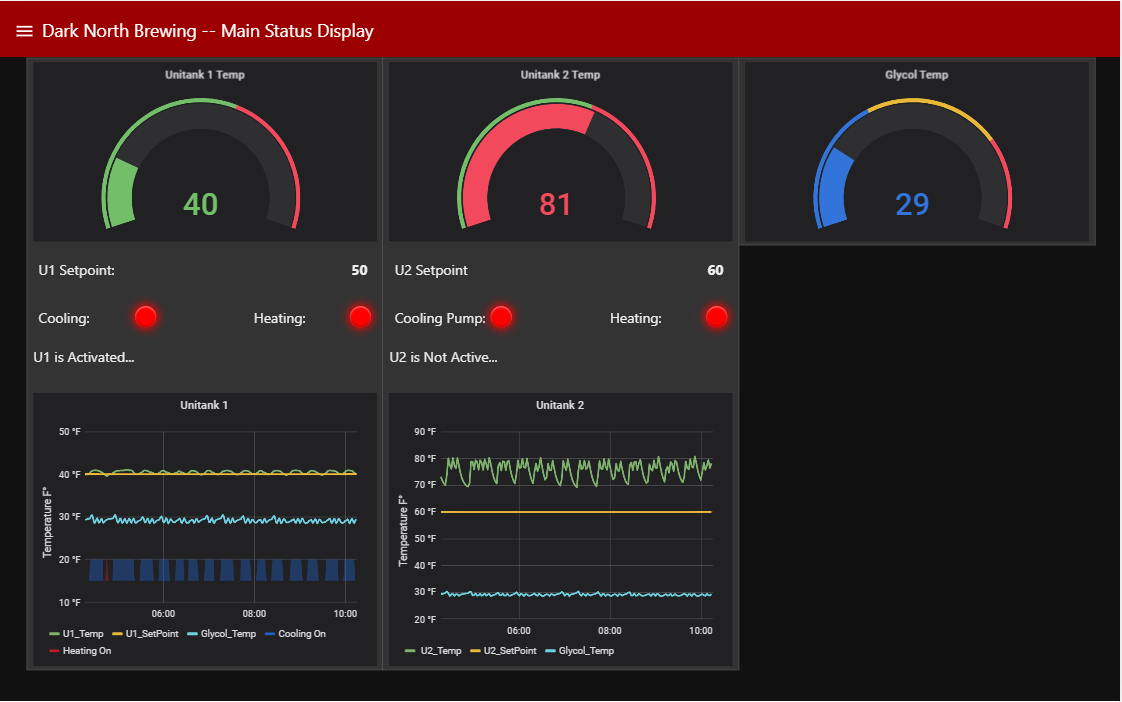

Main Status Display screen - overview of all temps and last 6 hours of the Unitanks.

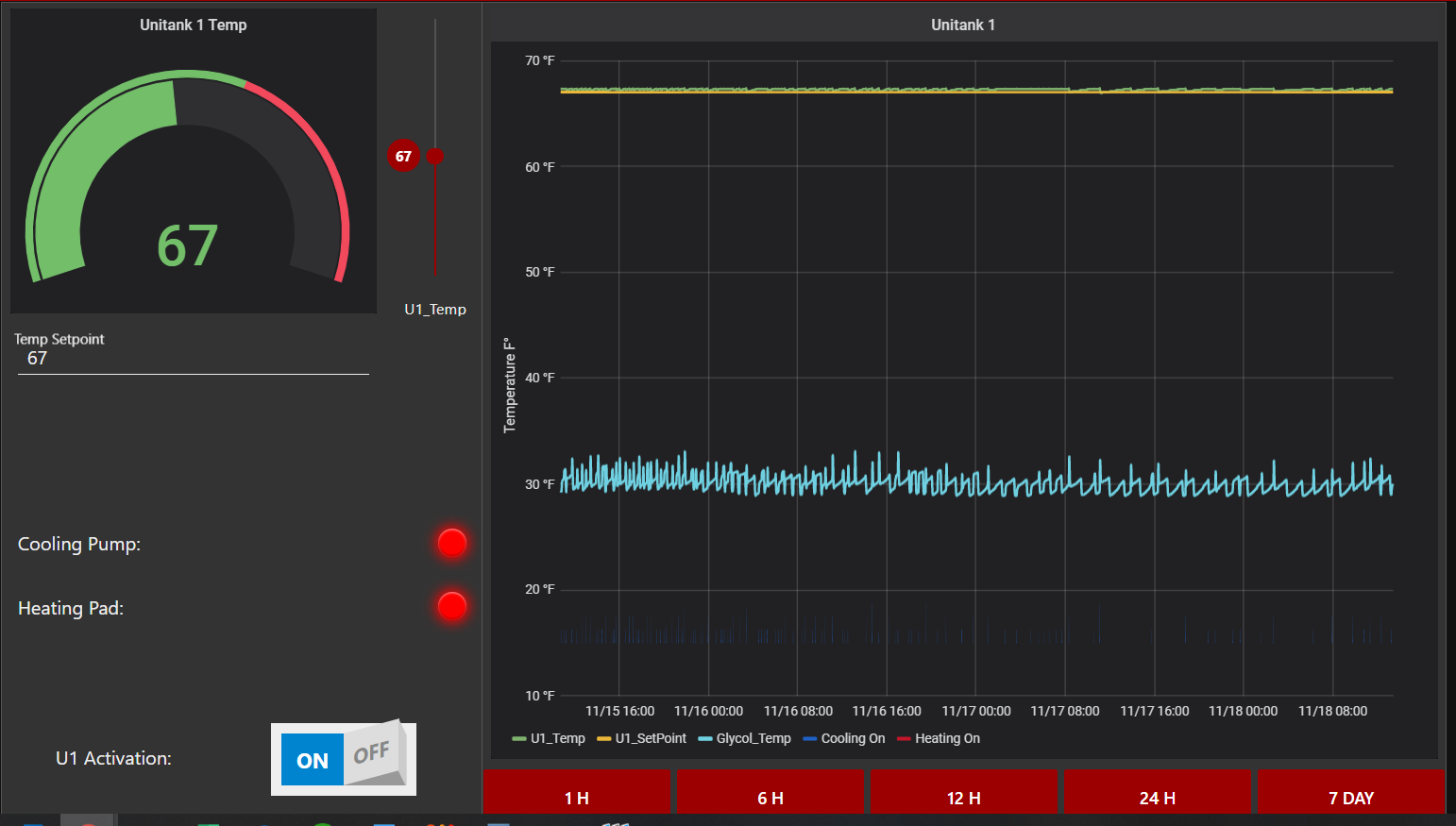

Unitank 1 configuration and monitoring interface - This screen is for activation of the Heating/Cooling system on the tank. Setting of the setpoint of the temperature desired and indicators for if the heating/cooling system is currently running as well as current temperature and graph of various temperature readings over a selectable time increment.

1 Hour selected

6 Hours selected

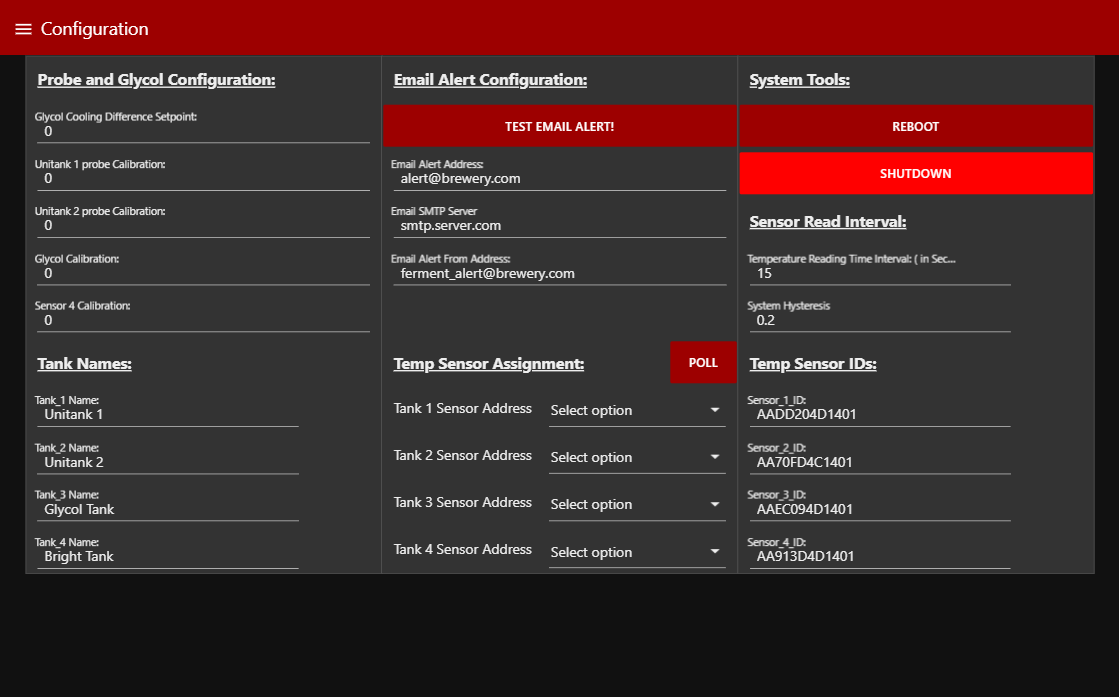

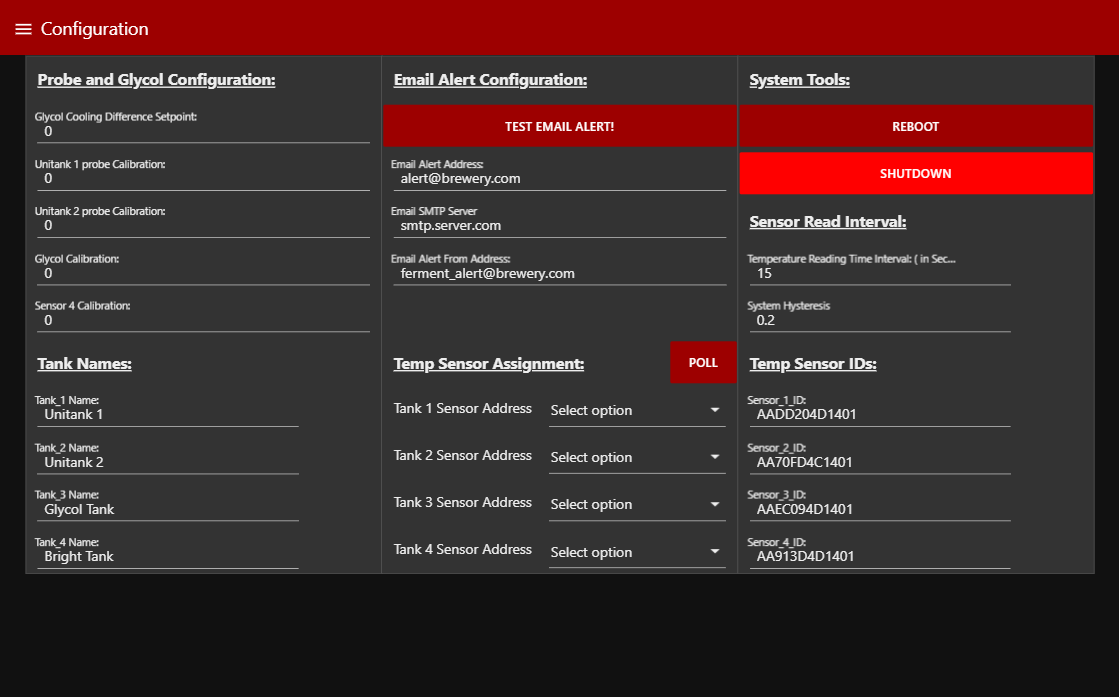

Configuration screen - used to define given variables, alerting, hysteresis settings, temp sensor allocation and the ability to reboot / shutdown the system.

Thank you for any comments or questions on this Fermentation Control System, it is a work in progress and I plan on moving to a "Beta" test where I do a full run with a beer next week.

The computer in the system is a Raspberry Pi, tested with both 3 and 4 hardware versions. The data is stored in a database and displayed using a full feature web based interface. Other hardware includes a 12 volt power transformer for the pumps and heating systems - relays to turn on various systems, digital temperature sensors, 10.1" touchscreen interface for direct control as well as a 4x20 LCD display for reading temp if the larger screen is asleep. Remote systems can log into the web page and control from anywhere via browser.

The cooling system is glycol based using the SSbrewtech Glycol chiller with a 12 volt pump per Unitank that is powered / controlled by the Fermentation Control System.

The heating system uses the 12 volt heat pads supplied by the SSbrewtech FTSS system - The FTSS system is not used as it is replaced by the Fermentation Control System.

Currently my tests have been with a 1/2 barrel unitank full of water and running it through scenarios of holding a given temp as if I was brewing. E.g. holding at 65 degrees F for 2 days - raise / lower temp to another set point like cold crashing to 38 degrees F ( I did 38 not 34 due to using water... I didn't want to cause a freeze ). Raise temp of the Unitank above ambient and hold for more than a day. Each of these tests has been successful and the system appears very stable.

Thanks again!

So I created my own, I am currently testing this in an "Alpha" semi production right now.

My Fermentation equipment used with this is two SSbrewtech 1/2 barrel Unitanks with internal glycol cooling coils and external heat pads, an SSbrewtech Glycol Chiller.

The Control system is configured with multiple temperature sensors, one for each Unitank, one for Glycol, and currently an extra that I am using for ambient air or a future bright tank.

Since a picture is worth a thousand words here are the pictures of the built hardware and screen shots of the web interface.

10.1" Touchscreen interface and LCD monitoring

Bottom of the unit - power, heating and cooling 12v DC ports for each unitank - Temp sensor connectors

Next, screenshots of the web interface for each of the screens:

Main Status Display screen - overview of all temps and last 6 hours of the Unitanks.

Unitank 1 configuration and monitoring interface - This screen is for activation of the Heating/Cooling system on the tank. Setting of the setpoint of the temperature desired and indicators for if the heating/cooling system is currently running as well as current temperature and graph of various temperature readings over a selectable time increment.

1 Hour selected

6 Hours selected

Configuration screen - used to define given variables, alerting, hysteresis settings, temp sensor allocation and the ability to reboot / shutdown the system.

Thank you for any comments or questions on this Fermentation Control System, it is a work in progress and I plan on moving to a "Beta" test where I do a full run with a beer next week.

The computer in the system is a Raspberry Pi, tested with both 3 and 4 hardware versions. The data is stored in a database and displayed using a full feature web based interface. Other hardware includes a 12 volt power transformer for the pumps and heating systems - relays to turn on various systems, digital temperature sensors, 10.1" touchscreen interface for direct control as well as a 4x20 LCD display for reading temp if the larger screen is asleep. Remote systems can log into the web page and control from anywhere via browser.

The cooling system is glycol based using the SSbrewtech Glycol chiller with a 12 volt pump per Unitank that is powered / controlled by the Fermentation Control System.

The heating system uses the 12 volt heat pads supplied by the SSbrewtech FTSS system - The FTSS system is not used as it is replaced by the Fermentation Control System.

Currently my tests have been with a 1/2 barrel unitank full of water and running it through scenarios of holding a given temp as if I was brewing. E.g. holding at 65 degrees F for 2 days - raise / lower temp to another set point like cold crashing to 38 degrees F ( I did 38 not 34 due to using water... I didn't want to cause a freeze ). Raise temp of the Unitank above ambient and hold for more than a day. Each of these tests has been successful and the system appears very stable.

Thanks again!