augiedoggy

Well-Known Member

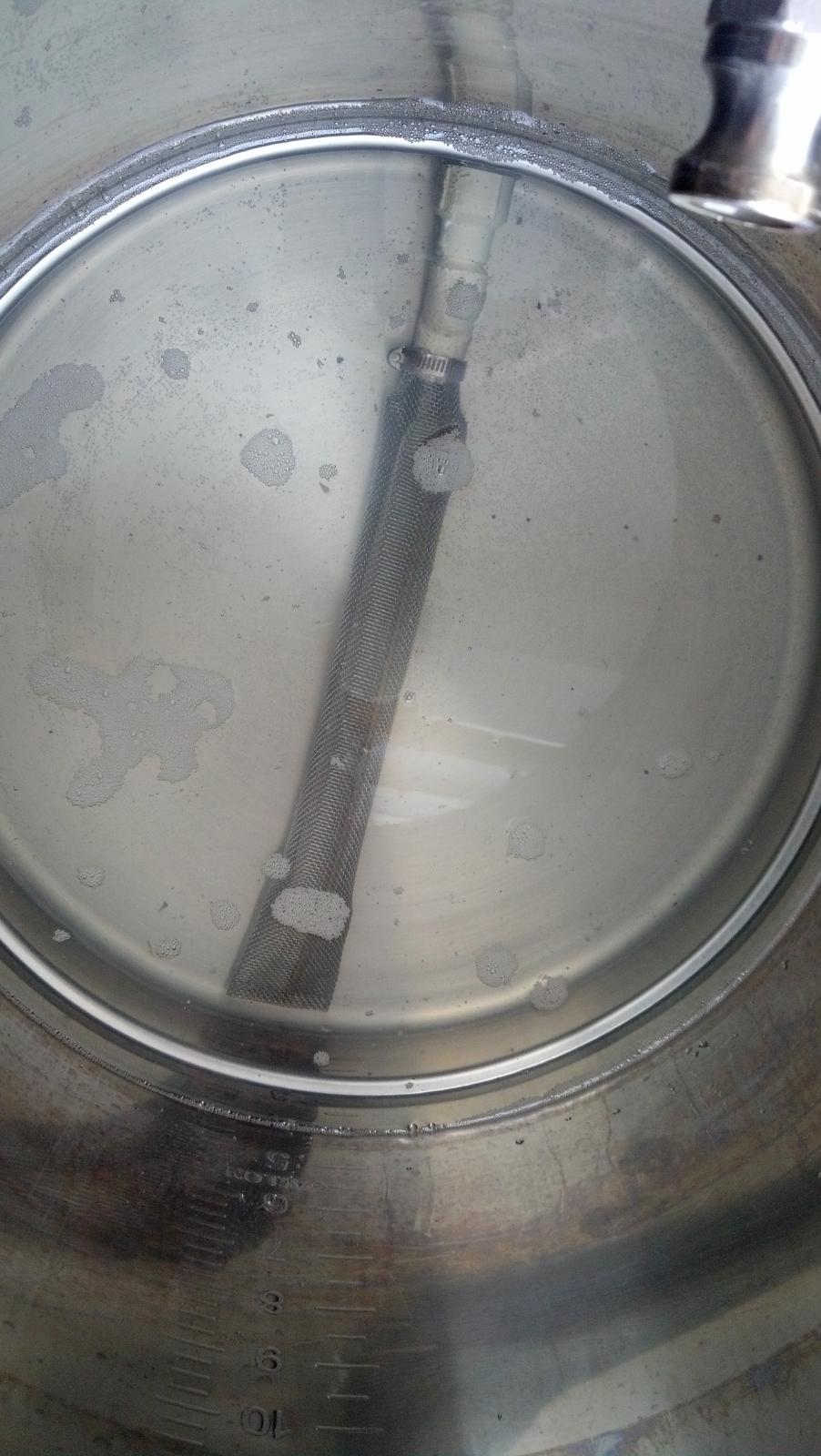

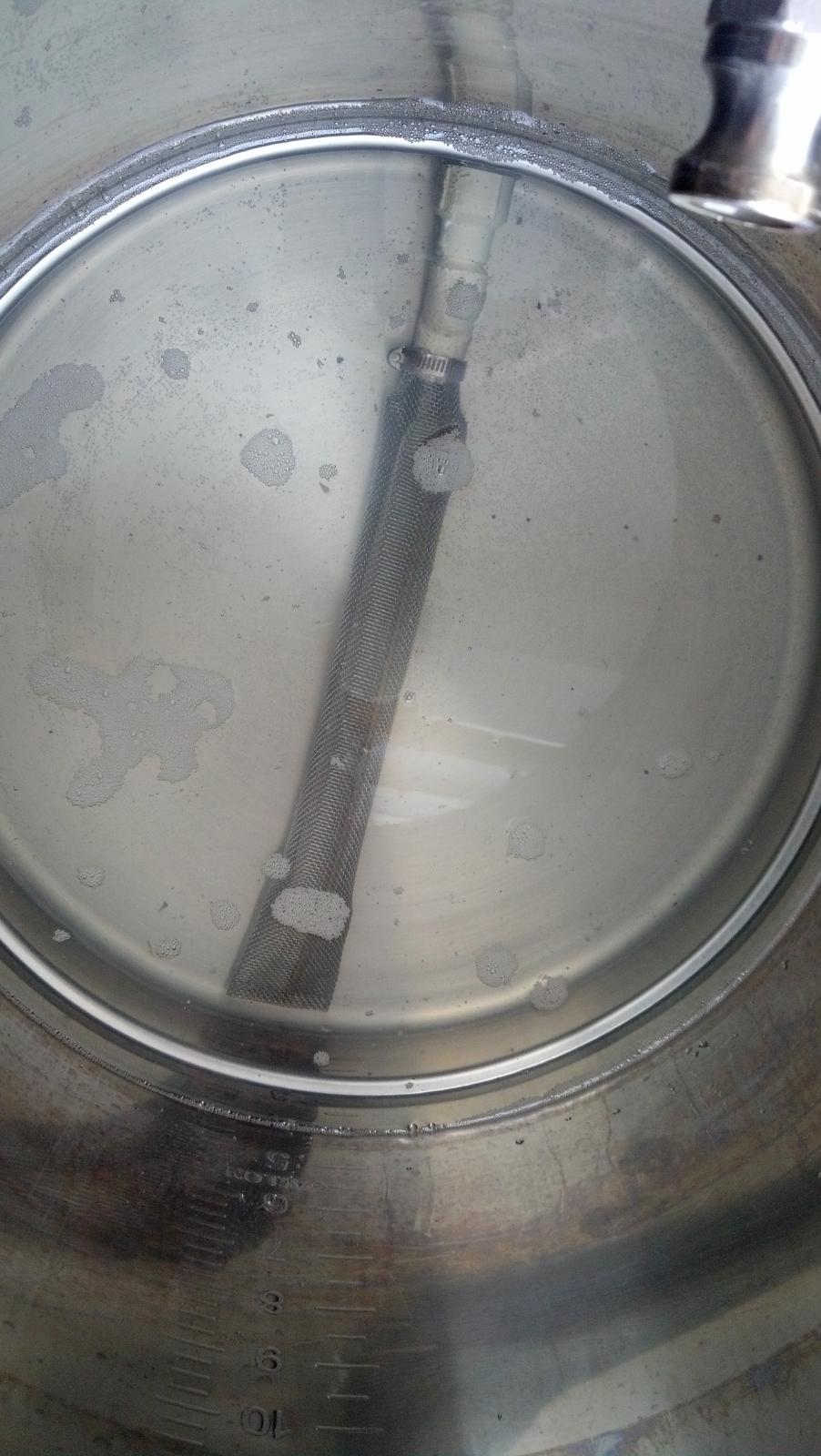

jawilhelm asked for pictures of my mash tun false bottom filtering setup..

here you go

theres water in it because I was experimenting with flow levels with while using a flow switch that will kill the rims heat if I get a stuck sparge.

here you go

theres water in it because I was experimenting with flow levels with while using a flow switch that will kill the rims heat if I get a stuck sparge.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)